The critical role of torque control in maintenance

Chris Bull, applications specialist, Norbar Torque Tools, looks at the critical role of torque control in vehicle maintenance and how precision must be embraced for performance and safety.

With automotive maintenance and repair, precision isn’t a luxury: it’s a necessity. And one key element where acknowledging the need for precision is essential lies in torque control, a fundamental aspect that goes beyond merely tightening nuts and bolts.

Effective torque control ensures that every component of a vehicle is assembled to the exact specifications required for optimal performance and safety. With the advent of digital torque wrenches equipped with data collection capabilities, the industry is witnessing a revolution in how maintenance tasks are performed, enhancing both reliability and traceability.

Understanding torque

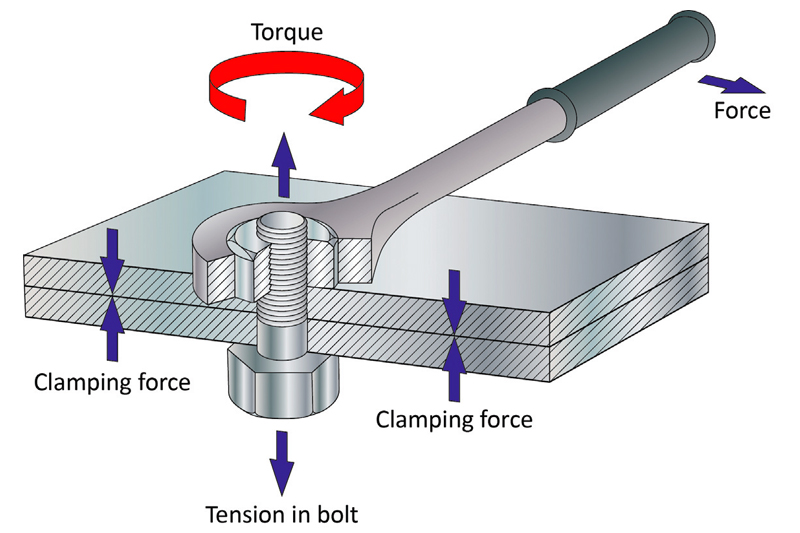

Torque, in simple terms, is any force or system of forces that tends to cause a rotation about an axis. For vehicles, proper torque application is crucial as it affects everything from the wheels to the engine. Incorrect torque can lead to a host of problems, such as parts that are too loose and fail to perform as intended or too tight, causing undue stress and premature wear. Therefore, the precision in torque application cannot be overstated.

From analogue to digital

Historically, torque wrenches were mostly analogue, requiring a keen sense and experience to gauge the correct torque. However, digital advancements have led to the development of torque wrenches that not only provide precise measurements but also offer data collection capabilities. These modern tools have transformed maintenance practices by ensuring accuracy and providing feedback that can be analysed to improve safety, procedures and training.

Digital torque wrenches represent a significant leap forward. They allow technicians to apply exact torque settings, reducing the risk of human error. The realtime data collection feature provides a digital footprint for each action, creating an invaluable record for quality control and accountability. This aspect is especially critical in scenarios where maintaining and proving compliance with safety standards and specifications are required.

Business benefits

Incorporating digital torque wrenches into vehicle maintenance routines offers numerous benefits for businesses. These tools not only enhance the quality and reliability of work but also elevate the business’s credibility. The data collected serves as evidence of due diligence and adherence to best practices, which is essential for building trust with customers. Moreover, the ability to track and analyse maintenance actions opens avenues for continuous improvement, potentially reducing the occurrence of costly errors and rework.

More than just compliance

Traceability provided by these digital tools goes beyond mere compliance. It’s about creating a culture of transparency and excellence. Having detailed records of maintenance activities can be invaluable during audits, warranty claims, or when diagnosing recurring issues. This level of detail ensures that businesses can stand behind their work with confidence, knowing that they have the data to support their practices.

As the automotive industry continues to evolve, embracing technologies that enhance precision in maintenance tasks will become increasingly important. Digital torque wrenches with data collection capabilities are at the forefront of this change, offering a blend of accuracy, efficiency, and traceability. Workshops that adopt these tools not only set themselves apart in terms of quality and reliability but also demonstrate a commitment to safety.

The integration of precise torque control into vehicle maintenance is not just about following best practices; it’s about setting new standards. As we move forward, the tools we use not only define our work, but also the trust and reliability that customers place in us. In an era where every detail matters, precision is the key to unlocking superior performance and safety.