What was wrong with the Scania R-Series?

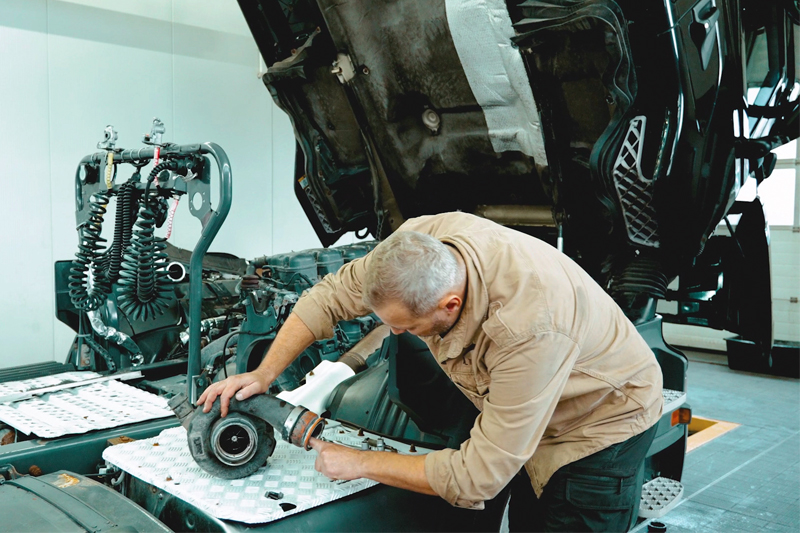

The engineers at Nissens Automotive put the performance back into a Scania R-Series with a new turbo and heat exchanger.

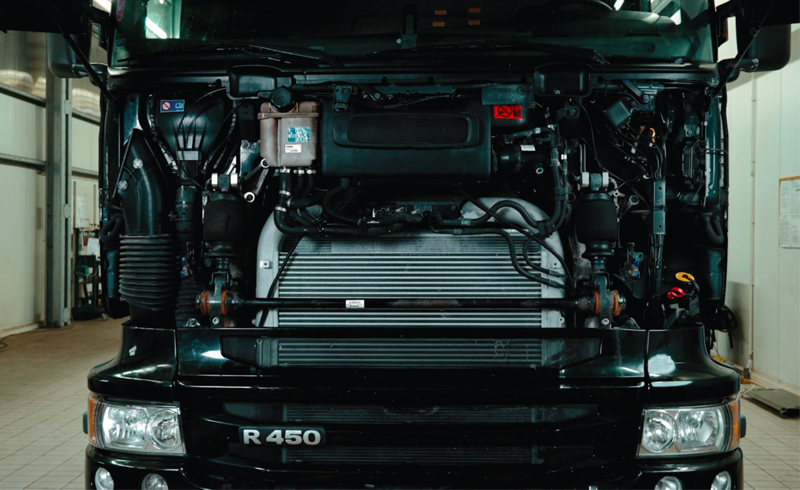

The Scania R-Series is one of Europe’s most popular trucks and one of the most hardworking. But like any long-haul vehicle the miles take their toll. The R-Series model that came into our workshop had several faults, including coolant loss, which the driver noticed during routine checks, a lack of power and as the ‘engine check’ light was illuminated, the engine was operating in limp mode .

The problem with the engine cooling system was quite obvious, as the radiator was leaking, but in the case of the turbocharger system the problem was diagnosed to be the intercooler. However, the turbocharger was also checked and found to need replacement too.

After the removal of the radiator, condenser and the intercooler, removed together as an interconnected unit, it was this last component that was the first to be examined. Signs of oil in its corner indicated a leak, which meant that the turbocharger couldn’t generate enough pressure in the system because some of the air was escaping into the atmosphere. This was why there was an error displayed on the dashboard and explained the engine’s lack of power. So, the intercooler definitely needed to be replaced.

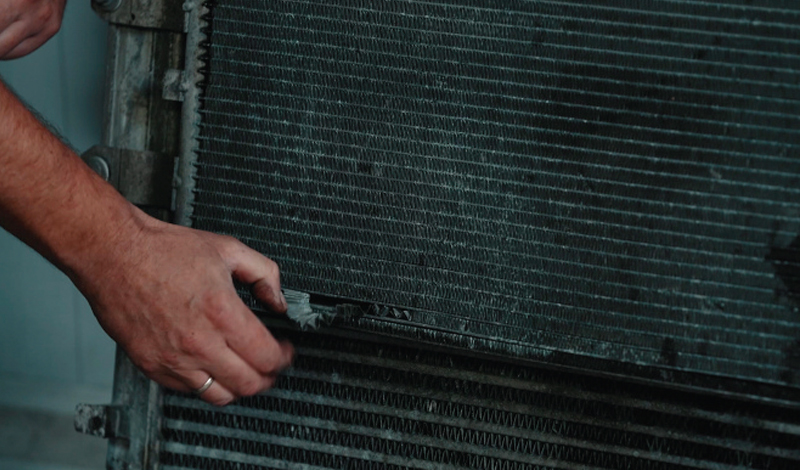

Turning to the radiator, although from the back it looked fine, when viewed from the front, where the intercooler and condenser are mounted, there was a visible leak within the water tank, which was what was detected by the driver, and so again required replacement.

Furthermore, during the removal of the radiator unit, it was noticed that the air conditioning (AC) compressor had at some point been replaced, which meant that the AC system should have been serviced, but if it was, the condenser must have been overlooked because its condition was dreadful.

With the condenser in such a state, the compressor will have been subjected to excessive thermal loads, making it susceptible to damage. As the compressor is the heart of the AC system, and one of its most expensive parts, it is important to check the condition of the condenser every time the system is serviced and replace, if necessary, which, once more, was a requirement in this instance.

