David Hall, Managing Director of Totalkare, explains the company’s decision to introduce its first non-lifting product and how the move has been received.

For a company that has spent more than 40 years supplying a range of heavy-duty vehicle lifts to UK clients involved in the bus and coach, commercial motor, and heavy haulage sectors, this was certainly seen as a bold move. At last year’s Commercial Vehicle Show, Totalkare introduced its first brake tester.

David Hall explains: “It certainly proved a wise decision. Our sales targets for the first 12 months were surpassed in just 100 days and our systems are installed and currently being used across numerous sectors and with several local authorities – all ably supported by our nationwide team of field service engineers.

“Making sure we offered the best products was our first aim, but we knew we had to replicate the same level of technical expertise, service, and maintenance we offer across our lifting solutions. With this in mind, we appointed two sector specialists in Graham Simmons and Luke Simmons and that gave us immediate traction.”

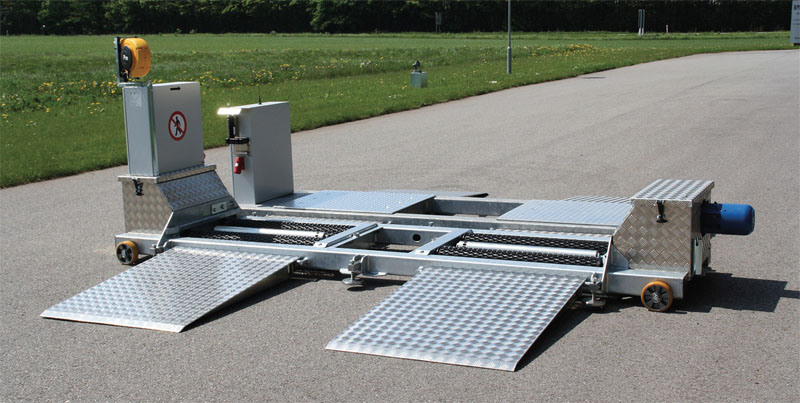

Available as a mobile or in-ground product, Totalkare’s design involves the latest technical solutions that makes it suitable for testing all vehicles up to a maximum axle load of 20,000kg. It has DVSA approval, is hot galvanised to improve durability, and features comprehensive load simulation system and app technology so that data and analysis can be completed on a smart phone or tablet.

The Totalkare brake tester can also be adapted to allow for testing vehicles with a wheel span between 880mm to 2880mm and those with a very low wheelbase that you would usually find on small light vehicles and city trucks.

East Anglian transport specialist Transam Trucking is one company that has benefitted from Totalkare’s brake testers.

In what is believed to be a UK first, the company has reduced the time it takes to test each of its 130 vehicles at full load capacity from one hour to just 15 minutes – a major time and cost saving with staff redeployed elsewhere in the business.

Technical experts from Totalkare worked quickly to identify the right solution and install the brake tester, which needed some form of civils work but not the usual deep pit. The company also provided extensive training for all Transam Trucking staff so they could get the most out of the technology as quickly as possible.

“Regulation is coming in that will require you to ensure that every vehicle you put on the brake tester has a full load on it, which will be very time intensive when you’ve got 600 tests to do a year,” explains Mike Wickham, Workshop Manager at Transam Trucking.

“We knew we had to find an alternative to the manual approach of loading, so spent a long time researching different technologies, finally settling on the Totalkare in-ground brake tester with load simulation automatically applied.

“It has only been in a few months, but the difference is already huge, with the capacity to test 20 vehicles – ranging in size form a sprinter van to a 53-feet arctic – every day.”