The importance of year-round aircon maintenance

Keeping commercial cabs comfortable and drivers in good shape is a year-round job. Nissens Automotive looks at what makes aircon work and why maintenance is important.

One of the critical elements of driver safety and comfort is the air conditioning (AC) system. It ensures comfort in the cabin, regardless of the season, by heating or cooling the interior.

Regardless of the type of vehicle, it is highly advisable to ensure the proper operation of its aircon system through regular and professional service and the use of appropriate quality replacement parts. To make sure aircon specialists and distributors stay ahead in the busy climate season, it’s important to prepare sufficiently because both drivers and operators count on their climate system competencies!

Sensitive types

AC systems operate using the thermodynamic properties of chemical refrigerant circulating inside, and thanks to the medium looped inside the system, and the operation of individual components that control its flow and pressure, the system can exchange heat between the medium inside the system and the surrounding elements. In this way, the system regulates the temperature of the air supplied to the cabin by cooling it.

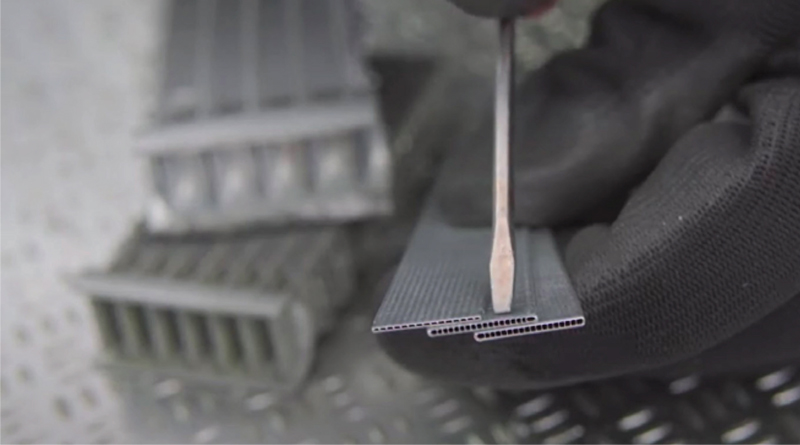

In addition to wear of the elements within the system during its normal use, it can also suffer other damage. The conditions needed for its operation, namely high temperature and pressure inside the loop, and the precise and, in some cases, fragile components, including some mechanical and electrical control parts, means servicing the aircon system is not straightforward. Hence, it requires solid knowledge to diagnose and repair, which starts with the basic understanding that its longevity is very sensitive to the wrong operating conditions.

These factors must be considered when thinking about the upcoming busy service season and beyond, as in many vehicles, the system is required to be in operation all year long. Therefore, for both highly experienced system specialists and those who are just entering the business, it is important to learn how to avoid common issues. For example, wrong service procedures, the use of inappropriate consumables and agents, using poor quality parts, neglecting what might just seem to be light damage such as dirt (inside or on the surface) or leaks, and other system faults, e.g., airflow disturbances, may all lead to severe system issues and the need for costly repairs.

Wide coverage

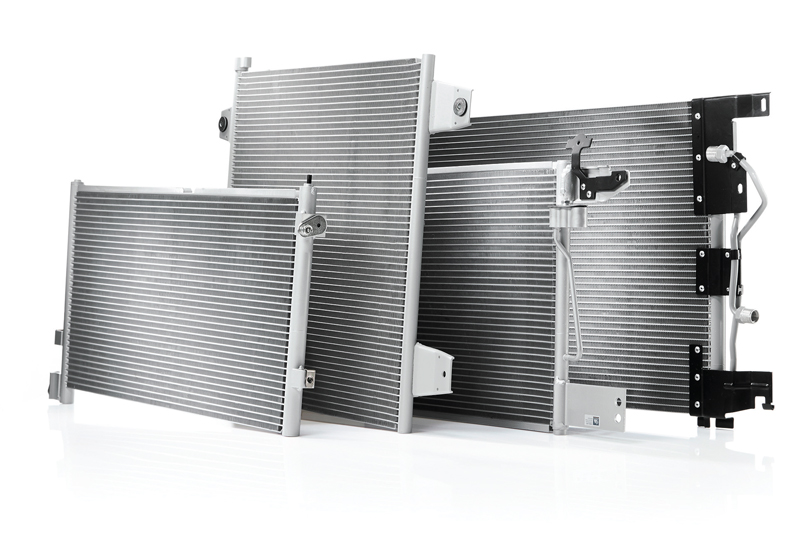

One way to avoid mishaps is to source components from a reputable supplier, such as Nissens. We offer an extensive and competitive range that covers a wide variety of products, and decades of experience in designing, developing, and manufacturing thermal system components for vehicles, and provide aftermarket solutions for many automotive systems. Today, the company’s CV parts programme includes more than 800 part numbers that cater for 4,400 OE numbers, offering excellent truck parc coverage of over 85% within key product lines and Euro 6 applications.

Our CV climate system parts offering consists of eight key AC product lines, encompassing more than 200 items. As vehicle fleets develop and change, so does the range, which continuously expands to best match the most popular applications and address the recent technology evolutions.

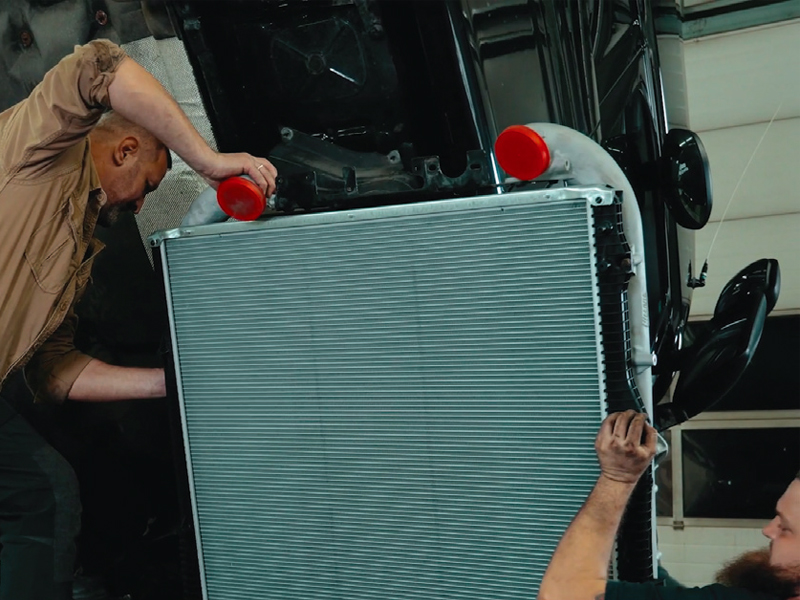

While the range, coverage, and availability of reliable quality parts are obvious, it is also essential to ease the strain on the technicians undertaking the work. So, assembly related features that make the replacement process safer and faster, and technical support from the manufacturer to help avoid common problems are priceless.

All Nissens components are manufactured to the genuine Nissens quality standard, which ensures outstanding performance and durability and easy installation of the part through perfect fit and with additional items included in the (First Fit) set, for example suitable O-rings, mounting screws, or the appropriate oil in the compressor, are inside the product box. In addition, safe packaging and transport protection ensure that sensitive components arrive safely from the warehouse to the workshop.

We also provide a wide range of technical support targeting industry specialists on various levels and technicians can benefit from the using our recognised quality training and technical support material. The expert knowledge portal, for example, includes a broad library of technical tips and service procedures, as well as great tools, such as the oil and gas finder, with hundreds of vehicle makes and models.