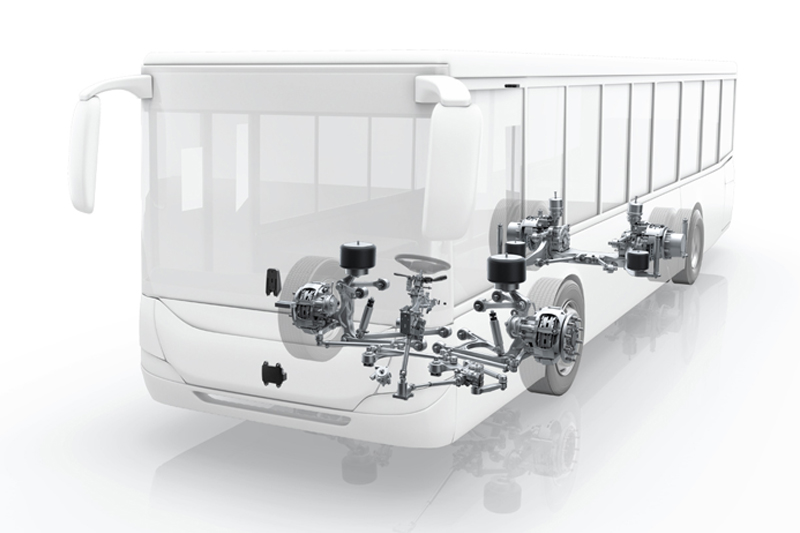

ZF Services recently launched its latest design for electric drivetrains, the AxTrax AVE electric portal axle for city buses with a gross vehicle mass (GVW) of up to 29 tonnes. Simon Ackroyd, Product Support Engineer at ZF Services UK, explains the technology involved and the benefits this transition to electrification is set to bring.

Q. What do you feel the benefits are to the new AxTrax AVE electric axle?

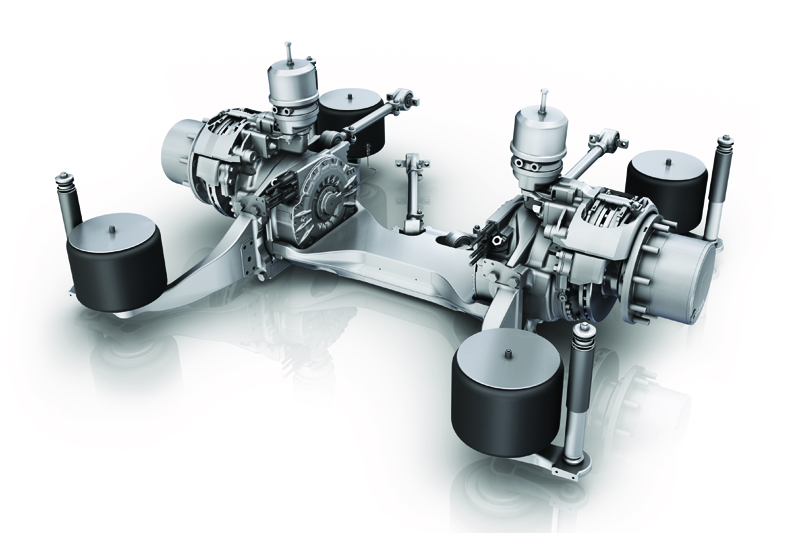

Simon Ackroyd (SA): The AxTrax AVE is one way of contributing to electro mobility in urban areas. The propulsion system is designed for city buses with a maximum axle load of 13,000kg. An electric motor is installed close to each wheel in the portal axle, and each has an output of 125kW/170HP and a torque of 485Nm, with speeds of up to 11,000 revolutions per minute.

Due to its ‘speed-induced high output’, this electric motor was designed with smaller dimensions, and therefore offers benefits when it comes to integration. Since the electric motor is highly integrated into the wheel head of the axle, interfaces identical to those of a conventional drive axle can be realised. This enables the axle suspension parts to be shared, including the control arms and spring carriers, as well as air springs and shock absorbers. The axle’s mechanical connections in the vehicle design are identical. This produces synergy effects.

