Tyre and wheel servicing is a crucial element of the work managed by commercial vehicle workshops, which is why it’s vital that operators have the right tools. Philip Brodey, Marketing Director at Norbar Torque Tools, sets out some of the key things to look for in a torque wrench and why it’s so important to get the right product for the job.

Size matters

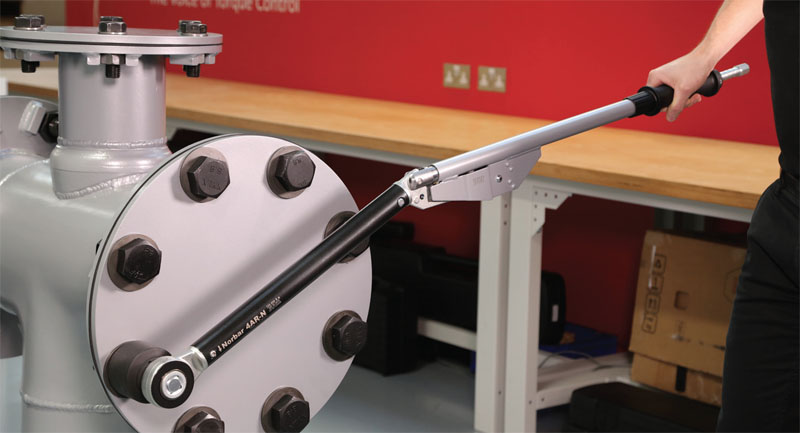

When working in a commercial vehicle workshop, or as part of an emergency callout team, availability of tools is paramount in order to get the job done. However, when space is limited, there’s a risk that users may have to leave crucial bits of kit behind, simply because it doesn’t fit in the van or cab. With this in mind, Norbar Torque Tools has recently launched the new generation Industrial torque wrench, featuring a split design to enable easy transportation and storage. With case dimensions of 970 x 260 x 95mm, it is largely portable and can be easily stored behind the seat of a lorry. Another benefit of having a smaller case is the more economic freight rates that can be taken advantage of when returning the tool for the recommended recalibration.

Clear signal

Of course, when working on the side of a road, in a busy workshop or in particularly noisy environments, a wrench’s traditional ‘click’ signal may not be heard, which is why a clear and visible torque signal is key.

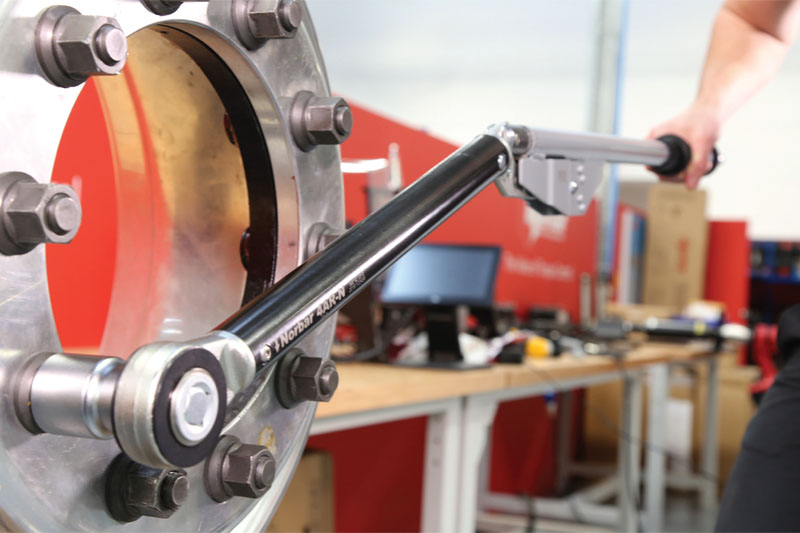

The new generation Industrial torque wrench caters for this requirement by featuring a unique profiled cam and reaction plate, which gives an unmistakable, visible torque signal, whilst the large break angle greatly reduces the possibility of overtorquing.

One click is enough

When nuts are attached to the wheel bolts or studs, the bolts stretch as the nut is tightened. By clicking a torque wrench more than once, users apply extra load and exceed the set torque, which further stretches the bolt above and beyond its optimum capacity. This brings the bolt closer to its yield point which can ultimately lead to bolt failure. Because of this, Norbar encourages users to follow its ‘one click is enough’ rule.

Safety critical task

Ensuring the wheel bolts and studs are correctly tightened on any commercial vehicle is a safety critical job. A wheel detaching from a moving vehicle could cause a driver to lose control, as well as the runaway wheel presenting a serious safety hazard to other road users or pedestrians.

What is often overlooked is the fact that a nut can just as easily be too tight as it can be too loose, and both pose significant safety risks. This issue can be addressed upon the selection of a new wrench, whereby the user should choose a tool that includes safety benefits such as a large break-back – a key feature of the Industrial torque wrench.

Simple setting

The Industrial wrench also includes a much clearer and easier to read scale; relocated within the handle. Protected by a lens to make it more resistant to dirt, dust, and oil spray, the features contribute to the improved robustness of the tool.

The company also claims that if an area of the lens becomes scuffed, the design of the wrench allows it to be rotated so an unmarked portion of lens can be moved over the scale. When the entire lens has been used, it is simple and relatively cheap to replace it without disturbing the calibration.

Accurate and robust

Accurate to ±4% even in arduous conditions, the wrench also features a push-through ratchet to enable torqueing in a clockwise and anti-clockwise direction, and an adjusting spanner, so there is no requirement for an additional tool for torque setting.

Presenting a total range of 120 to 1,000N·m, the new generation further enhances the Industrial torque wrench’s reputation for being robust and simple to use.

Users must always remember that it is essential to check the correct torque for wheel nuts in the vehicle manufacturer’s handbook. Crucially, best practice standards within a workshop cannot prevent driver error on the road or general accidents, but they can certainly help to reduce risk – a fact that should not be taken lightly.