High-powered abrasive tools can have ill effects on a technician if safety processes are not in place. Mirka, the surface finishing technology specialist, explains what these dangers are and how best to prevent them.

Over the past decade or so, there has been a significant change in the way tools have been made to meet the needs and requirements of the user. This has led to increased investment in R&D by tool manufacturers in order to design and develop durable products that can deliver an efficient overall process and a high-quality finish on a variety of surfaces, while protecting users against the associated dangers, particularly Hand Arm Vibration Syndrome (HAVS) and dust particle inhalation.

Hand Arm Vibration Syndrome (HAVS)

HAVS, which affects the blood vessels, nerves, muscles, and joints of the hand, wrist and arm, is becoming a bigger issue for workers, as it is a condition that cannot be seen or noticed until it is too late. The reason for this is because every worker is different. Each individual has his or her own tolerances for the amount of vibration they can handle. They may also fail to realise that there’s a problem until they try a different tool, or if they do not use their own one for a while.

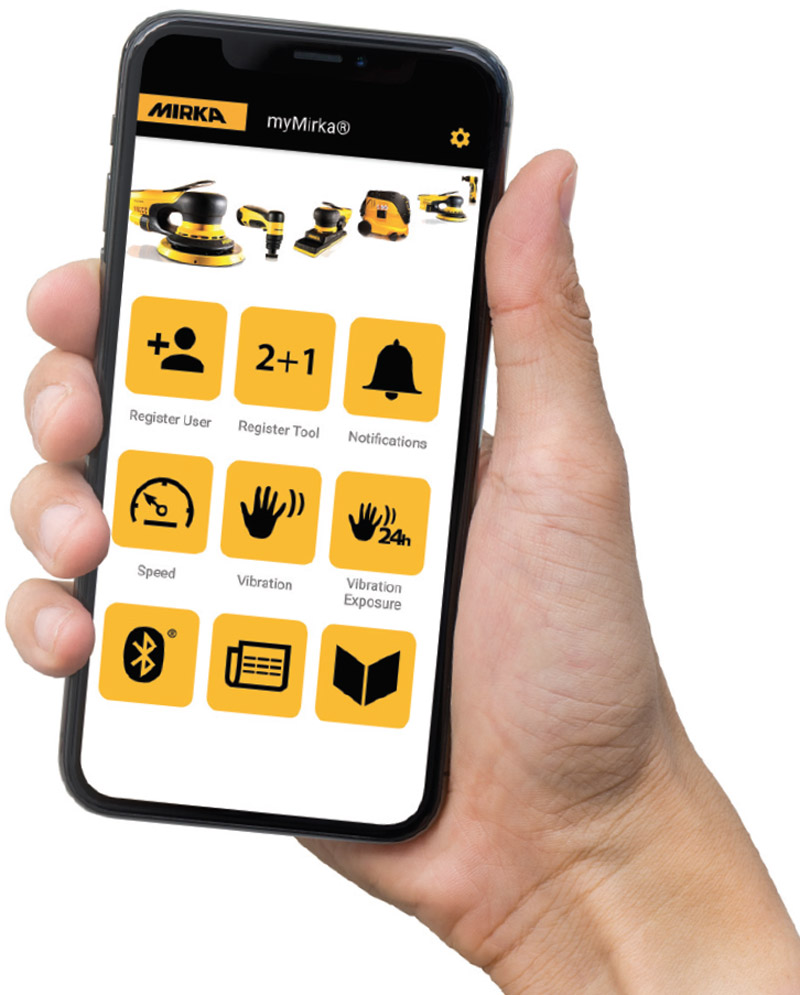

For Mirka, the fight against HAVS starts with putting the emphasis back on the user. To these ends, the company has introduced myMirka app (applicable in the Bluetooth enabled tools within the Mirka product range). The app provides the end user with the vibration levels from the tool on a colour graded scale, and advises on how to lower the vibration if required.

Additionally, the speed the tool is being used at can be visualised in a real-time graph. Furthermore, there is an in-app purchase that tracks the daily vibration levels in relation to European standards for a comparable scale of the pressures that joints are subjected to on a daily basis. This last aspect allows the business to see how the tools are being used and potentially assists in the implementation of measures to protect the workers. The app is available to download through Google App and Apple App store.

Dust particle inhalation

Extraction systems may seem like they take up a lot of space but dust particles can be a major health issue for employees and could possibly lead to respiratory problems. This is why an increasing number of businesses or single users are investing in systems to allow them to work in a dust-free work environment.

Laboratory tests have shown that without dust extraction, dust in the air per kilogram of sanded material is over 200g per kilogram, and dust on surrounding surfaces is almost 800g per kilogram. These may not seem like large quantities but when they accumulate over a long period, they could potentially turn into both a fire and health hazard for the business.

However, investment in a suitable mobile extraction system is not a short-term injection of a business’ cash. Instead, it should be viewed as a long-term commitment, so that it can provide an effective solution for a cleaner work space, a reduction in prepping and tidying up at the end of the day, and the potential dust contamination of other tools and surfaces. The smaller systems are more often used in workspaces because they are equipped with a local air supply and extraction, and are easy to move and store.

Dust extraction tips

- Make sure the fleece bag in the mobile extraction unit is not full and does not have any rips or holes. If it does, replace it

- Periodically remove and clean the motor filter. This can be done by placing it in a bag and gently knocking the dust out of the filter. Or better still, use another vacuum or extractor to clean the filter. Once it is clean, replace the filter in the machine

- Make sure the seal between the tank and upper section of the extractor is clean and not damaged.

Tool vibration tips

- An increase in vibration can cause damage to the tool, so be aware that any variation in pad weight, other than when using P180 paper discs, can cause the machine to vibrate more

- Always use a genuine Mirka backing pad on Mirka tools, as it has been specifically designed for certain machines (a DEROS/PROS 150mm backing pad is engineered to weigh exactly 130gms). However, if you use a generic, non-Mirka pad it may alter the vibration of the tool and, in turn, cause damage to the bearing and other aspects of the tool. Mirka tools returned with non-Mirka pads fitted are not covered by the Mirka warranty

- If you intend to use an interface pad (5mm/10mm), you should remove the backing pad and insert the grub screw that comes in the box with the tool into the remaining threaded hole beneath the pad. This will counter balance the weight of the interface pad and reduce the vibration of the tool when in use

- The grub screw should also be used if coarse or heavy weight discs (P40/60, etc.) are on the sander

- Using a pad saver will protect the backing pad from wear. If P80 to P120 discs are used with a pad saver, Mirka recommends the insertion of the grub screw

- Ensure that the product is regularly serviced for optimum performance.