Marc Haley, Director of Alliance Transport Technologies, the aftermarket solutions supplier for the commercial vehicle market, discusses how remanufacturing delivers a money- saving solution for fleet operators.

In an industry where downtime can be incredibly costly to a business, remanufactured parts can save fleet operators and commercial vehicle owners thousands of pounds. Rather than investing in a new part, many components can be remanufactured and restored back to working condition to provide the same reliability, but at a fraction of the cost of a new replacement.

Investing in new parts whenever a vehicle has a technical fault can be an expensive way to manage a fleet; remanufacturing can provide a quick, reliable and cost-effective alternative – saving customers up to 70% on costs.

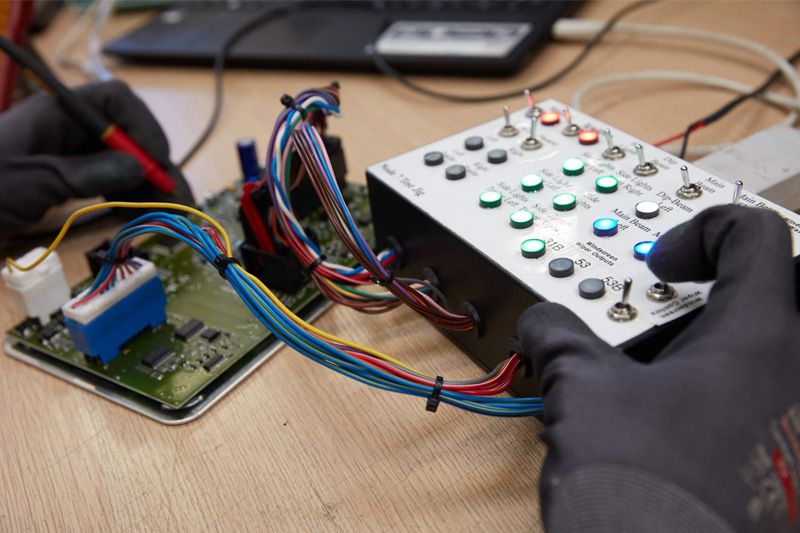

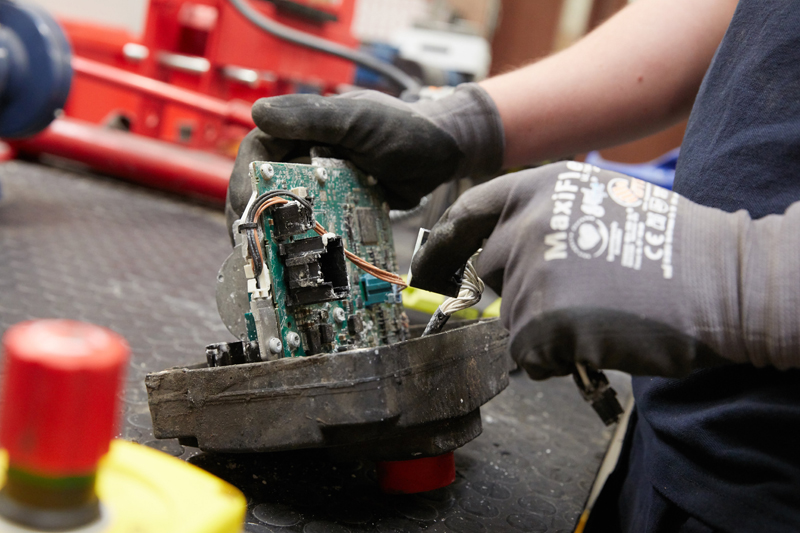

The remanufacturing process begins by disassembling a faulty component completely, and thoroughly cleaning it before an examination takes place to check for any damage or signs of wear. Any replacement accessories are added, before all the pieces are put back together for testing.

Once testing is underway and the part is back in full working condition, it is ready to be reinstalled. Generally, it takes less than eight hours to remanufacture a standard part. For example, a broken or faulty instrument cluster can be returned to a fleet operator on the same day and placed back in the dashboard. With fleet operators, time equals money, meaning these lead times can make a huge difference to a business that loses money the longer a vehicle is off the road.

Alongside the time benefits, remanufacturing is also better for the environment, as fewer raw materials are used and less energy is wasted compared to the production of a new part. There is also less waste, as the broken component is replaced in the vehicle, rather than adding to landfill, along with the packaging that a new part would arrive in.

A remanufacturing programme can also help a business reach its CSR agenda and assist in developing sustainable ways for your company to thrive in a more ethical way. This can reflect well on potential customers looking for more eco-friendly ways to outsource delivery services.

Alliance passes these benefits on to its customers, some of which are the top bus and coach groups in the UK, including Stagecoach, First, Go Ahead and Arriva.

Remanufacturing offers a valuable alternative to fleet owners and operators looking to invest in OE parts. The service provides customers with a saving of up to 70% when compared to the investment of a new replacement. For businesses operating large fleets, remanufacturing is a sustainable option, with all damaged or broken parts being restored to working condition, instead of being disposed of and replaced.