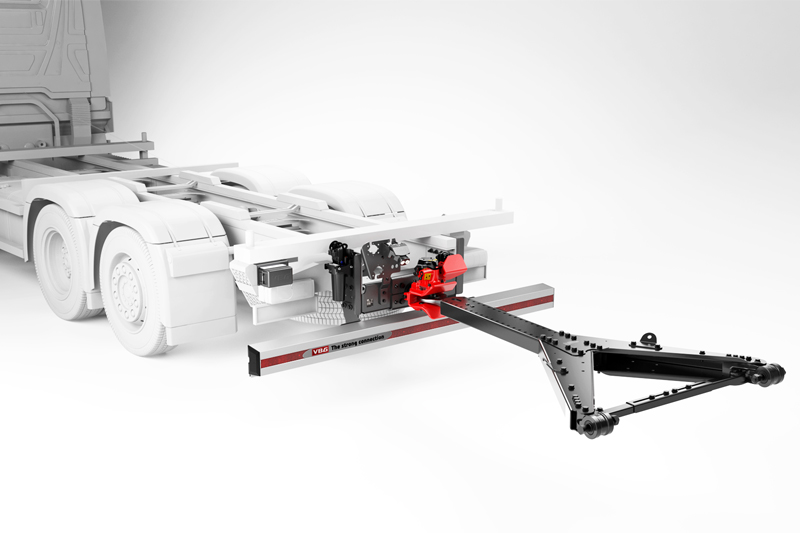

The grey area between servicing truck and trailer can lead to crucial safety components being neglected. Truck trailer manufacturer, VBG Group, offers advice on the maintenance of drawbars and ensuring the safety of your fleets.

Drawbars are now becoming increasingly popular in many road haulage operations, from regular bulk distribution to more unusual applications such as road sweepers and liquid waste tankers. The common factor with all drawbar combinations is that they require regular servicing and inspection, which should be incorporated within the vehicles own maintenance program.

Frequently, VBG hear the comment from the service provider, “We only service the truck, the coupling isn’t our responsibility”. This argument won’t stand up in court if there is an accident as a result of a coupling failure and subsequent detachment of the trailer. Someone, usually the truck operator, is responsible for this equipment. The coupling equipment should be treated as safety critical and be maintained and inspected at regular intervals.

If the vehicle is covered by a manufacturers repair and maintenance contract then the onus is on the operator to ensure that the coupling equipment is covered within the contract. If not, then it should be treated as a separate item and records kept of inspections and repairs etc.

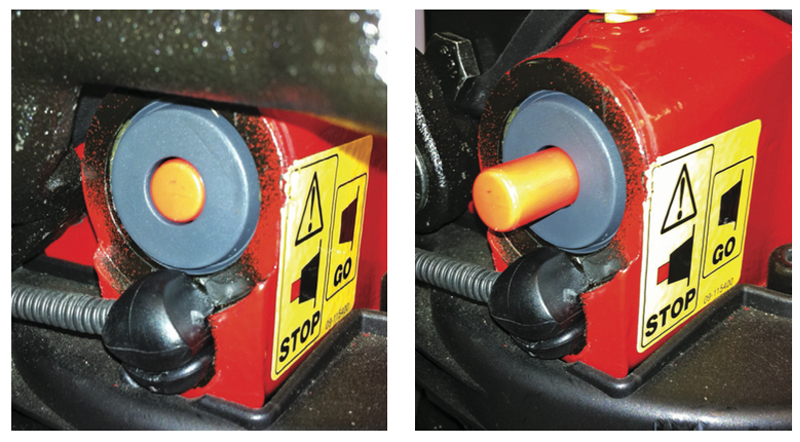

The service checks should cover the function, security, wear and damage. Items such as the chassis mounting side plates and draw beam (towing cross member) also need to be included. Safety critical items, such as the lock indicator button, should be undamaged and move freely within its housing. This unit must work correctly at all times, and if found to malfunction should be defected and considered not safe to use.

Correct and regular lubrication of the coupling is crucial to its operation and VBG Mec Oil, an aerosol spray lubricant, is recommended by VBG Group. This should be applied regularly through the lubrication holes in the mechanism lid, secondary lock and lower jaw bushing areas. Do not use grease, for obvious reasons, as it will simply act like a magnet for road grit. The road grit can also cause premature wear resulting in a failure of the moving parts to lubricate within the mechanism.

Another part of the truck/trailer connection that needs to be inspected is the trailer eye. Obvious checks are wear, straightness and security.

Driver Training

Driver training is of paramount importance to ensuring safe operation. Simply assuming that the driver has the necessary license to drive a drawbar outfit is not good enough. It is necessary to ensure that the driver is properly instructed and fully understands the correct coupling procedure and knows how to check and, when necessary, defect the coupling.

VBG group strongly recommends drivers are aware of the proper safety procedures. The company says that, left to their own devices, drivers will come up with their own ideas on what checks they make to ensure that the coupling is closed and locked.

The following examples are typical replies from drivers when asked how they know if the trailer is safely coupled.

- The handle, some times referred to as the ‘flag’, is down

- I do a pull (tug) test

- I listen for the coupling to click twice

- I stick my finger up through the bottom of the coupling to feel the pin is through

All of the above are wrong, they do not indicate that the coupling is safely locked. The only safe and correct check is the lock indicator button, which in the safe/locked position will be flush with its housing.

Simply put, if the button is projecting at all from its housing, the coupling is neither locked nor safe to use.

Where the air assisted opening/closure option is fitted to the coupling, it is important to ensure that the driver knows how to correctly operate the control levers. The valve box lid will only close when the levers are in the correct safe travel positions.