Tips to help diagnose, fix and test the AC system

Diagnosing, fixing and testing the aircon is a routine matter normally but occasionally a bit more troubleshooting is needed. Auto Air Gloucester offers a few cool tips to get you started.

‘The aircon isn’t blowing cold enough’ is probably a phrase repeated time and time again across the UK’s workshops as disgruntled customers complain about the sweltering conditions in their cab. Diagnosing why a vehicle’s AC isn’t blowing cold enough can be tricky. As you know there are many components that form the AC system and any of them can cause poor performance.

A common cause can be low refrigerant levels. Even a slight loss of refrigerant, possibly due to leaky O-rings or seals, can affect the temperature through the vents. A sign of low refrigerant is the compressor short cycling (clicking off and on). Locating refrigerant leaks can be difficult even for you professionals. Oil stains on the condenser, compressor, hoses or fittings are a good clue to the whereabouts of a leak but remember to check the service ports where Schrader valves, caps and O-rings are located.

Check to make sure the cooling fans are running when the AC is operational. Leaves, dirt, debris or bent cooling fins blocking air from passing over the condenser and/or evaporator will increase the refrigerant pressure – raising the temperature and resulting in poor performance.

Symptoms and diagnosis

The compressor can be a shared cause. Check to make sure the clutch assembly is engaging. With the engine running, the blower fan on max and the AC controls set to the coldest temperature the clutch should be spinning. You may hear a click or a change in the engine when the clutch engages. If the clutch is not engaging the refrigerant is either very low, the clutch itself has failed or there could be an electrical problem.

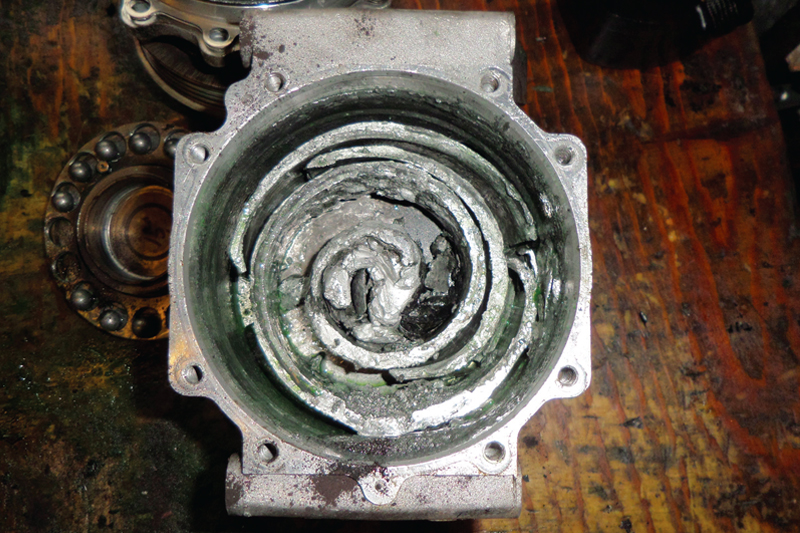

Also check the accumulator / receiver drier where desiccant bags are used to absorb moisture running through the AC system. Moisture can enter a leaking system and react with refrigerant to form a corrosive sludge. As a result, oversaturated desiccant can ooze into the AC system, blocking every AC component.

Contaminated refrigerant from corroded internal parts can also block components but most importantly will eventually damage the compressor. This is why it is essential to flush the system every time it is opened up to the elements.

Then again, it could be something more complex such as any number of fuses, pressure/temperature sensors or switches that can affect the AC systems operation and cooling performance. Check all electrical connections are clean, tight and secure. Remember the engine control module which can keep the AC from turning on.

There is one component which is often overlooked when diagnosing an AC system problem. A dirty cabin air filter can lead to poor AC cooling output, but it is easy and inexpensive to replace. It’s worth telling the customer to run the AC 10 minutes a week, even in the winter, because it helps circulate refrigerant oil and lubricate the compressor and condition the O-rings/seals.

Remember refrigerant freezes skin quickly and can be painful so take care. Use specialist tools and equipment to accurately diagnose the problem, safely reclaim and recycle refrigerant and make sure your repairs to keep your customers cool while driving.