What are the benefits of retread tyres?

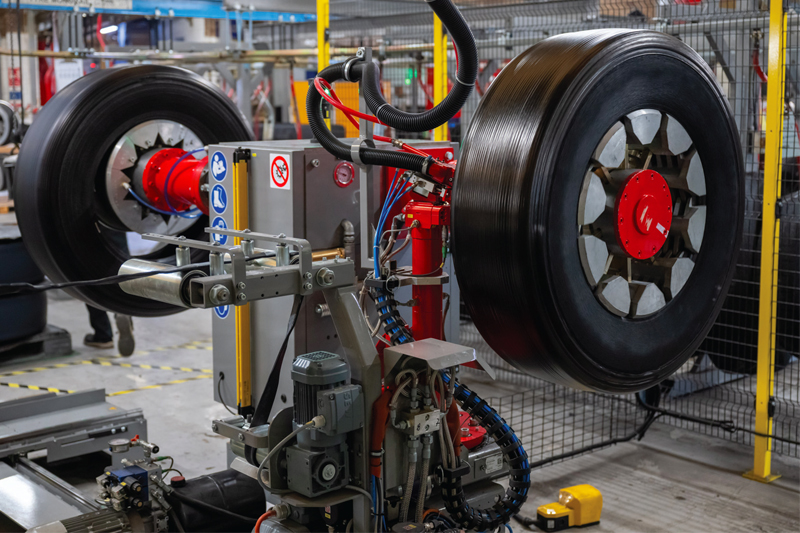

CVW visited Bridgestone’s Bandag Hotread plant in Bourne, Lincs, to find out more about the company’s hot cure retread tyre offering.

Why the emphasis on hot cure products?

With the launch of Hotread, Bandag now offers both pre-cured and mould-cured retreads product solutions. Due to customer demand, we are now ramping up production of hot-cure retreads. These mould-cured retread tyres feature the same performance as the Bandag premium pre-cured tread range.

We will continue to offer precure (cold) retreads in addition to Hotread, allowing fleets to select the right tyre for their application and wheel position. One important feature is the new sidewall design, ensuring the tyres have a look-like-new appearance, which more and more customers want.

What is currently the split between hot and cold?

For many years the plant has used both production processes, but with cold contributing around 60% of the total volume. With the new focus on hotcure products we expect the production to more closely mirror the UK market which is estimated at around 75% hot retreads.

In Europe the market is split roughly 50/50 between hot and cold, while in North America (the world’s largest retread market) cold makes up the vast majority. Both technologies are used in climates ranging from the Northern Scandinavia to the Sahara.

What are the benefits of retread tyres?

There are both environmental and sustainable benefits from retread tyres. Retread is economically good for the customer and it is environmentally good for society, so it makes economic and environmental sense. Retreads extend the wear life and performance of premium tyres, delivering near-new tyre performance while lowering the total tyre cost per kilometre for fleet owners and managers.

Retread tyres use less than one-third the amount of raw materials used in new tyres and enable the reuse of other tyre components, such as the casing. The retreading solution significantly contributes to the reduction of discarded tyres as well as the reduction of waste in communities.

Why is retread such a good option?

- Significantly lower total tyre cost per km

- Reliability and performance similar to new tyres

- Reduced waste, raw materials consumption and carbon emissions

- Fast, flexible and high-quality service

Why do casings matter?

Premium quality truck tyres are designed and built to give superior performance through their first life and continue to be robust enough to continue giving great performance in their second or third lives in a quality retread.

It is critical for the overall performance and reliability of a retread that good quality casings are selected and utilised. Only casings that have passed stringent quality checks are used in the latest generation patterns. Other premium manufacturer casings are utilised in our other products, but again only after passing our stringent inspection processes.

Are retreads enjoying something of a renaissance?

More and more companies are putting sustainability higher on their agendas, and this is leading to increased opportunities to show that retreading has a lot of benefits for fleets. Fleets can save a significant amount of money and contribute to a sustainable society.

For example, Bandag retreads contain up to 75% recycled and reused material, contributing to sustainability and the circular economy. Reusing the worn casing as the main retread component creates a saving of up to 70l of oil, up to 32kg of rubber and 14kg of steel. Bandag also significantly contributes to a decrease in tyre cost per kilometre for fleets, equivalent to an up to 30% reduction in cost compared to a new tyre. Re-treaded tyres generate up to 80% fewer CO2 and green house gas emissions than new tyres in production.

Should there be an EU tyre label for retreads? Why?

We are still waiting for the EU regulator to publish a proposal for TBR retread labelling. This means that at the moment we can’t give an answer on how this will impact operations as we first need to get some more clarity around the test method and grading approach. However, we believe in giving customers the information to allow them to make informed decisions and therefore we welcome the opportunity for our retreads to further demonstrate their advantages through labelling.

What plans are there for retread business to go carbon neutral? What are the time scales and how does it intend to do this?

Bridgestone has stated its aim for the entire corporation to use 100% sustainable materials and be carbon neutral by 2050. By 2030 it is aiming for a 50% reduction in CO2 emissions from the 2019 level, and steady progress is already being made towards these targets.

Retreading plays a critical role in improved resource productivity and reduced CO2 emissions and this is why Bridgestone has been accelerating its efforts to promote the benefits of retreading to its customers.

What is Fleetcare?

Fleetcare is an integrated tyre and fleet management solution that combines our premium tyres and tyre management solutions with Webfleet. It provides a host of benefits, with total cost of ownership reduction at the forefront.

Customer satisfaction, time saving, regulatory compliance and increased sustainability, safety and security are also provided in one user-friendly package. Fleetcare delivers business benefits through IoT and data driven insights and services. If you’re looking for a comprehensive and modular solution package that adds cost control and automation to your daily work, then we might just have the answer!

What is Enliten technology?

Enliten is a technology which reduces the rolling resistance of a tyre by up to 30%, and weight by up to 20%. It extends the driving range of EVs and also contributes to reducing environmental impact thanks to improved resource productivity.

This enables tyres with embedded Enliten technology to help reduce fuel consumption and CO2 emissions in combustion vehicles, while also extending battery life and vehicle range in electric vehicles.

What will a connected tyre world look like in the future and how are tyres getting ‘smarter’?

We predict that connected vehicles will soon use data from tyres to feedback real time information about driving conditions (e.g. icy sections on roads) road conditions (e.g. pot holes) and driving styles (e.g. harsh braking) amongst many others. If a council receives data that tyres are slipping or vehicles are braking harshly at a particular junction, they can focus on improving the conditions there – saving costs and improving safety.

Intelligent tyres are the future. Tyres that communicate both with the vehicle, end user and tyre consultant/fitter will become the norm in years to come. RFID (Radio Frequency Identification) is the starting point and this technology is already advancing at speed with new technology like pressure sensing, temperature reading, tread depth measurement, mileage recording and many more features.

Tyre systems that communicate with the end user on their mobile or send an email message to a tyre dealer are already available for Commercial operations (truck fleets) and these systems will be rolled out to other vehicle groups over time. Bridgestone is investing heavily and working with IT partners in this area of intelligent and connected tyres.