Karl Ridings, Sales Director UK & Ireland – Aftermarket of UFI Filters, explains the main CV oil filter functions, shares tips for oil filter replacement, and provides an insight into how the company sets trends in oil filtration technology.

Heavy vehicle manufacturers must ensure the highest levels of efficiency and safety, particularly for heavy duty vehicles, which travel long distances every day. Separating the good from the bad, oil filters are the hidden heroes that keep commercial vehicle engines running. This is why it is important to be able to rely on top-level suppliers, such as UFI Filters, with its complete oil filter range.

Clients who choose a premium filter from an OE supplier like UFI Filters benefit from integrated processes covering R&D, quality, and testing that are tailored to meet the specific needs of the OE and legislative requirements. Although filters look very similar from the outside, the performance of any filter (e.g., pressure control, quantity and type of filter media used, leakage protection, sealing material, etc.) can deviate enormously.

For any type of filter, UFI recommends the repairer ensures that the selected filter corresponds to the application suggested in the catalogue as the use of incorrect part numbers is a frequent cause of malfunction or even collapse of the filter.

UFI also recommends the repairer should follow service procedures as suggested by the vehicle manufacturer and filter element manufacturer in order to achieve convenient service operations (e.g., to avoid oil dirt in the engine zone) and prevent functionality issues.

A step ahead

Over the last few years, oil filtration has changed, such as with the development of advanced media, the filter design, or the integration of functions into one module. UFI’s filter products already fulfil and exceed latest OE requirements like the operation under high working pressure conditions, the green and reinforced design of the components, like body and cartridge, and sensors with multiple functionalities.

With its vast experience and know-how in the development of new materials, UFI’s experts have introduced the patented Durafilter oil filtration solution for heavy trucks, which uses a media composed of synthetic microfibres to guarantee extreme performance, with a travel capacity of up to 100,000 kilometres.

Another demand is to be able to integrate the heat exchanger into the module. That is one of the reasons why UFI’s heat exchanging products are highly complementary to its filtration business.

At UFI Filters, there are three research centres with laboratories and specialists who constantly work to ensure the products provided exceed today’s high needs required by commercial vehicle manufacturers.

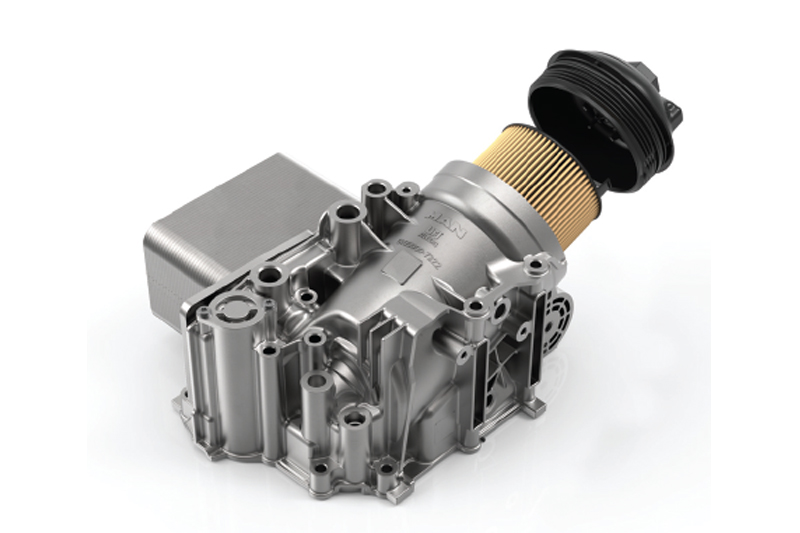

The result are oil modules such as the one recently introduced for the latest MAN D15 engine for Heavy Duty Euro 6d applications. The engine is also applied to MAN’s new TGX range that has been elected International Truck of the Year 2021.

UFI’s aftermarket customers benefit from its capabilities in the OE sector. It has developed an aftermarket filter program that incorporates its OE filters and its philosophy of meeting the demands of tomorrow today.

Top tips for oil filter replacements

Although filters should be replaced in line with the indications of the vehicle manufacturers, in particular for the oil filter, it is recommended for the fleet or vehicle operator to replace it even more often.

If a vehicle is frequently driven short distances, like trucks doing intensive stop-go urban deliveries, an increased degradation of the oil will result. A good indication for this is the condition of the emptied oil.

Particular fitting mistakes on oil filters that can be found:

- Use of non-suitable tools for the type of filter

- Insufficiently cleaned gasket contact surfaces on seamed cartridges

- Gasket on the cartridge is not oiled

- Gasket supplied with the spare part is not replaced

- O-rings are crushed or twisted

- Tightening torques or specific precautions are not correctly observed (e.g. manual tightening on seamed cartridges)

- Damaging particles can remain in the engine by poor filtration of the oil filter. Poorly fit oil filters can compromise engine performance and reliability, and increase fuel consumption and harmful emissions