Ken Clark, Managing Director at Rotronics, discusses the company’s efforts to assist a rail and bus public transport operator with their battery servicing requirements.

Rotronics has been working with a UK rail and bus public transport operator in their London division to eliminate electrical non-starts with the introduction of a Battery Management Programme. An additional driver for the programme was to reduce costly battery replacements, which creates an expenditure of tens of thousands of pounds annually in the bus sector.

The Rotronics team has worked with management team and all technicians to help them understand the rationale behind the Battery Management Programme and the resulting benefits, so that they would use all aspects of the programme within every service. This has meant that their first-class customer offering was not compromised by sub-optimal standards due to battery-related problems.

Ken Clark comments: “We work closely with the team to help them understand that the fleet batteries must be kept above 12.4V at all times as this helps to ward off the problem of sulphation, which is the biggest battery killer. Keeping the 24V battery sets in balance is also vital and we discovered that most of the premature alternator issues were a result of unbalanced batteries.”

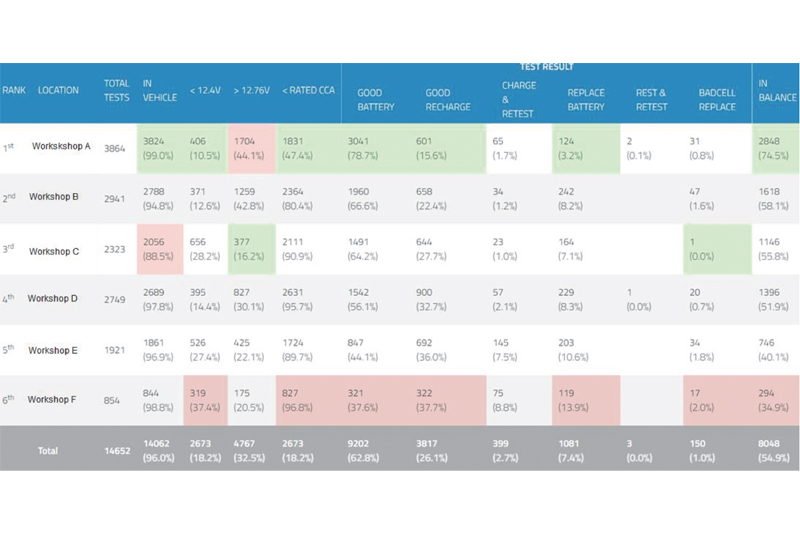

The above table highlights the overall battery performance from each of the six workshops, whereby they are ranked by the % of battery tests that have been tested both as “in balance” and “good condition”. We can clearly see that the workshop that is making the most improved advancement in battery conditioning and maintenance is workshop A, whereas Workshop F performance is considerably behind. What this tells us is that workshop A is more proactive in maintaining the fleet as part of a pro-active approach, with Workshop F, focussing on testing but not charging batteries that require attention.

The net impact will be seen in the longevity and reliability of workshop A vehicles being much more positive than that of Workshop F, that will see increased vehicle non-starts, and risk of increased premature failure.

Ken Clark continues: “It has been really important for us to develop a solution that fits into the existing maintenance programme, so that we didn’t cause disruption and any vehicle downtime. The new programme enables testing, diagnosis and charging of the battery and the electrical system. The team now use the Midtronics Charge Express Pro 50/2 unit, which conditions, charges and balances the batteries. For a belt and braces approach, we have developed a bespoke training module for the technicians, which has helped deliver the required cost saving and customer benefits and technician processes.

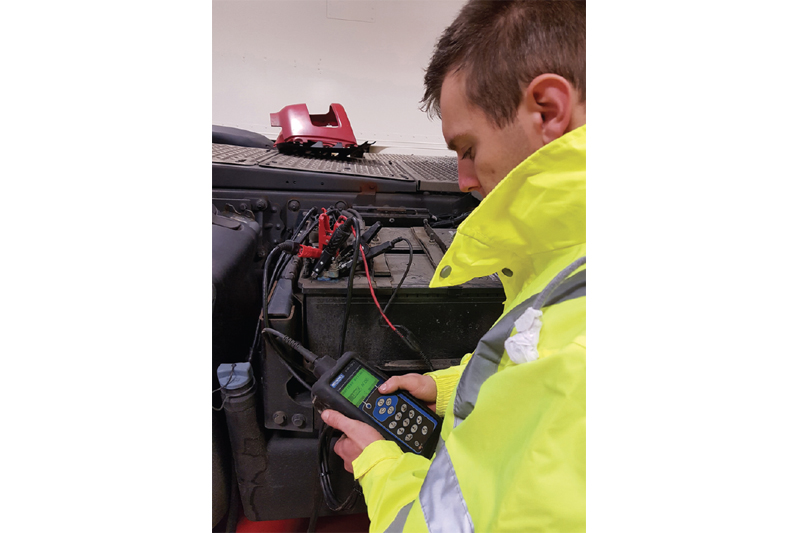

“Every vehicle arriving in the workshop is tested using the Midtronics EXP1000HD to check the battery’s condition. The tester can pair batteries and so if a faulty battery is found, only one needs to be replaced, thus saving considerable costs. Then the battery is connected to the Midtronics Pro 50/2 charger when other work is being carried out, and this will condition, charge and balance the battery set. It is also important to re-test at the end of the full service and record the charge levels on vehicle’s maintenance record.”

