What can go wrong with EGR systems?

EGR systems play a pivotal role in emissions reduction but it’s a hard life. Highway Automotive looks at what can go wrong and what to replace.

With the environment and related issues clearly in the sights of governments around the world, there is a collective responsibility to ensure that all the internal combustion engines currently in the vehicle parc are operating to their optimum efficiency. Central to this objective is the exhaust gas recirculation (EGR) system, as it actively reduces the emissions that these engines naturally produce, keeping unwanted pollution to a minimum.

Although many will be familiar with how the system operates, others will find it useful to understand the fundamentals in order to help them recognise the priorities when diagnosing faults and replacing failed components.

Operating temperatures

To achieve the necessary high rates of EGR, regulating throttles are used in the intake air system as they generate the pressure difference required between the exhaust gas side and intake side. After the fuel/air mixture has been burned, some of the exhaust gas is taken through the EGR valve, which regulates the subsequent mixing of the exhaust gas with the intake air. This means that less oxygen reaches the cylinder and less oxygen means a lower combustion temperature, which significantly reduces the quantity of nitrogen oxide (NOx) the engine produces because the higher the temperature, the more harmful NOx is produced.

The valve is therefore a key component within the EGR system as it regulates the quantity of exhaust gas that is returned.

EGR valves come in various designs and models, both pneumatic and electrical and, since simple EGR is often not sufficient to fulfil emissions standards, some come with connections for cooling. This is because cooled exhaust gas further reduces the combustion temperature, which once more lowers the amount of NOx that is produced.

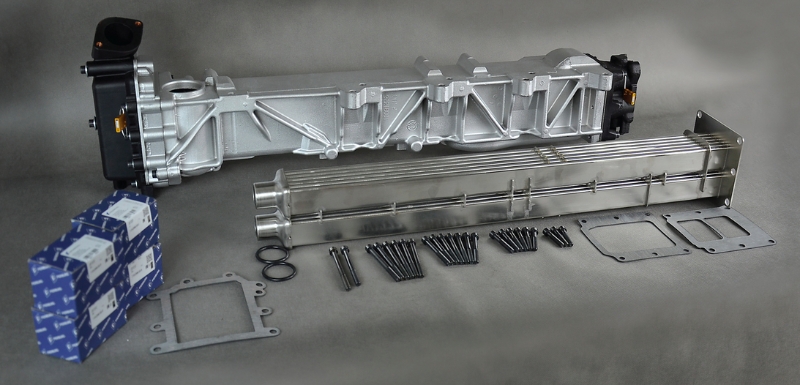

In common with all the components in the EGR system, coolers are exposed to the extreme heat, pressure and corrosive nature of exhaust gas, so must be manufactured from materials highly resistant to these conditions.

Many EGR coolers now feature an electrical or pneumatic bypass flap, which allows the exhaust gases to be directed past the EGR cooler in the warmup phase, to bring the engine and catalytic converter to operating temperature as quickly as possible. This also reduces noise and the raw emission of hydrocarbons in the warmup phase. Bypassing the valve is also possible if high exhaust gas temperatures are required to regenerate the diesel particulate filter, for example.

Naturally, sensors also play a pivotal role within the EGR system, particularly the NOx sensor, which is mounted in the exhaust system and conveys vital information to the vehicle’s electronic control unit (ECU) to allow it to adjust the air/fuel mixture and the regulation of the EGR valve, as examples. Constantly exposed to a stream of very hot exhaust gas, the NOx sensor is also subjected to an extremely hostile working environment.

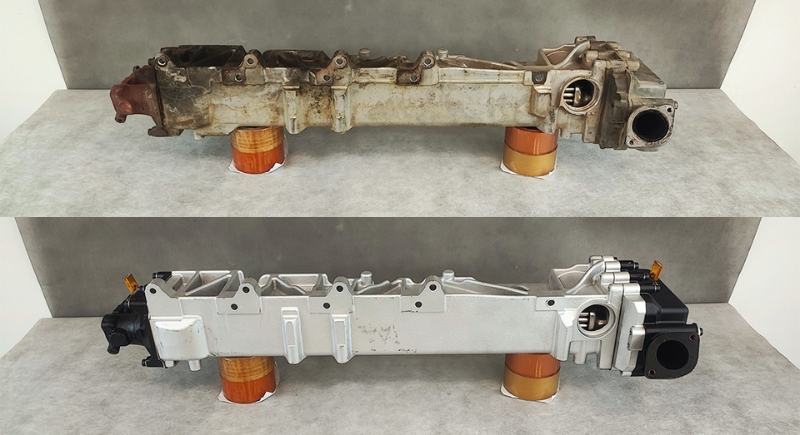

As a result, over time the performance of the individual elements within the EGR system drops, due to either natural wear, or because of the effects of other faults that occur within the engine’s systems, so they, or their associated parts, will need to be replaced, which is when commercial vehicle workshops and fleet operators should really seek out a premium quality, aftermarket solution.

If all the above sounds a bit overwhelming, Highway Automotive can also support workshops with technical advice, such as the following guidance when replacing NOx sensors.

Top installation tips

The following guidance is particularly important when the original factory exhaust system is being repaired.

When installing a new NOx sensor, remember its measuring tip cannot be cleaned mechanically nor chemically, and the tip must be perpendicular to the exhaust gas stream. Therefore, the sensor must be mounted on a straight section of the exhaust pipe, in a location where the exhaust gas temperature is high. To prevent the measuring tip from being damaged prematurely, the sensor must be mounted on the upper wall of the exhaust pipe. This position protects it against water condensing in the exhaust pipe while the engine is warming up.

After installing the new sensor, remove all errors and previous adaptation data from the memory of the ECU and carry out the new sensor adaption procedure. Incorrect installation of the sensor affects its response time, distorts the data transmitted to the ECU and reduces its service life.

Furthermore, it must be noted that ‘universal’ NOx sensors do not exist, rather they are tailored to a specific vehicle and engine variant. The selection of a replacement sensor must therefore be based on detailed parameters and guidelines specified by the vehicle manufacturer.

Accordingly, Highway Automotive only supplies replacement NOx sensors that are designed and produced following the vehicle manufacturers’ specifications, and through its product catalogues, it indicates precisely which type of sensor should be used in the vehicle being repaired. In addition, each is delivered individually calibrated and protected against accidental contamination or damage.