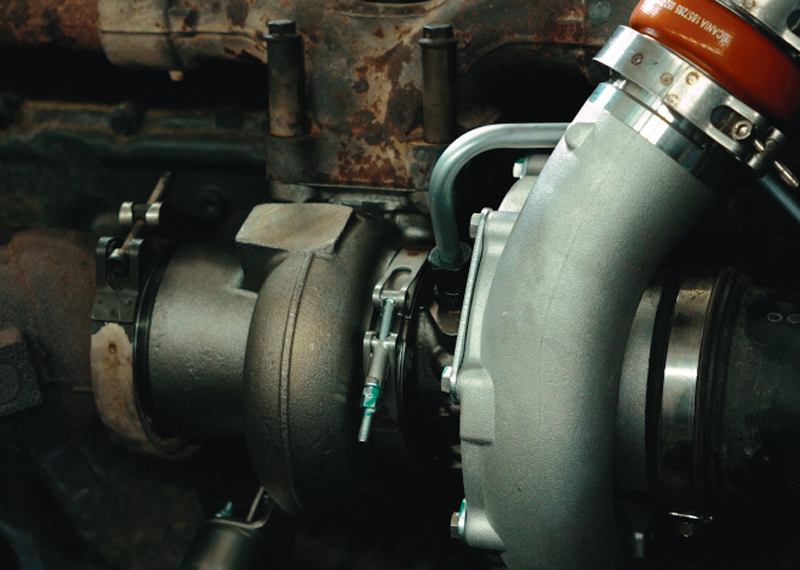

The next job was to look at the turbocharger, which although still operational, had obvious signs of oil visible on the inside and on the surface of the compressor wheel. This indicated blown or broken bearings and seals, allowing the oil to get inside the turbocharger and then be sent into the engine, where it was burnt, so polluting the exhaust gases. Although the turbo was still working, it was also exposed to increased wear in the process and affecting the engine’s condition at the same time, which meant the turbo had to be replaced.

Installation

Although new, the replacement turbo was examined to make sure that it was fully intact and that there was no damage that might have happened during transport. In addition, before its installation all the necessary additional parts associated with the system and directly influencing the turbo and its operation, such as the oil feed lines, were examined. Some people clean and reuse these, but it is strongly recommended by the manufacturer and by turbo system experts, such as Nissens Automotive, to replace them when installing a new turbo.

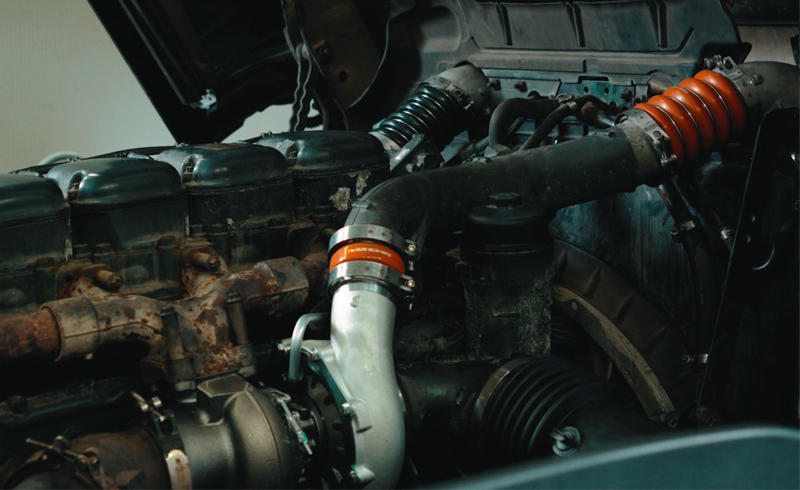

Before fitting the new turbo the area around the turbo, for example the air intake system, was examined. In addition to the obligatory replacement of the air filter, the condition of all the air intake channels and ducts was assessed to make sure that they were free of any perforations, splits or general wear and tear and the joints for leaks. Similarly for the exhaust system, which has a direct impact on the turbo. The EGR valve was checked and the particulate filter examined to make sure it was not clogged so that the exhaust gases discharge properly, otherwise the turbocharger will suffer from excessively high exhaust back pressure, leading to thrust bearing and turbine failures.

Furthermore, the crankcase ventilation was checked to make sure it functioned properly, and its valves were not stuck and the oil separator not clogged. Otherwise, the high pressure inside the crankcase will restrict the free return flow of the oil from the turbo, causing its shaft seal to blow and extensive oil to flood through and be burnt by the engine.

A Nissens Automotive turbocharger includes all the necessary gaskets and ancillaries and also contains a syringe of oil with which to prime the turbo, as it must be pre-lubricated before installation, to prevent it from making its initial start without any lubrication.

The package also includes assembly instructions and a step-by-step guide on how to properly install the turbocharger, which is useful for both experienced professionals and those less familiar with turbo replacement but will assist them to perform a right first time installation.

Handling the radiator, intercooler and condenser, must also be carried out with care, but as with their removal, once joined together, these can be installed as a unit. However, checking the condition of the connections when replumbing them into their respective systems, is vital.

Once the installation had been completed, the oil and coolant obviously also needed to be replaced. Then after starting the engine, a visual inspection was performed to check if the installation had been done properly and to look for any possible leaks. All the vehicle systems were checked and the fault codes reset, before a final test drive and recommissioning the vehicle back into service.

As a final reminder, each component within the engine cooling and turbocharging systems should be thoroughly diagnosed and comprehensively repaired and only premium replacement parts like the Nissens Automotive range of turbochargers, intercoolers and radiators should be used. In short, don’t cut corners when repairing trucks as the results could be costly!

To see a video of the R-Series repair, go to https://support.nissens.com/en/material/repair-of-euro-6-truck.