Clive Seabrook, CEO of Pro-Align, outlines how the new Hunter commercial vehicle aligner helps workshops provide a better and more profitable service.

Tyre and fuel costs remain two of the most significant items on the minds of commercial vehicle operators and workshops alike. Without their proper management and attention, it could mean the difference between a healthy profit or a painful loss at the end of an already challenging financial year.

Many workshops have long recognised the impact that correct wheel alignment can have on the management of both tyres and fuel. After all, when a truck’s tyres are correctly aligned, tyre life can be extended by as much as 22% and 10% respectively for drive and steer axle tyres.

Furthermore, without the misaligned tyres scrubbing across the road surface, causing additional rolling resistance, some studies have shown that fuel economy can also be boosted by between 2-19% in the worst cases, potentially reducing running costs by tens or even hundreds of thousands of pounds a year – a figure which simply cannot be ignored.

Saving graces

However, with a standard CV alignment check typically taking 12-15 minutes, many workshops feel that they cannot justify the investment in additional labour hours to regularly check a truck’s alignment without any guarantee of potential fuel or tyre wear savings.

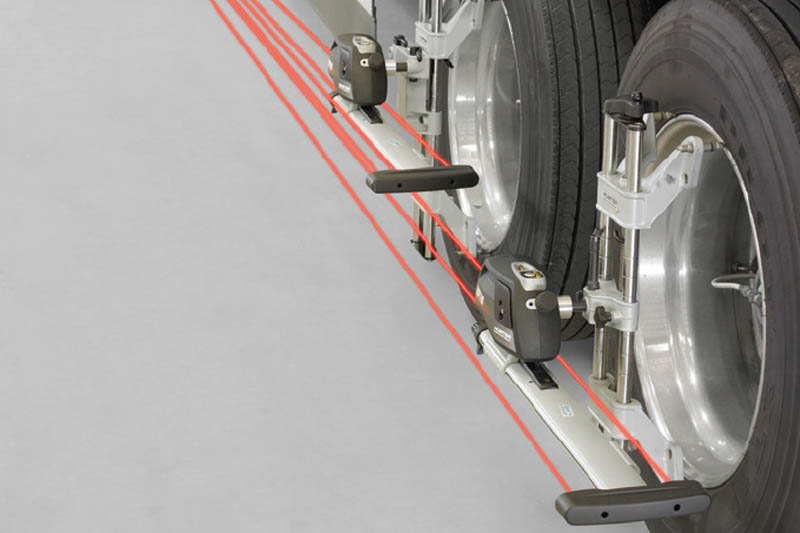

With this in mind, Hunter’s engineers have worked hard to develop a dedicated wheel alignment system for multi-axle trucks which overcomes this challenge. Indeed, the new system allows workshops to perform a three-axle alignment check, including a results printout, in just three minutes.

Given the speed of the system and the potential improvements on operating costs that it can deliver, workshops and operators shouldn’t continue to overlook regular wheel alignment checks for their vehicles.

Added efficiency

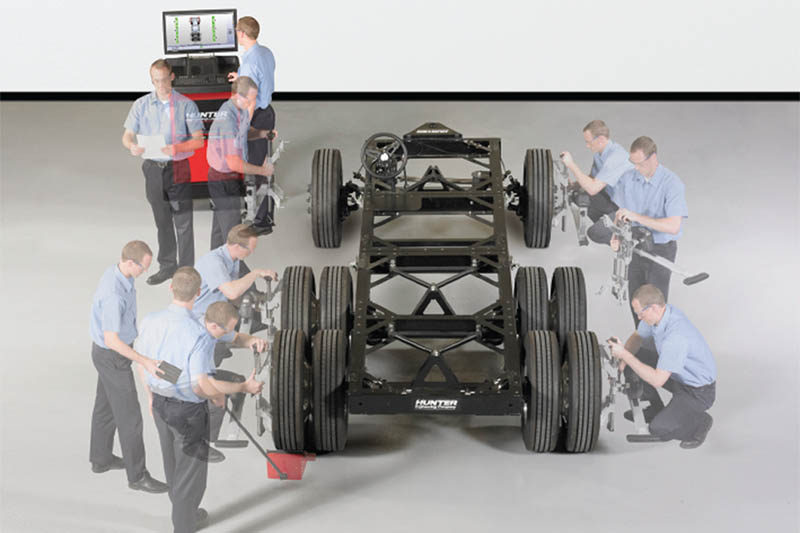

In order to deliver the time savings for workshops, Hunter’s engineers have designed an alignment system which removes many of the repetitive labour intensive steps that would normally be required.

For example, the Hunter procedure does not require any axles on the vehicle to be jacked. A simple roll forward compensation, which can be carried out effortlessly with the Hunter truck pusher, is all that’s required.

The number of walking steps required by technicians to perform the alignment and the number of sensor movements are also reduced significantly. In fact, Hunter’s engineers calculated that total steps taken by technicians to conduct an alignment check can be reduced from 203 to just 81 when switching to this system, greatly improving efficiency.

Furthermore, it’s not just the wireless Hunter hardware which contributes to the potential gains for workshops; the WinAlign HD software also plays an important role too. As well as having one of the most extensive vehicle information databases available, it also includes a wealth of adjustment videos and work management features which provides technicians with on-the-job assistance to improve their skills and effectiveness further.