The EXP1000HD battery and electrical system tester is designed to perform a full system test in under a minute and a half. It is suitable for 12V and 24V Systems and battery technologies and can determine the condition of each battery. It can complete a starter and alternator test and all the data will be stored on an SD card for analysis.

The ChargeXpress Pro 50/2 has twin output, which allows 24V balanced charging, or can be used on separate 12V systems at the same time. It is suitable for all battery types and has 5m heavy duty detachable charging cables, with spike protection.

Rotronics has also been working closely with a UK-based haulage fleet which has over 600 haulage vehicles in the express freight, logistics and warehousing sector. The haulage fleet’s management team contacted Rotronics to help solve their battery management problems prior to considerable expansion plans. In addition, they wanted to reduce battery defects and increase distribution productivity using a battery management programme of regular testing and charging.

Some help was also required to resolve warranty issues due to limited battery management data, and the fleet managers were finding battery defects on brand new vehicles. Without battery data to back up any claims, the haulage team was struggling to provide backup data for warranty claims and this meant increased costs in their battery replacement budget.

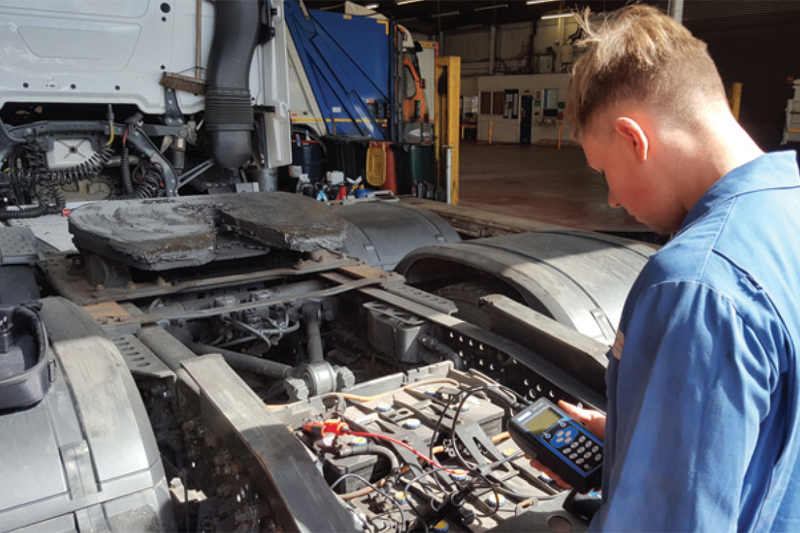

The Rotronics technicians carried out product demonstrations to help find the best solutions for the fleet, they worked through a bespoke battery management programme, including one Midtronics EXP1000FHD tester, one Midtronics PRO 50/2 charger, and a year’s subscription to ROBIS, the Rotronics remote battery management platform.

Ken Clark says: “The technicians wanted to be able to record VIN and fleet numbers and so the EXP1000FHD was chosen, to be used in conjunction with ROBIS, which provides workshop managers with live battery data as backup for warranty claims. The Midtronics PRO 50/2 charger was also selected because of its ability to combine charge acceptance and battery conditioning for 12V and 24V fleet batteries.”

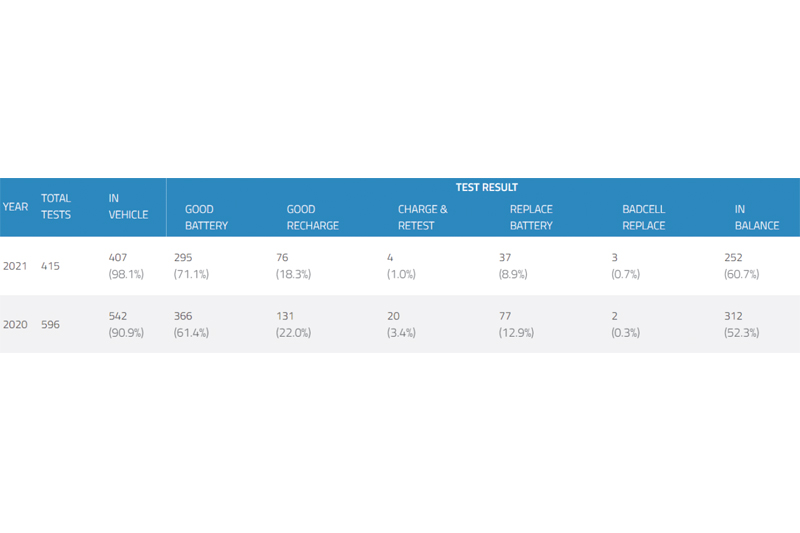

The above tables show the marked improvement of battery performance of the workshops fleet of vehicles over a two-year period. We can see a 10% increase in “good” battery results, along with an 8% increase in the number of batteries that are now “in balance”.

The net impact is a more reliable fleet, and a reduction in batteries requiring replacement in 2021. 40 additional units were replaced in 2020, with only 37 replacements in 2021.