Darren Stevens, Technical Sales Engineer for Knorr-Bremse, provides some helpful tips for diagnosing the company’s trailer electronic brake systems.

Knorr-Bremse introduced its first generation of Trailer Electronic Braking Systems (TEBS) in 2001. Known as TEBS 4 ECU, it became a mainstay for trailer manufacturers for the following seven years. After this, the second generation (TEBS G2) was introduced in 2008, followed by the release of TEBS G2.1 and TEBS G2.2 over the next five years.

Here are some useful tips for fleet workshops running Knorr-Bremse TEBS trailer systems:

What happens if your trailer warning lamp is active?

Have you tried another tractor unit? We often find trailer faults are caused by bad power supplies. Trying another tractor unit/towing vehicle is an easy way to diagnose simple power issues.

Does your trailer have a TIM (Trailer Information Module) fitted? Usually mounted on the left-hand rear corner of the trailer chassis, the TIM module gives you direct access to the active and stored fault messages in our TEBS ECU.

If your trailer is still covered by the manufacturer’s warranty scheme, the trailer manufacturer should be contacted in the first instance. For older trailers, one of our 80 UK approved Knorr-Bremse Service Centres can help. Details of these can be sourced from our Knorr-Bremse Technical Team.

We can also supply further advice/information on our trailer systems, by phone: 0117 9846222, or via email: technical@knorr-bremse.com

Knorr-Bremse ECUtalk (PC-based) trailer diagnostics

For further diagnosis of our trailer systems, special diagnostic software is necessary. Knorr-Bremse’s ‘ECUtalk for TEBS4 or TEBSG2’ can be used in conjunction with our Trailer Diagnostic Connection Kit (part number KB915).

Trailer diagnosis can be carried out via a suitable laptop. PIN numbers are needed to work on the TEBS systems and to enable the replacement of an ECU with full traceability and safety. These PINs can be purchased via the Knorr-Bremse website. One number is required for TEBS4, and one number for TEBSG2. Purchasing the PINs entitles the owner to on-site training.

Knorr Bremse ‘ECUtalk’ software downloads and software PIN number applications can be carried out via the website, www.knorr-bremseCVS.com

Diagnostic developments

As part of its improvements to vehicle safety and productivity, we are launching three new systems for use on all types of trailer. These devices are designed to offer significant operational benefits to fleets, both in terms of practicality and reducing costs.

The products are:

1. iTAP (Trailer Access Point)

2. iLVL (Trailer Suspension Control)

3.TPMS (Tyre Pressure Monitoring)

For more information on any of these products contact Knorr-Bremse technical services on 0117 9846222 or email technical@knorr-bremse.com

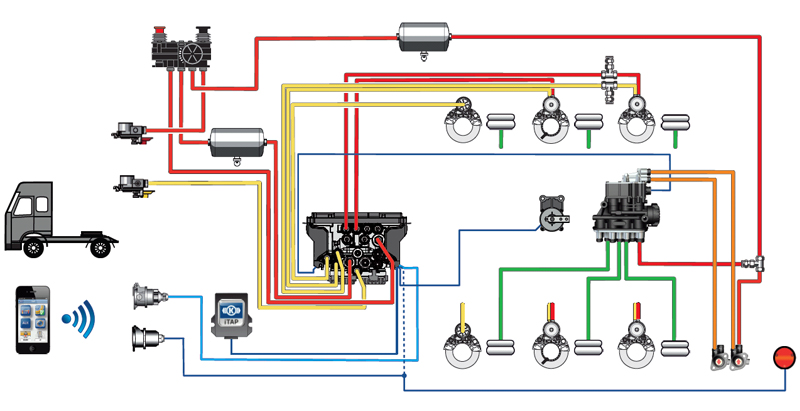

iTAP (Trailer Access Point)

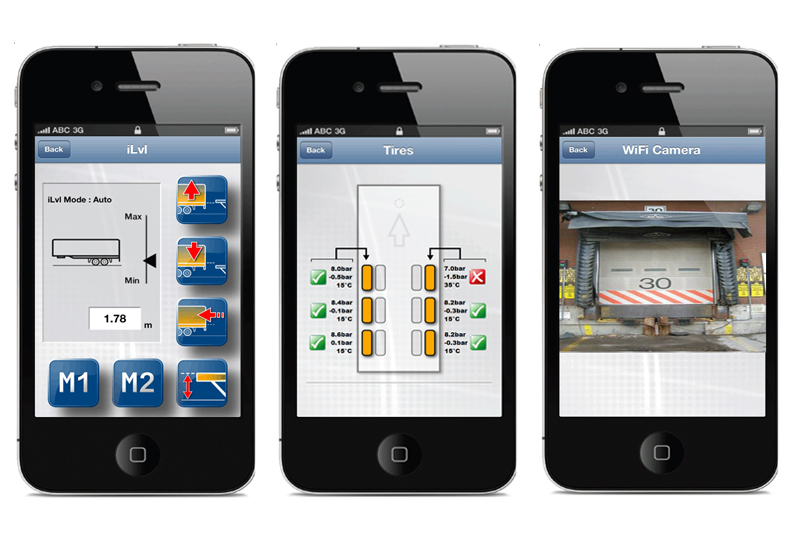

Trailer Access Point (iTAP) equips the trailer with a secure Wi-Fi connection. This means that from the comfort of the vehicle cab, the driver can access any number of trailer functions to interrogate them for information, and also to interact directly with them. This eliminates the need for bespoke wiring between truck and trailer, and also reduces the need for the driver to climb out of the cab to operate buttons and levers etc. Clearly, this has major health and safety benefits. Using a tablet or smartphone, the driver can control lift axles, suspension height (iLVL), steering axles, tyre pressures and temperatures, bogie weight, air pressures, and fault information. The iTAP is powered directly by and communicates with the trailer EBS.

Future developments for the iTAP will include a wireless reversing camera.

iLVL (Trailer Suspension Control)

We often receive requests from our customers for suspension controls, which are outside of the normal set-up. In addition to manually raising and lowering, we are asked for alternate ride heights, dock heights, and other ways for the driver to control the system. To this end, Knorr-Bremse is now offering the iLVL suspension control system.

The system replaces standard level valves and raise/lower valves with a level sensor and control buttons. These allow the system to monitor and control trailer height, as well as allowing manual control. Such control allows the trailer to be set with several selectable ride and dock heights, as well as a high speed ride height or improved aerodynamics and stability. The driver can interact with the system via the buttons (multiple sets are possible), TIM (Trailer Information Module), or iTAP.

TPMS (Tyre Pressure Monitoring System)

How much do tyre failures cost your operation? Keep in mind that it’s not just the tyre failure, but also damage to the trailer, late delivery and of course, the serious health and safety implications of a failure on the highway.

Knorr-Bremse TPMS uses sensors mounted inside the tyre to measure the pressure to ensure correct inflation of the tyre. The internal temperature is also monitored, which can warn of not only potential tyre failure, but also dragging brakes, bearing failures, or other possible causes of trailer fires. This data is then collected and transmitted via iTAP, TIM, Vehicle dash (if compatible), or a warning light.