As trucks become ever more complex, diagnostic systems have had to become more sophisticated. Toby Clark takes a look at the features you should look for and the questions you should ask if you’re in the market for a diagnostic package.

The modern technician needs diagnostic kit, but vehicles are becoming more and more complex – as are the sub-systems and accessories that go with them – so diagnostic equipment needs to become more sophisticated: for example, Jaltest’s latest software includes information on over 14,000 different vehicles and components. And with this sophistication comes the risk that diagnostic devices – and particularly thirdparty, multi-brand types – will become difficult to understand and use effectively.

So, manufacturers are putting effort into making their operating systems flexible, their diagnostic information easier to understand, and their functions easy to implement; for example, TEXA’s latest IDC5 diagnostic software will automatically scan and download the vehicle’s VIN code and use it to identify the make and precise model.

While car diagnostic systems have almost become almost commodity items (‘code readers’ for the European On-Board Diagnostics (EOBD) standard or the US OBD-II standard cost just £10 on eBay), truck diagnostics is a more specialist market. Some Far Eastern sources offer ‘truck-compatible’ code readers and scanners for £80 or so, but these are usually limited to the US HD-OBD standard.

Although truck manufacturers have not standardised on a single interface socket (unlike cars, which settled on OBD-II more than decade ago), they use the same underlying information protocols, so that multi-brand diagnostic units should work properly. The diagnostics firms offer the appropriate cables, and one said, “it doesn’t make a big difference – we’re talking about one, or maybe two, per manufacturer”.

Whichever the system, you want to be sure that its database can and will be updated regularly; most of the big players promise (and deliver) three significant updates a year.

The next step is ‘pass-thru’ technology, which lets you ‘pass-thru’ to the OEMs’ own websites to reprogram ECUs with official OEM updates.

The Pass-Thru regulations J2534 and ISO22900 (from Euro VI on) define the standard reprogramming interfaces in terms of software. Delphi says that with its DSFlash unit “you’ll be able to perform dealer-level diagnostics, download software updates, reprogram ECUs and access OE technical data and service schedule information, without the need for expensive dealer-only tools”. Manufacturers allow customers to subscribe to system updates, but charge for the service.

Some diagnostic units incorporate a data-logging function (Delphi calls it a ‘flight recorder’) to record the behaviour of the vehicle on the road. This is valuable to isolate intermittent problems which may only occur while driving.

Advancing technology

Manufacturers are increasingly incorporating other features into diagnostic gear; for instance, Delphi’s DS Diagnostic tablet has an optional module and software package to test ADAS (Advanced Driver Assistance Systems) components such as cameras and radar units, and perform static calibration in the workshop.

A number of models will also communicate with other components: TEXA’s IDC5 operating system can be used to reprogram ZF’s AS-Tronic gearboxes and a number of EBS braking systems. The system will also allow you to reprogram replacement ECU modules as they are fitted, to carry over the parameters from the previous unit. Similarly, Jaltest’s software includes the parameters for testing and communicating with refrigeration units from the likes of Carrier and Thermo King.

One very important feature is the ability to set PTO parameters to suit a particular operation: vehicles with complex hydraulic systems such as car transporters, for instance, often need very specific parameters for idle shutdown, and the ability to respond to remote start controls appropriately.

Some diagnostic systems will even communicate with other maintenance equipment: TEXA’s AXONE Nemo diagnostic tool can be linked to one of the firm’s AIR2 SAN ozone-generating vehicle sanitisers, to monitor and control the progress of the cleaning programme.

Delphi is one of the world’s biggest OEM suppliers of vehicle electronics and injection systems, and offers its own multi-brand diagnostics system. Its primary product for the UK is the DS150E VCI (Vehicle Communication Interface). It plugs into the diagnostic socket and has a Bluetooth connection to either the workshop’s own PC or a dedicated tablet such as Delphi’s DS450E, for a ‘plug & play’ option. Either version requires Delphi’s DS software, which can be bought in a package or with the hardware or on a time-limited licence. Likewise, Bosch offers its KTS Truck unit on its own — you buy the ESI[tronic] 2.0 Truck software separately — or with a matching tablet or laptop.

