Technicians need to be sure they are fitting OE quality wheel bearings, such as from the FAG range, says Schaeffler.

It shouldn’t come as a shock to know that wheel bearings are one of the most safety critical components fitted to any modern motor vehicle driving on the road today. When you take into account the extra weight, payload and cost involved in heavy commercial vehicles, it becomes even more important to ensure that the hub bearings you install are of a quality that cannot be compromised.

Schaeffler’s FAG RIU (Repair Insert Unit) range has grown from strength to strength in the CV aftermarket scene since it was introduced a few years ago. Unfortunately, there are examples where generic ‘will-fit’ parts are used instead, which don’t provide the same high quality standards.

Devil is in the detail

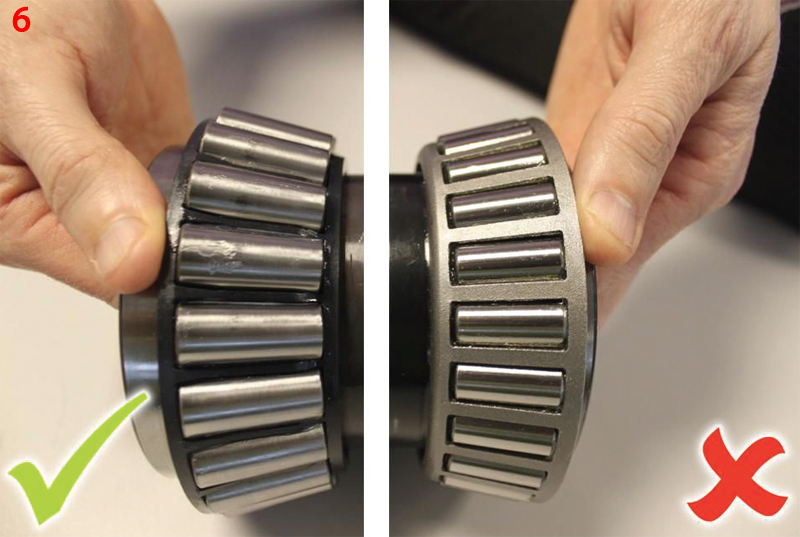

Would you say you have a keen eye for details? Look at the two bearings in Fig. 1 – can you tell the difference? It may surprise you to learn that even though they are sold to fit the same application, only one of them matches the material and manufacturing quality standards of the original equipment. Let’s take a look into the differences more closely, including the reasons as to why they are so different.

As a technical partner and OE supplier to the world’s leading vehicle producers, FAG must maintain the highest possible standards to ensure that our components are suitable for original fitment. We constantly and rigorously check and test our components during every stage of the manufacturing process to ensure that these standards are maintained. We also regularly check competitor’s parts to make sure we remain number one for quality.

This engineering comparison concerns FAG RIU reference 566074.H195 (fitted to DAF 7.5t.), and one of the will-fit alternative versions available in the aftermarket, to test and assess the differences between the two theoretically ‘comparable’ components.

As you can see from the images, there are some more obvious visual differences. The FAG version is supplied with a press fitment cap to prevent damage to the bearing during installation, with plastic grease protectors covering the bearing to ensure that grease does not escape or become contaminated (Fig. 2). The alternative version does not have either of these features, leaving the grease exposed which will greatly increase the risk of contamination.

Material testing of the other bearing also reveals some interesting facts. It shows considerable metal content variations, especially on the inner race, which will have a negative effect on resistance and bearing life expectancy. The rollers inside the bearing are constructed from a poor quality metal that is not suitable for wheel bearing application. Compared with the OE specification, there is also insufficient roller and raceway profiles, which together with a deficient geometry of the inner ring lip, will ultimately lead to premature failure.

What to consider

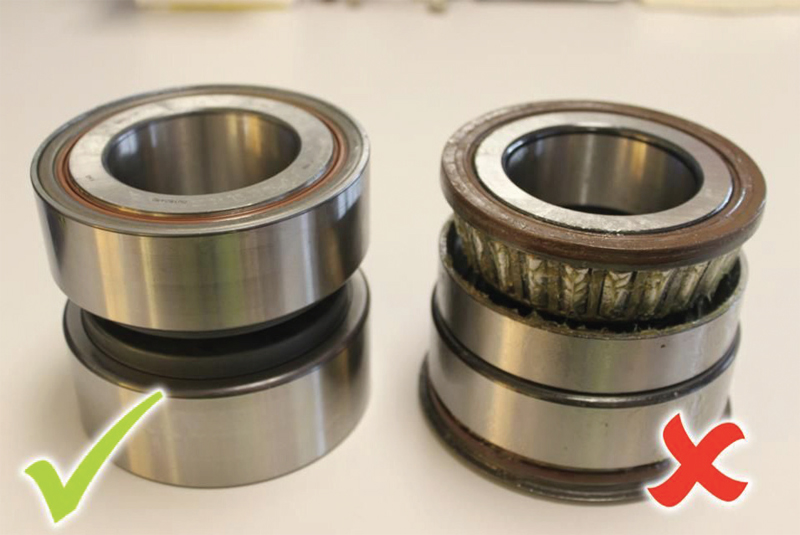

Preventing contamination (Fig. 3) is the most important factor to remember when installing a new bearing, because the undisputed number one cause of premature bearing failure is contaminated grease.

And the problems don’t end there – the grease used in the alternative bearing (Fig.4) only provided sufficient lubrication up to 185°C during testing, which is a huge problem when you consider that vehicles with disc brakes will easily exceed this temperature under normal braking conditions!

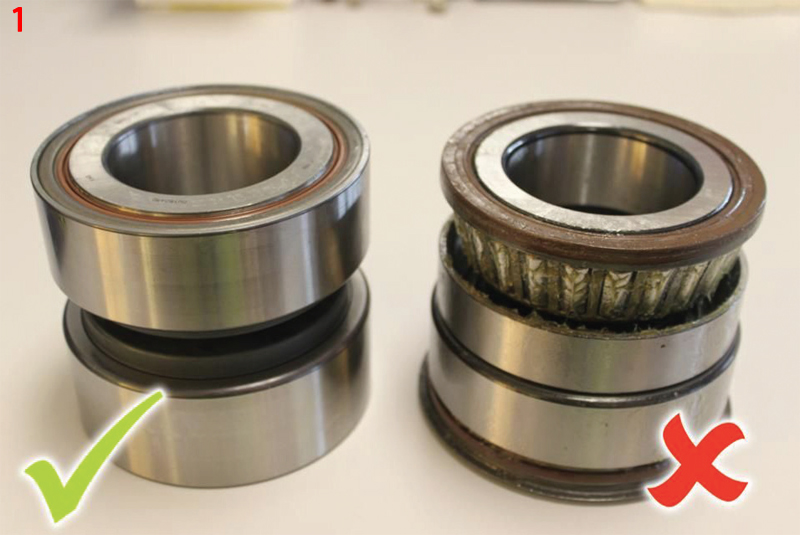

At this point the bearing would have ineffective lubrication, causing rapidly accelerated rapid wear and complete bearing failure. Opening the bearings reveals even more differences. The most obvious to spot is that the size of the rollers in the FAG bearing are much larger in comparison to the other (Fig. 5).

This allows the FAG bearing to withstand much more weight and pressure. Look at the comparison for yourself in the pictures, which one would you rather fit? (Fig. 6&7)