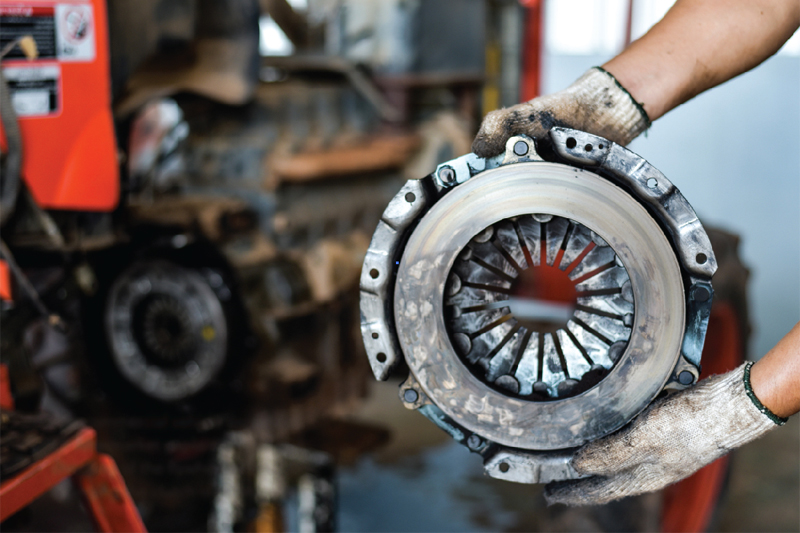

The commercial vehicle experts at ZF Aftermarket explain why careful checking of the flywheel when changing the clutch is so important.

In most commercial vehicle (CV) engines, the flywheel is a massive component. But despite its size, it can wear out: for example, on the starter gear ring or the friction surface. This is because the flywheel is tapered by only a few tenths of a millimetre in order to ensure smooth clutch engagement.

After a clutch change on a truck, if the clutch engage is still jerky and affects the starting behaviour, it may be because the flywheel is worn. Although this component is extremely durable and, therefore, not included in the usual clutch spare parts kits, even this massive component is subject to wear and tear over time.

The friction surface, for example, has a conicity that is barely visible to the naked eye. It is tapered by a few tenths of a millimetre so that the friction disc does not abruptly apply, but instead makes the startup process as smooth as possible.

However, this taper can wear out after long use. If this happens, the frictional connection is established without transition when the clutch is engaged, which leads to the inharmonious starting behaviour, as described above. Incidentally, this jerky behaviour is not only a comfort disadvantage, but can also result in consequential damage to the driveline.

In addition, another point on the flywheel that is subject to wear is the starter ring gear. The engine is likely to be started several thousand times during its service life meaning that the starter pinion meshes with the corresponding ring gear frequently, wearing away the material.

This can result in starting problems. Other criteria for assessing the condition of a single-mass flywheel are local thermal overloads or cracks in the contact surface.

The experts from the Aftermarket Division of ZF, the world’s leading supplier of commercial vehicle driveline technology, therefore recommend that commercial vehicle workshops intensively inspect the vehicle’s flywheel every time the clutch is changed.

It is recommended that the customer replace it at an early stage or at the same time as the clutch if there are any signs of wear. Replacing the component does not incur high additional costs, but can prevent expensive consequential damage.

Key points

- The starter pinion repeatedly meshes with the flywheel ring gear ring and causes abrasion

- The taper of the friction surface can also wear after repeated use, leading to clutch vibration

- Proactive replacement of the flywheel prevents expensive consequential damage