Bosch guides CVW through the handling of Lambda sensors, from diagnosis to safety.

All engine functions, from mixture formation to exhaust-gas treatment, need access to the latest highly accurate data from the exhaust gas system. Mixture formation, which is controlled by the engine control unit, has an influence on the pollutant content of the raw exhaust gas. The LSU 4.9 wideband Lambda sensor precisely determines the residual oxygen content in the exhaust gas and thus helps to ensure that compliance with current and future emission and OBD regulations is maintained.

The LSU 4.9 is used in commercial vehicles with a 24V electrical system. Its robust sensor element design ensures it is particularly durable. It furthermore has a high thermal stability. The sensor is built for continuous operation at ≤ 930°C and can handle peak temperatures in the exhaust gas system of ≤ 1030°C.

Despite its high durability, though, a Lambda sensor is still a wearing part. Contaminated fuels and oil residues formed during combustion can leave traces over time and shorten the sensor’s service life. Regular inspection and replacement, therefore, make economic sense. After all, only Lambda sensors that do their job properly can be relied upon to help keep the engine functioning as it should.

Lambda sensor diagnosis in three steps:

1. Read out fault memory and check actual values

2.Check signal patterns (as per ESI[tronic] 2.0)

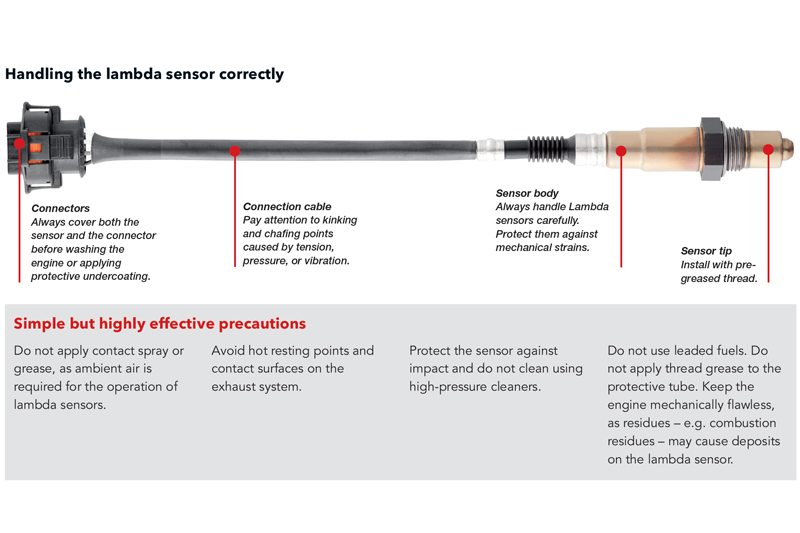

3. Check cables and connectors for good contact