In the second instalment of this two-part series, Norbar Torque Tools’ Philip Brodey lays out the final five tips for torque wrench best practice.

1. USING MARKED LOADING POINTS FOR ACCURACY

Most torque wrenches are length- dependent and feature a marked loading point on the handle, but many people don’t use it. For accurate results, most torque wrenches have to be operated with your hand centred over the marked load point. It is also essential that this load point is observed when it comes to calibrating the torque wrench.

2. LOOSENING WITH TORQUE WRENCHES

So long as users operate with caution and do not exceed the maximum torque, most torque wrenches can be used for loosening. However, if the bolt will not free within the maximum torque of the wrench, another tool should be used instead. By exceeding the maximum torque limit during a bolt loosening, you can affect the wrench accuracy, causing problems for future use. If in any doubt, use another tool for loosening bolts.

3. ADDING EXTENSIONS TO THE HANDLE

Users should never put a pipe or any other kind of extension onto a torque wrench handle as this can seriously damage the tool and make it inaccurate – never mind the potential safety hazard.

4. LOCKING IT IN

It can be all too easy to accidentally adjust the settings of a wrench during use, so if your torque wrench is fitted with an adjustment lock, you should always apply it before operating the wrench in order to avoid any unintended changes.

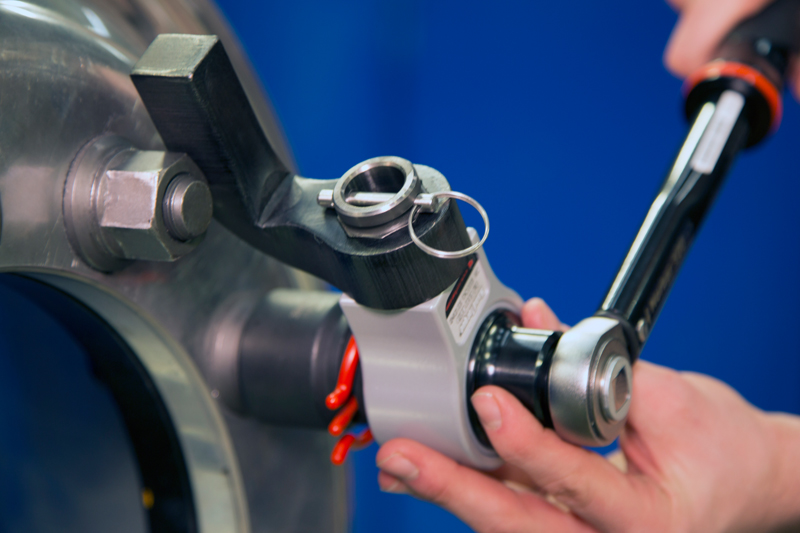

5. APPLYING ‘CROW’S FOOT’ TYPE FITTINGS

‘Crow’s foot’ type fittings can be applied to a torque wrench square drive, but they will alter the torque. It is therefore important to apply a suitable offset to the set torque. For guidance with setting offsets, users can download Norbar’s Torque Extension App for IOS and Android.

Keeping this advice in mind will see users getting more from their tool, with the wrenches remaining accurate and lasting longer. The tips are simple, but the implementation of these basic rules can often be forgotten, and that’s when mistakes can happen.

We hope that users will see the benefit of the advice provided in this two-part series, take on board the comments, and apply them to ensure accurate results and the safety of applications.