Behind the noise and turmoil of Brexit and COVID-19, hauliers are quietly going about the business of finding new ways to reduce the carbon footprint of their fleets. Orbcomm discusses its Fuel Auditor feature and how it helps to reduce emissions.

As fleets have discovered, there is not just one solution to the CO2 emissions challenge. Instead, it is about employing a range of different technologies, equipment, and process improvements which all add up to having the greatest impact.

Within the telematics field, emphasis to date has focused on changing driving behaviour, route planning, and proactive maintenance to cut emissions. Less practised has been the process of fuel auditing to compare the CO2 emissions of individual vehicles, drivers, or even depots, and neither have changes been put in place to change these results.

How it works

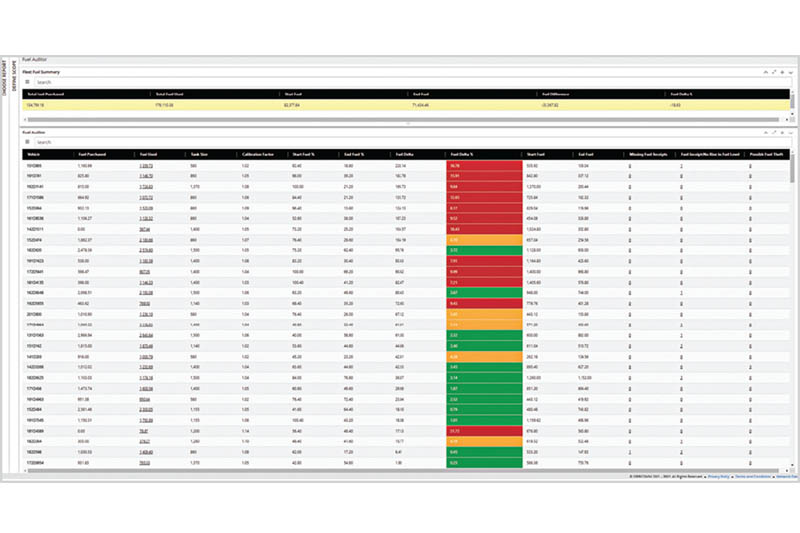

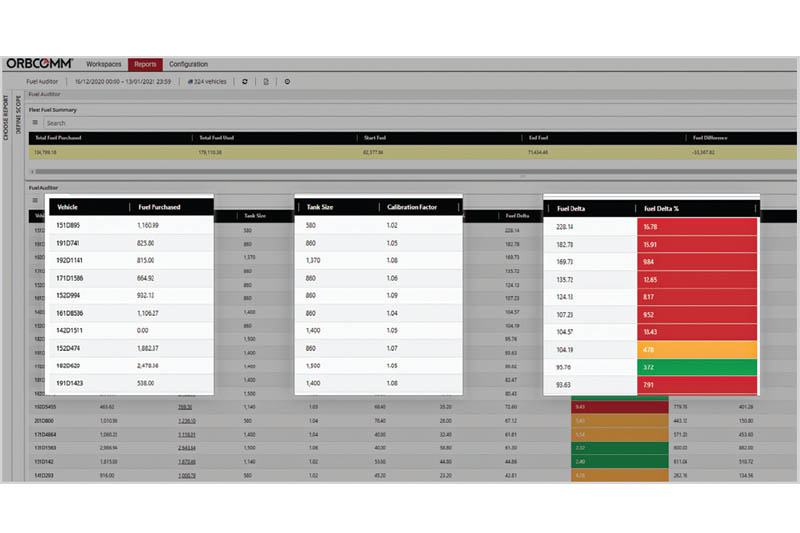

To get to this CO2 calculation, fleet managers need to be confident in the provenance of their data in the first instance. Orbcomm’s Fuel Auditor feature easily achieves this, using actual fuel data to compare fuel purchased with fuel burned.

Fuel purchase data is imported automatically from electronic fuel cards, onsite pumps, or entered manually from fuel receipts, and the amount of fuel burned by each truck over the reporting period is derived from the truck’s CANbus data.

To capture fuel burn data, Fuel Auditor calculates the fuel in the tank at the start of the reporting period, added to the fuel purchased over the period, and subtracts the amount of fuel in the tank at the end of the reporting period.

Residual fuel in truck tanks is calculated at the start and end of the reporting period based on the tank capacity data and the electronic fuel level sensor which are reported every five minutes by Orbcomm.

Applying calibration to ECM fuel burn data

Commentators acknowledge that it can be very difficult to accurately determine the fuel burned by each truck. In these situations, Orbcomm’s Fuel Auditor can apply a software calibration to fuel CANbus data to reflect the real-world fuel economy for each vehicle in the fleet.

Over a short initial period of time, baseline data is gathered and fleets can apply an evidence-based calibration factor in the software to remove any inaccuracy between truck make and models. Orbcomm has multiple years of truck data to aid in this process.

CO2 emission reporting

The Fuel Auditor now has all the data necessary to complete an algorithm, which Orbcomm uses to create an emissions report for every truck in the fleet over any period. Once baselines are established, the fleet can then set CO2 reduction goals to decrease the environmental impact of the fleet.

Orbcomm’s platform also provides additional tools to reduce CO2 emissions. Driver performance scoring compares idling, acceleration, braking, coasting, and anticipation percentages between drivers. So, feedback and coaching can be provided to change driving behaviour that impacts on emission outcomes.

The Maintenance Planner feature can schedule services and inspections based on the time elapsed (e.g. every six months) or distance, to ensure that proactive Maintenance occurs and to avoid negative Emission outcomes.