As road haulage becomes ever more complex, driven by new regulations, rising cost pressures and greater expectations of fleets, operators are increasingly turning to digital solutions to enable them to remain competitive in the market. In response, Wabco is introducing TX-Trailerpulse™.

This year, Wabco launched a new advanced trailer monitoring and remote diagnostics solution, TXTrailerpulse, alongside its trailer health portal TX-Trailerfit™. The company’s offering now includes advanced telematics, Big Data driven fuel management systems and enhanced connectivity via the Internet of Things (IoT) and cloud-based systems.

Here, Benoit Dessart, WABCO Global Business Line Leader Trailer & Cargo Connectivity, explains what workshops and operators need to know about the new solution.

Behind the scenes

TX-Trailerpulse is a trailer-focused IoT connectivity solution that combines realtime track and trace functionality with additional remote trailer health and diagnostics information. The solution is the first of its kind, combining both trailer tracking and advanced remote diagnostics at a cost that enables fleet-wide deployment across all trailer types. Directly connected to the trailer electronic braking system (TEBS), the solution captures and processes TEBS and trailer diagnostics data via the web-based TX-Trailerfit portal. This enables assessment of the technical health of the trailer and visualises trailer diagnostics features, including ‘fault code-to-plain language’ translation, root cause indication and repair information. Due to the role-based nature of both portals, several users with different ‘roles’ are able to access the data and portals separately or simultaneously.

The system can be easily installed with its two-point housing layout and single-cabled connectivity to the TEBS system – either as an OE fitment or as a retrofit option for fleets. Once connected, TX-Trailerpulse automatically powers up, connects to the GNSS and GSM network through its integrated module and starts broadcasting data via an embedded SIM card. The device is IP69K-rated to ensure it is resistant to dust, water and heat ingress, with an operating range of – 40°C up to +85°C, making it particularly well-suited to outside installation on trailers and for daily use in adverse environments. Data generated by TX-Trailerpulse can be further integrated with other third-party software systems via Web Services.

The value of diagnostics data

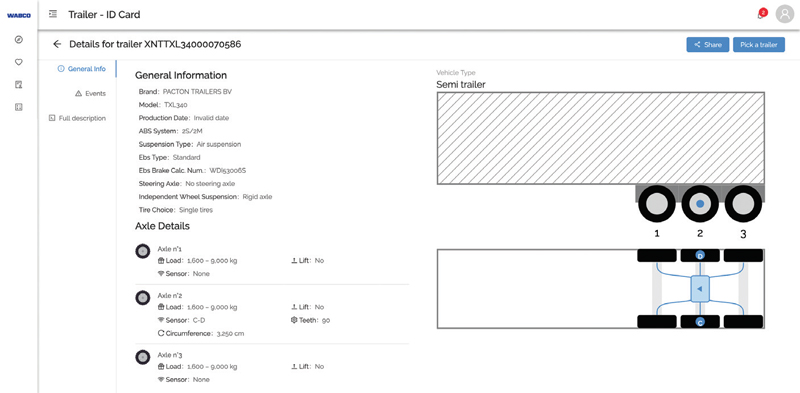

In addition to providing the same information to the back office that a technician would receive from a physical readout in the workshop, TX-Trailerpulse makes data available remotely and in real time. Specifically, the solution provides a wide range of trailer information, including trailer brand, model, EBS type and axle configuration.

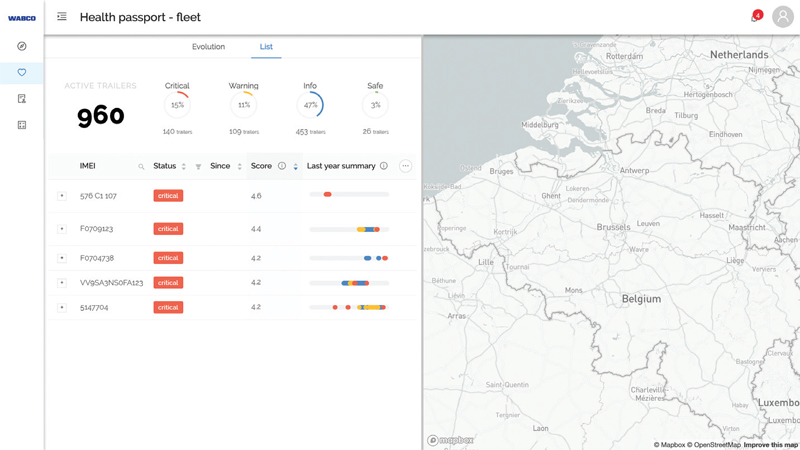

TX-Trailerpulse processes the diagnostics code history, including maintenance and uptime management as recorded by the Operating Data Recorder (ODR), specifically recording events such as tilt alerts, insufficient tyre pressure, RSS events, warning lamps, supply pressure warnings, wheel-speed, demand pressure and axle load sensor data. The occurrence of any new diagnostic trouble code or EBS warning lamp forces a new read-out of ODR data and results in a constantly updated trailer health score for each vehicle. An historical overview of these error codes and warning alerts in the TX-Trailerfit portal enables patterns or reoccurrences of technical issues to be readily identified and addressed.

Taking DTCs and contextual data into consideration, a health score is generated for each individual trailer within a fleet, allowing operators to prioritise maintenance activities and to act preventatively to mitigate any degradation of trailer health scores.

Fleets can securely share these overviews with workshops, enabling accelerated repair and maintenance by improving the communication flow on trailer health throughout the service chain, as well as generated error codes and diagnostics data. As a result, workshops are better prepared to perform analysis, determine the best course of action, and take prompt maintenance and repair decisions. Data captured on trailer health also enables fleet operators to more easily comply with regulations related to road safety.

The future of maintenance and repairs in workshops

Thanks to enhanced connectivity and the rich data flow from telematics solutions, immediate access to up-to-date digital trailer ID cards is possible. These provide a status overview of the applicable mechanical parts even before the trailer is called in for maintenance or repair. This allows workshops to schedule maintenance and parts replacement at exactly the right time, as well as preschedule technicians, eliminate unnecessary maintenance, and reduce the chance of vehicle breakdowns. Helping to significantly reduce vehicle downtime, this can be further improved as the system can automatically recommend maintenance slots based on key parameters, including vehicle health scores, trailer utilisation rates, mileage completed, load undertaken, date of last maintenance and any combination of these factors.

The workshop is a hugely important stakeholder in the servicing process, and by utilising leading FMS solutions and connectivity technologies, workshops can make their services even more effective and efficient. In turn, this helps to improve the bottom line of workshops, fleet operators and their customers.