Millers Oils provides some advice on how to meet the more stringent emissions levels and run a fleet more cost-effectively.

The introduction of roadside emission checks by the DVSA has certainly had an impact on the industry, highlighting a wide range of ‘fixes’ that have been introduced to some vehicles in order to get around emissions levels.

The DVSA found everything from devices added to trucks that provide false road emissions data to removal of diesel particulate filters, but their main rationale has been to cut operating costs. The DVSA is continuing to focus on illegally operating trucks and is searching for emission cheat devices, passing any evidence found on to the Traffic Commissioners for Great Britain – who have the power to remove an operator’s licence.

But operators do not need to take such extreme measures to run their fleet costeffectively and meet the more stringent emissions; as Martyn Mann, Technical Director at Millers Oils and President of the UK Lubricants Association, explains: “At Millers Oils we work tirelessly with our customers to tackle the challenges of the modern haulage industry, developing products that meet the latest legislation and specifications without compromising performance. Eclipse diesel treatment is an example of a product that delivers value for hauliers whilst aiding compliance with the ever more stringent environmental legislation.

“The treatment works primarily by cleaning and protecting the injectors. If the injectors are blocked or dirty, you don’t get the right mix of air and fuel inside the engine, so no matter what the quality of the diesel, the MPG of the vehicle will decrease, and the amount of harmful emissions such as carbon monoxide and NOX will increase. By simply adding 500ml of Eclipse to each 500L tank of diesel, users also benefit from increased engine power – a boost of up to four Cetane Numbers, as well as improved engine smoothness and noise reduction, without altering fuel compliance to BSEN 590.”

Following the usage guidelines, even trucks that have previously received Notification of Refusal under the smoke test have been resubmitted after Eclipse application and passed with flying colours.

Fuel savings can also be improved with use of Eclipse; in a recent case study a leading UK haulage company saw a reduction in fuel consumption of 6.1%, translating to a saving of 18,000L of fuel per year and a CO2 reduction of 48 tonnes per year across their fleet of 290 vehicles.

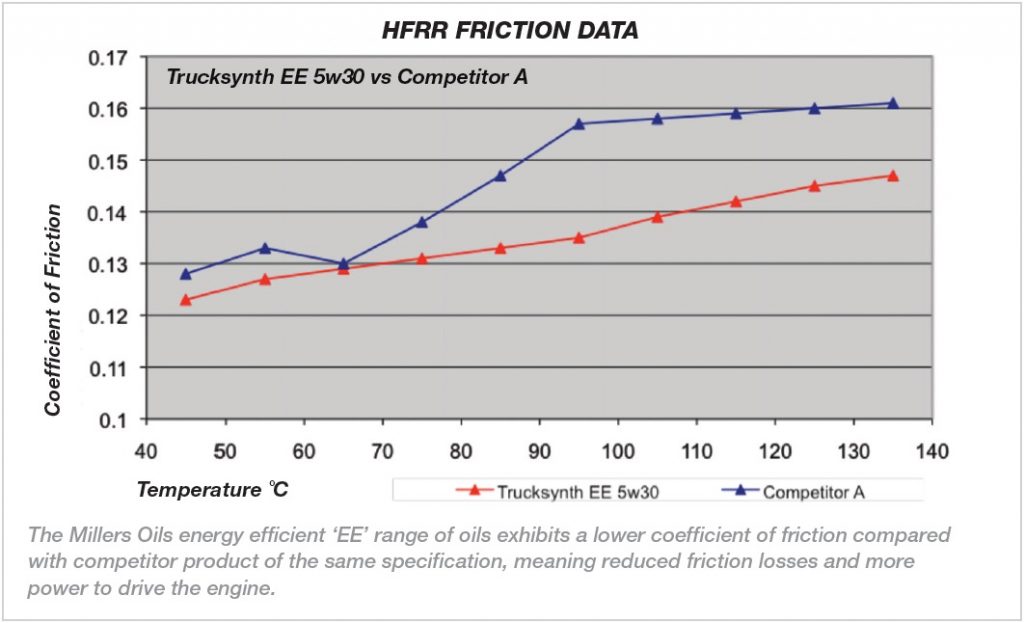

A choice of lubricants also makes a difference for fleet managers looking to manage their operating costs and is an often unconsidered element in the equation. The Millers Oils energy efficient ‘EE‘ range of oils takes the low friction technology they developed for the race track and applies the concept to their truck engine oils. By minimising the friction losses in the engine whilst maintaining an optimised oil film thickness, their high performance oil not only meets the requirements for modern extended-drain intervals but also offers improved fuel economy and a reduction in overall running costs.