Texa’s vehicle interface is called the TXT Multihub, and unusually it has a built-in display to show basic information such as battery voltage; the firm’s Axone Nemo 2 is a ruggedised 12in tablet. The firm also offers the eTRUCK, a small device which plugs into the diagnostic port, and is meant to stay there; it monitors the condition of the vehicle constantly, allowing a certain amount of predictive maintenance.

Eclipse Automotive Technology claims that its Jaltest system is “the industry’s number one commercial vehicle diagnostic package”, and its package includes twelve months of technical support on both the vehicle side and the IT side.

Cloud-based diagnostics looked set to become a big thing in 2016, when Nebula Systems launched its MECH5 system. This promised that a cheap hardware interface could connect (via Bluetooth) to the Web, and then offer comprehensive diagnostic services for almost any vehicle, constantly updated with no need for periodic downloads.

The service used a monthly subscription model, but it seems to have gone offline now.

At the moment, remote diagnostics is limited to light vehicle services such as OSCA (see picture below, right), but this pay-as-you-go model may become more useful for vehicles with complicated accessories which need specialist attention. Even the most straightforward diagnostic system is no good without training: many older technicians have had no formal training in the use of diagnostics, and even now it is not always among the first things that apprentices learn. At least one industry figure reckons it should be introduced right at the beginning: “They let them use a spanner at 17 — the diagnostic machine is the modern spanner. You couldn’t do without it”.

Others at least want to be sure that apprentices are taught to look and listen for basic faults first: one told us, “It makes for a better diagnosis, rather than going straight for the diagnostic kit and missing the obvious — often you get a very basic fault causing really advanced fault codes”. But even the most experienced technicians can benefit from a refresher course.

The best-known retailers offer their own training schemes, or have teamed up with the diagnostics manufacturers: Hickleys’ Training Academy is based at its Taunton HQ, while AP Tech offers Andrew Page Auto Education courses at a number of venues, and Eclipse runs specialist courses such as an ‘Advanced Trailer Jaltest Course’.

OSCA’s 2.0 hardware interface links the vehicle’s diagnostic system to a workshop’s WiFi network. You contact OSCA via a web browser, and they diagnose faults and reprogram systems remotely, with a transparent menu of prices. Although, the services are limited to cars and some light commercials at the moment.

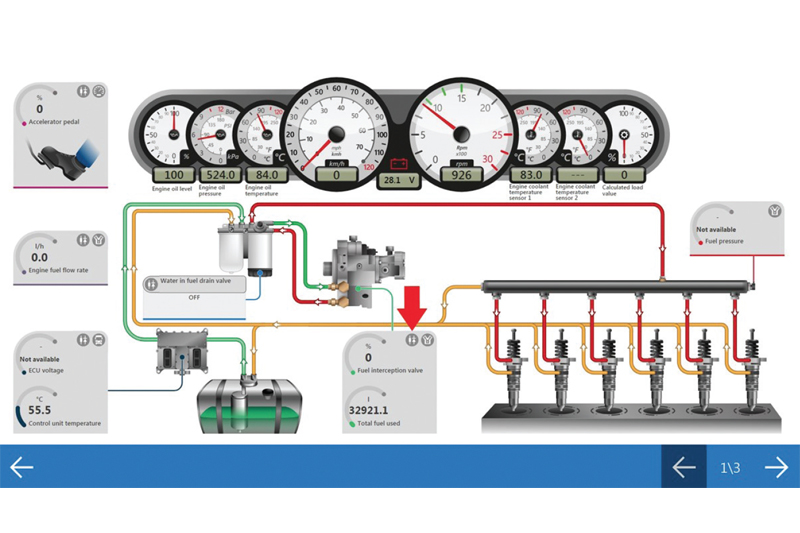

Sometimes specialist kit is needed: for example, Delphi’s HD3000 ‘high pressure diagnostic toolkit’ tests fuel injection systems (common rail or unit injector) without having to alter ECU parameters or dismantle the system. A technician can safely set and control any pressure test point of an engine, at up to 3,000bar. It has eight dedicated test routines and can even perform a cleaning procedure.