As various industry reports have shown over recent months, tyre safety should be a top priority for fleets. With an aim to reduce downtime and improve safety, Sigmavision highlights the issue and explains how its TreadReader hand held scanner can help workshops demonstrate potential issues to customers.

The cost of vehicle downtime

Every minute a commercial vehicle is off the road costs a company money. An Autoglass survey estimated the average cost in terms of lost revenue is £727 per day, but it is reported that 40% of fleet managers are unable to estimate the business cost of having one of their vehicles off the road.

Vehicle downtime comprises not just replacement parts or service labour, but also employee wages, productivity and reputational impact if an appointment cannot be kept or a delivery made. Ensuring that fleet managers are aware of this cost is the first step in improving the utilisation of a vehicle.

The key is to take a proactive approach to avoid unscheduled repair work, including daily vehicle checks, and a clear process for rectifying faults.

Preventative vehicle maintenance

A crucial aspect of preventative maintenance is a robust tyre inspection and maintenance policy. Chairman of Tyresafe, Stuart Jackson, campaigns for greater awareness of tyre maintenance. He highlights that defective tyres dramatically reduce the effectiveness of a vehicle’s steering and braking systems, with an increased risk of dangerous deflations.

This is underlined by Department of Transport (DfT) figures which show that, of the 48 people killed in road accidents attributable to vehicle defects last year, 58% were due to defective tyres. The DfT also reported, out of the 2,855 casualties caused by defective vehicles, dangerous tyres were cited as a contributory factor in 968 cases.

Tyre complacency

Technology, such as tyre pressure monitoring systems (TPMS) and run-flat tyres, add further to the complacency some drivers and operators feel about tyres.

Under-inflated tyres cause excessive flexing within the structure of a tyre, meaning the contact with the road is concentrated on the edges of the tread. Under-inflation also reduces the vehicle’s fuel economy, road-holding, braking, steering and resistance to aquaplaning.

An under-inflated tyre will run hot due to friction and it will be prone to a blow-out. When a tyre is under-inflated, it contains insufficient air to support the weight of the vehicle and make driving unsafe.

Over-inflated tyres bring their own problems. They concentrate the contact with the road in the centre of the tread, leading to accelerated wear in that area. They also result in an uncomfortable ride and make the tyre more susceptible to impact damage.

TreadReader

TreadReader

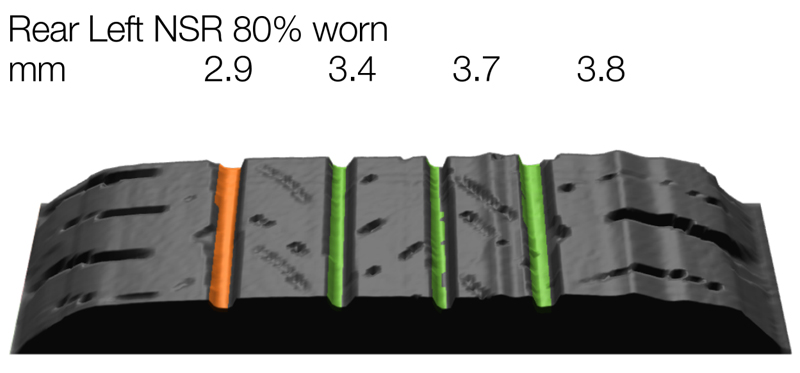

Ultimately, the early detection of tyre problems by identifying unusual tread wear patterns is critical. To assist in this process, Sigmavision’s TreadReader technology produces a three dimensional image of a vehicle’s

tyre tread depth.

The technology is already used by global tyre manufacturers, including Continental, Nokian Tyres and garage

equipment supplier Hunter Engineering. The system also diagnoses any wheel misalignment or incorrect tyre inflation.

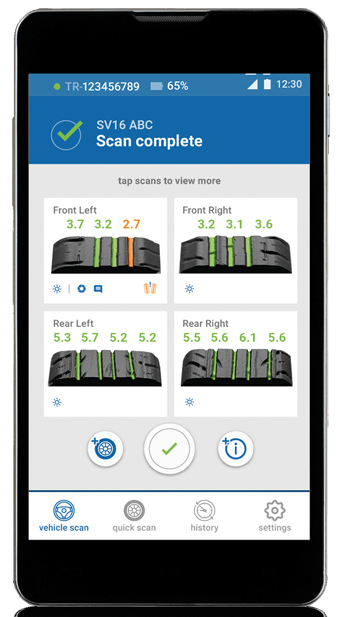

Visitors to the Sigmavision stand at Automechanika Frankfurt in Hall 12 will have seen the TreadReader hand held scanner being demonstrated live. These products are designed for all workshops, dealerships and tyre retailers wanting to increase tyre sales and wheel alignment revenues. All products produce 3D scans, which are viewed on a phone, tablet or computer screen.

The TreadReader hand held scanner is ideal for commercial applications, and offers users a digital point-measurement device, rather than using a manual depth gauge, for improved accuracy. A compact and lightweight device, it produces tread depth readings for the full width of the tyre and 50mm around the circumference.

The scanner is operated by sliding the device from one edge of a tyre across the tread face.

Colour-coded 3D scans produced from the device accurately indicate tread depth and can reveal badly worn or unevenly worn tyres, symptomatic of under-inflation, wheel misalignment or worn suspension. The calculated data can be imported into any fleet management system to log tyre scans and produce wear analysis or tyre lifetime modelling.

At the show, Sigmavision also launched a new TreadManager Service. Designed to increase tyre sales revenue and boost turnover from tyre-related services, TreadManager reports tyre measurement data and management information for all vehicles scanned using TreadReader tyre measurement devices.

The reports contain the distinctive TreadReader 3D tyre scans, to support in building trust between vehicle operator and tyre provider. Multiple scans for the same vehicle can be tracked over time, in order to predict tyre lifetime and advise operators when to book in for replacement tyres.

For larger workshops and dealer locations using one or more TreadReader devices, TreadManager can track activity levels by device and by technician. Also intended for multiple workshop locations, the software offers a Group User profile, for reporting across any number of technicians, workshops and franchises.