Moreover, the engines mounted on the rear axle are designed for low-floor installation, which creates space inside the bus. This enables the rear rows of seats to be installed individually, regardless of where the drive units are located in the vehicle. Also, this concept means that the bus is completely accessible from the rear, which in turn opens up more freedom and further possibilities for vehicle designers to apply their innovation – a must for future high- capacity city bus passenger comfort and flow.

In addition to more space, this solution also reduces the weight of the bus. The entire axle unit with electric motors, control arms, springs and shock absorbers weighs a mere 1,220kg, a weight reduction of 200kg. In other words, 200kg less that has to be moved, which saves energy that can be converted into a greater drive range.

Just as valuable is the portal axle’s versatility. The axle is, in principle, compatible with all drive concepts, so it can function as a hybrid together with a fuel cell, a battery, or an overhead line.

Q. How has legislation led to the design of the technology?

SA: By 2050, the UK is bound to cut its greenhouse gas emissions by 80% in accordance with the 2008 Climate Change Act. In 2007, the government commissioned the King Review of low-carbon cars. This review concluded that, in addition to other low-carbon technologies and behaviour change, electric vehicles (EVs) would be necessary to achieve an 80% reduction in transport emissions.

In addition to widespread EV uptake, the proportion of electricity generated from low-carbon sources would need to increase significantly to meet this target. EVs are not expected to make a major contribution to emissions reduction until after 2020.

However, the review argued that the market for low-carbon vehicles needs to be developed now in order to meet long-term emissions reduction targets. In 2004, this worldwide movement had already been recognised within ZF, and so the starting signal for further development of the existing EE-Drive electric axle technology began.

Q. Are there any key points that technicians need to be aware of when retrofitting/repairing?

SA: As this axle is subject to high voltage regulation, anyone working on these products must be certified. Within ZF, we have intensive training and a requirement to have our abilities assessed every 24 months.

Q. How has the technology been received?

SA: We are finding that operators are relieved that our product is readily available for them to meet this new legislation, with new vehicles and the opportunity to up- cycle existing fleets part-way through their lifecycle a real possibility. The fears of heavy maintenance and running costs are being eroded, and operators are now welcoming this new technology.

Several road tests were carried out with various operators in a vehicle fitted with AxTrax AVE. The technology was received exceptionally well, both in performance and the add-on benefits of less weight, reduced noise emissions, increased passenger capacity, etc.

Q. Where will we start to see the AxTrax AVE?

SA: The location of such technology will of course be determined by local governments and legislation. For example, London, with its technological advancement, is usually the first city that many think of. However, around the UK, other cities are pushing forward with emission-free zones, which will drive the electric vehicle production and operation.

Q. Does the introduction of this technology signify the direction in which bus technology is developing?

SA: Technology across all industries will be directed towards cleaner, greener solutions. Ultimately, this is the core value of ZF’s ‘Vision Zero’.

Taking it for a test drive

Recently, members of the Northern Regional Engineers Committee (NREC) met at ZF Services UK’s Centre of Competence in Nottingham. Delegates were invited to board a ZF Test bus, specially fitted with the ZF AxTrax AVE electric axle, as they were taken on a test drive around Nottingham city centre.

The 45 minute showcase enabled the group to experience first-hand the benefits of the electric axle – specifically the take-off, the noise reduction, and the uncompromising and relentless torque delivery, all achieved with zero emissions and self-charging technology.

Mick Forbes, Engineering Director of Stagecoach East Midlands, said, “The visit was very well executed by ZF Services UK and the test drive was an extremely effective way of proving to its customers the competence of its e- mobility portfolio.”

Other positive comments were received from the group, including Jon Eardley, Engineering Director at Abellio, “It’s provided us with invaluable insight and we’re genuinely excited to see how future transport will shape up with ZF’s leading driveline and chassis technology through the AxTrax AVE.”