Bob Wood, a technical engineer at Total Lubricants with some 45 years’ experience, explores lubricant analysis and how it can benefit commercial vehicles.

Lubricants are often thought of as the lifeblood of an engine. Effective lubrication can maximise service life, improve engine cleanliness and wear protection, and reduce unplanned and unnecessary maintenance costs and unscheduled downtime.

It is vital that oils and coolants are performing effectively and doing their job to keep hard working vehicles running smoothly. Incorporating regular lubricant analysis into a programme of proactive vehicle maintenance will ensure lubricants are in good condition and can reveal useful diagnostic information that can be acted on before major problems arise.

Like a blood test, lubricant analysis can help identify potential ‘health issues’ within a vehicle’s components. A small representative sample of in-use oil is taken which is analysed in a laboratory to assess the condition of a truck’s engine and to check features such as the lubricant’s viscosity and whether it contains any contaminants that could reduce the effectiveness of the oil and cause increased wear on vehicle components.

Lubricant analysis can find out the following:

- How worn the engine’s components are

- Whether the lubricant is contaminated

- Characteristics of the lubricant, such as its viscosity

- Additives and elements present in the oil

- The engine’s wear compared to other identical engines

The results of lubricant analysis enable the workshop or fleet manager to take any appropriate action needed.

Oil contaminants

Engine oil may become contaminated with water, fuel, dust, soot, and coolant. All of these contaminants can lead to degradation of the lubricant, which reduces its effectiveness. When water gets into the oil, it can cause sludging of the oil ways which can prevent the oil circulating around the engine. It can also cause corrosion.

Fuel dilution, which can happen when the fuel injectors leak, or when the fuel is not fully burned off in the combustion process, can lead to the viscosity of the oil being too thin to withstand heavy loads and speeds, resulting in greater friction between metal surfaces and wear on the components.

Dust, or fine silica particles, can also infiltrate into the oil through the air filter. When dusty air is sucked into the engine for combustion, it can affect the engine. It is like diamonds scratching glass – the silica scratches the metals which produces abrasive wear particles that can damage the engine components. This could indicate that it is time to change the air filter and the oil.

In diesel engines, the soot can be generated through incomplete combustion that can escape into the oil and thicken it. Too much soot in the oil will block the oil wells and can cause engine seizure.

Another oil contaminant to monitor for is the anti-freeze (or coolant) from the cooling system. This can leak into the oil, which can be caused through negligence, because there is a leak in the head gasket, or because the cylinder liner has become porous. The coolant can chemically react with the engine oil and form a sludge, preventing the oil getting to the oil wells.

Coolants

Coolants are usually checked less frequently than oil but often remain in an engine much longer. However, as well as oils, coolants are essential to engine operation and ensuring coolants are in good condition helps promote engine health.

It should not be overlooked because failure of the coolant system can cause engines to overheat, which reduces the lubricity of the oil and leads to deterioration, which is one of the most common causes of engine failure.

Simply observing the colour and appearance of the coolant can also indicate whether it is time for it to be replaced or if further investigation may be needed; for example, if the colour has changed significantly, or the presence of wear metals are visible. Coolant effectiveness does of course deteriorate over time, so it is wise to periodically check the concentration of the coolant. If it is too low, corrosion will occur, and if it is too high, the cooling effectiveness can be reduced.

The pH should also be checked to determine the coolant’s acidity or alkalinity. If there is too much acid, it will be corrosive, so the reserve alkalinity should be measured, which will show the amount of additive remaining and, therefore, its ability to neutralise acids and prevent corrosive damage.

Just as wear metals can infiltrate the oil, so too they can get into the coolant. Analysis can identify what wear metals are present in the coolant and indicate the likely cause of the problem.

Total ANAC

Total ANAC is Total’s engine oil analysis service. ANAC specialists have performed lubricant diagnoses on millions of samples sent in by HGV fleets across the world, creating and expanding a database of engine problems based on the composition of the oil samples. By comparing the wear metals of the engine to the expected wear of the engine at a certain number of kilometres driven, Total ANAC can calculate the wear coefficient for the engine at the time the oil sample was taken. So, assuming the engine is following the expected wear patterns, the wear coefficient is one. Anything above one can be a problem.

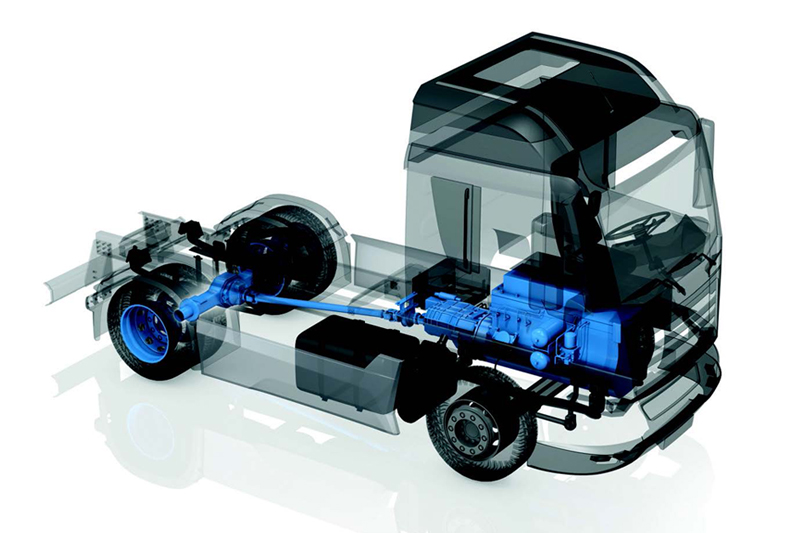

By comparing samples against its comprehensive database, Total ANAC finds exact matches to diagnose potential troubles within the engine. Other tests can be used to look at the condition of transmissions, hydraulics, and coolants.

As well as pre-warning of mechanical issues, understanding engine health by using lubricant analysis enables the accurate planning of maintenance schedules, optimised oil change times, and improves the reliability and performance of vehicles, in turn increasing their lifespan and reducing the total cost of ownership (TCO).