Wheel alignment equipment specialist Pro-Align outlines the key criteria to consider when investing in a new system.

No matter whether it’s a van, truck, bus, or coach that you’re working on, in order to carry out and sign off any axle and suspension repairs properly, it’s essential that you conduct full wheel alignment. Modern systems, such as the Hunter WAHD commercial vehicle aligner, utilise a number of technologies and innovations designed to make a workshop’s life easier and faster. However, to ensure you invest in the right system for your workshop, there are some key areas you should consider before making a decision.

Number of axles measured

Most commercial vehicle alignment systems don’t provide simultaneous measurement but rely on sensors being moved one axle at a time in a staged process, with the single axle measurements being combined into a final multi-axle reading. This process can be incredibly time consuming whereas systems such as Hunter’s can measure all three axles simultaneously in one easy step, drastically cutting measurement times.

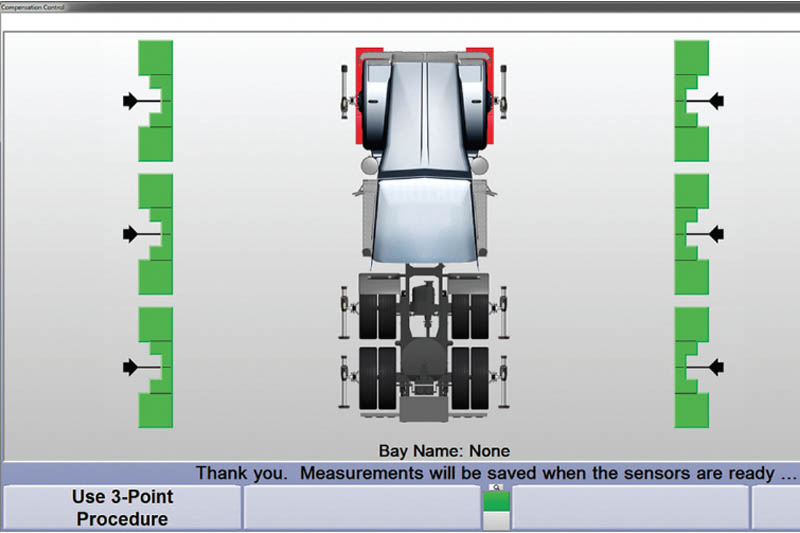

Run out compensation

All vehicle manufacturers recommend conducting a run out compensation as part of an alignment check to eliminate any errors from the mounting of the sensors or the wheel not being true. Two main methods can be adopted to perform the run out compensation. The jacking compensation requires the jacking up and full rotation of the wheel, but this is very time consuming.

Meanwhile, rolling compensation method requires the vehicle to be ‘rolled’ along, rotating the wheels by either a whole or half revolution but newer systems can achieve it in just 400mm. The short roll is achieved with a handheld ‘vehicle pusher’. From a health and safety advantage, this avoids the need to start the engine and drive, but also requires less workshop floor space and improves accuracy of measurement as engine vibrations could interfere with readings.

Frame or axle reference measurement

The geometry of commercial vehicles can be set by two methods. As the name suggests, the frame reference method measures alignment in relation to the frame or chassis of the vehicle. Some manufacturers, such as Mercedes-Benz, consider this to be the preferable method for warranty-based work.

The axle reference method measures alignment in reference to the rear axle and the vehicle’s centreline and thrust line. Most systems can measure via one of these methods, however, the latest Hunter system has the capability and flexibility to do both.

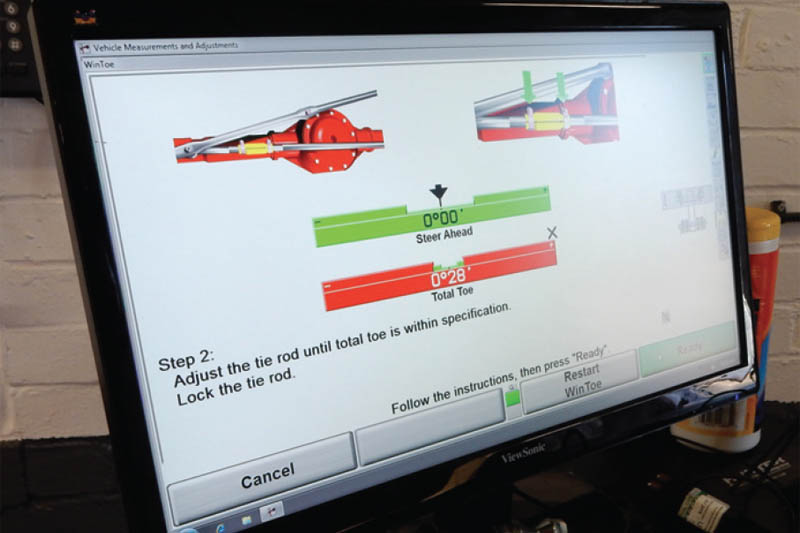

Computer or manual system

Another technical consideration relates to whether you opt for a manual hang-on style gauge or decide to choose wireless sensors or even new camera sensors. Each type has its own benefits but it’s important to think about what you will need to future proof your service, so consideration should be given to factors such as the supply of OEM technical specs and updates, result printouts, system analytics, internet connectivity or cloud capability and aftersales support from the supplier.

Ease of use

Conducting a wheel alignment check on a commercial vehicle can be complicated as the number of axles increase, which is why it’s important to find a system that’s easy to use. Not only will this mean that technicians will be happier using it, delivering a quality job but perhaps more importantly, the charge out time to the customer is realistic.

Time

While a technician’s time is important for the workshop, overall vehicle downtime is of major concern to the vehicle operator. Consequently, servicing time is usually kept to a minimum, so it’s critical to find an alignment system that is accurate but can also do the job in the least amount of time. Some commercial vehicle alignment systems take more than an hour, whereas other more advanced aligners can deliver alignment results in just a few minutes.

Cost

Whilst cost is a consideration of any investment decision, it’s what you want to achieve with it that is important. If you want to incorporate as part of an uplift in service quality and revenue enhancement then spend more, as it will offer a greater return on investment.