The features of solid and vented brake discs

CV brake specialist Fras-Le discusses the merits of solid and vented discs, how both perform and where they are best suited.

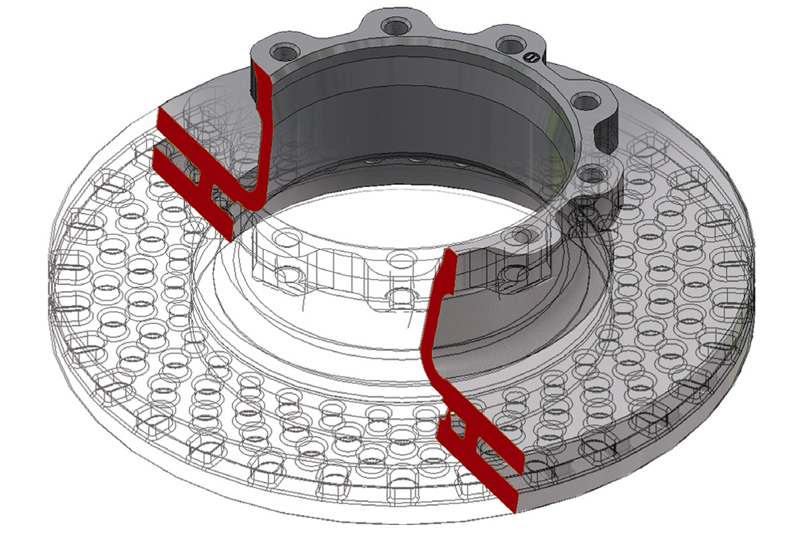

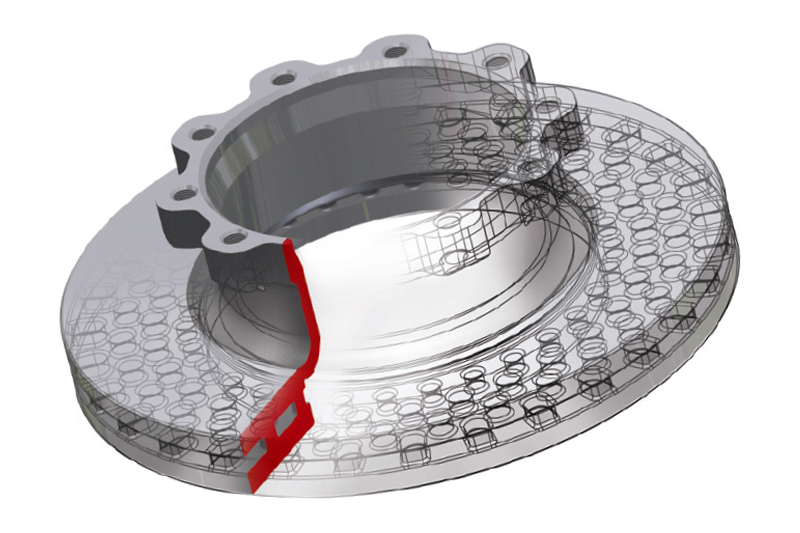

Solid discs have their place, on off-road and quarry applications, for example where mud, sludge etc can fill the vents. This can lead to reduced effectiveness, but for on-road applications vented discs are generally a superior choice – if they weren’t vehicle manufacturers wouldn’t fit them as OE.

Vented discs cool up to 40% faster than solid discs, so other components such as rubber seals, tyres and bearings around the brake set up are exposed to high temperatures for less time, providing longer life and better safety.

Don’t fade away

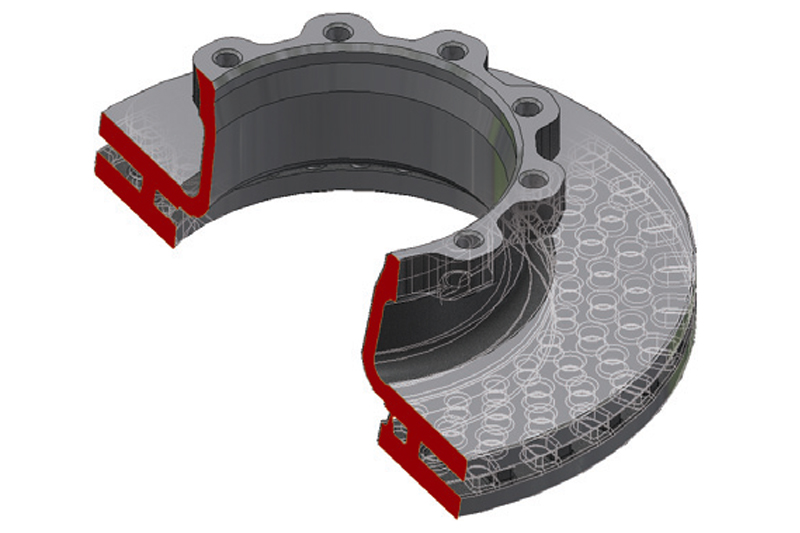

Vented discs weigh less than an equivalent solid disc by seven kilograms which amounts to 14kg per axle. Extra weight reduces payload carrying capacity and increases fuel consumption, and because of the extra mass, solid discs are also much more expensive than the equivalent vented rotor by at least 30%. As it has a much bigger mass, a solid disc acts as a much bigger heat sink, so on a single stop the temperature rise during braking will be less with a solid disc than a vented disc.

Some suppliers claim that solid discs do not increase brake fade; this cannot be true when repeated brake stops are carried out. As previously explained, vented discs are designed to cool significantly quicker than solid discs, therefore over a series of repeated stops, a vented brake will be less prone to brake fade.

For example if the temperature after braking has reached 300° C then 10 seconds later the temperature of a ventilated disc will drop to say 250° C. Whereas a solid disc will have only dropped to say 290°C. Therefore, when the brakes are applied again the temperature of solid discs is higher and therefore more likely to suffer brake fade on subsequent stops.

Due to their mass solid discs may also be less prone to distortion when hot but generally this is not an issue with properly designed vented rotors and thermal “hot spotting”. Plus, crazing and cracking is as much to do with the composition of the cast iron, the choice of friction material and how well it conforms with the disc to ensure uniform pad/disc contact.

Fras-Le vented brake discs are R90 compliant. Some competitors have used the UNECE R90:02 thermal fatigue test to compare Scania vented and solid disc; the solid disc comfortably passes the test, but the vented disc fails, only completing seven of the 15 cycles required. It is important to note that whilst the UNECER90:02 thermal fatigue test calls for 15 cycles to be completed, it actually requires, as a minimum, a result no worse than the OE part in terms of the number of cycles achieved before failure.

The tests also draw conclusions from the wear figures claiming longer pad and disc life with the solid disc. However, if you look at the actual figures and not the percentage values, then you see there is 0.046mm difference in pad wear and 0.004mm difference in disc wear. These differences are not significant. A solid disc has its place for particular types of application but for the above reasons, Fras-Le will only supply a UN ECE R90:02 approved product that is safe and cost effective.

Fras-Le has recently introduced its CV braking solutions to the UK market. This marks a significant milestone in the company’s global expansion strategy. With a reputation for excellence, technological innovation, and sustainability, Fras-Le is well positioned to become a trusted partner for workshops in the UK’s commercial vehicle sector.

As the transportation landscape evolves, Fras-Le’s commitment to delivering cutting-edge CV braking solutions promises to play a pivotal role in shaping the future of brake systems in the UK.