ZF says its mission is to allow vehicles to see, think and act. CVW gets the lowdown on what technology the company has in store for the commercial vehicle segment.

As the push towards zero-emissions transportation accelerates, the CV sector has a critical role to play in hitting the brakes on climate change. With transportation accounting for more than one-fifth of global carbon emissions – and trucks and buses representing the largest contributor – the CV sector must take the lead in making zero-emissions vehicles a viable reality.

According to the International Energy Agency (IEA), the international governmental body overseeing global energy use, emissions from the trucks and buses sector will need to reach a peak within the next few years and then make a rapid decline if we are to hit net-zero scenario milestones.

Urban buses have so far led the way for the sector, with a rapid uptake in EVs. But finding alternatives in heavier truck segments is proving a tougher prospect. Developing viable alternatives to diesel for heavy-duty trucks with regional and long-haul range capabilities, which by IEA estimates account for three-quarters of heavy-duty vehicle fuel consumption, is proving particularly challenging.

Electrify everything

ZF says it is leading the charge to bring new, greener and more sustainable technologies to the CV industry. It foresees a mix of new technologies, specifically a blend of batteries and hydrogen fuel cell systems, emerging as the dominant solution to address the pressing challenge of achieving zero emissions.

Batteries can cater for short and medium-range transportation needs, such as urban commuting, while hydrogen fuel cells can be used for long-range journeys. This hybrid approach takes advantage of the respective strengths of each technology, paving a way towards viable and sustainable zero-emission transportation.

New systems that are suitable for light, medium, and heavy-duty vehicles, and trailers such as all-electric central drives, axle drives, and eComponents are reshaping the thinking around powertrain systems.

CV operators can quickly reap the benefits by integrating electrification technologies into their fleets to generate efficiency savings that electrified power systems can bring.

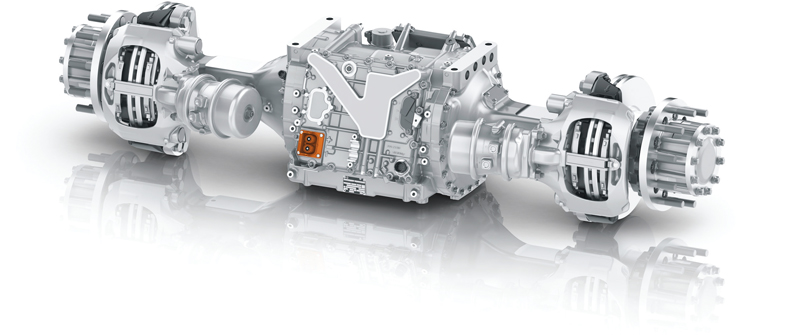

One such innovation that has been developed is the new AxTrax 2. A modular, axle-based e-powertrain system, AxTrax 2 can help manufacturers and fleet operators ease the implementation of electrification for almost all types of CVs up to 44 tons.

First unveiled at the recent Advanced Clean Transportation Expo in Las Vegas, it features a compact design that maximises the available space for batteries while giving manufacturers design flexibility for future vehicle concepts.

Increased integration

It can also be fully synchronised with key vehicle functions, including braking, ADAS, and automated driving systems, to help enhance vehicle safety and efficiency, while enabling advanced digital and telematics systems via CAN bus to communicate and share e-axle system information. Production in Europe is set to begin in 2024, with the U.S. following in 2025.

“With our modular electric drive kit, ZF can provide customers with everything they need to electrify their commercial vehicles from last-mile delivery vehicles up to 44-ton trucks,” explains Winfried Gründler, senior vice president of Driveline Systems with ZF’s Commercial Vehicle Solutions division.

“Consisting of complete axle and central drive systems that, like other ZF electric systems, uses open technology, AxTrax 2 can be easily combined with a battery or a fuel cell system, for example. The kit is complemented by a wide range of eComponents.”

Embracing modular principles, AxTrax 2 can either be integrated into ZF’s full e-powertrain systems or it can provide a ‘mix-and-match’ option for manufacturers to use alongside their own components, taking advantage of synergies and common interfaces.

Concepts and innovation

ZF is also keen to harness a dynamic commercial vehicles sector by enabling new entrants to employ its systems and components as well as its advanced engineering expertise to bring their new concepts and innovations to market.

For example, ZF’s recently announced collaboration with British truck maker, Tevva, has helped the company integrate ZF’s regenerative electronic braking system (EBS) for its new zero-emission 7.5-ton truck. The EBS system enables the truck to capture up to four times more energy than a traditional air brake system, further optimising the range and performance of the truck.

“Our broad product portfolio, including ZF’s standardised EBS, enables faster time-to-market for new, innovative market players such as Tevva,” says ZF’s Heiko Eggers, head of commercial vehicle EMEA application engineering for braking and ADAS. “Tevva’s commitment and agile engineering expertise allowed us to meet our stringent safety requirements and complete our project. We look forward to seeing the first trucks on the road.”

Collaborations such as these help accelerate the development of the technical solutions that will drive the industry toward the new future.