Roger Thorpe, BPW Engineering Manager, explains the technical workings of the company’s self-steering axle.

The BPW self-steering axle contains a unique design of centring device, which is a major contributing factor in its success in the UK market and, in particular, within running gear solutions for longer semi-trailers (LSTs). But how does it work? The principle operation is quite simple, and is based on the principle of the castor. This relies upon lateral forces applied to the wheels when the trailer is turning.

If, for example, the trailer is travelling forward and the driver turns to his right, the trailer will pivot on the effective bogie centre which, on a three-axle trailer, will be about the centre of the rear bogie. This will cause the rear of the trailer to move to the left, and the friction between the road and the tyre will create a force which pushes the wheels on the steering axle to the right with respect to the rear of the trailer. This will cause the wheels on the steering axle to turn towards the left and follow the front of the trailer around the right-hand turn.

It is worth noting that, if a trailer is fitted with three rigid axles, then the effective bogie centre line is the centre axle. But, when a self-steering axle is fitted to the rear position, then the effective bogie centre line is mid-way between the first and second axle. This effectively shortens the wheelbase of the trailer and increases the forward manoeuvrability.

Anyone who has observed a castor moving at a steady speed across the ground will know that it exhibits a ‘shimmying’ action. This is an oscillation about the vertical centre line of the pivot. The cause of this is the constant hunting between the turning force (the wheel on the ground) and the restoring force (the forward motion in an undamped castor).

Obviously, this cannot be allowed to happen in an axle system mounted to a trailer, as this will cause instability when driving and contribute towards tyre wear (the avoidance of which is one of the benefits of using a self-steering axle).

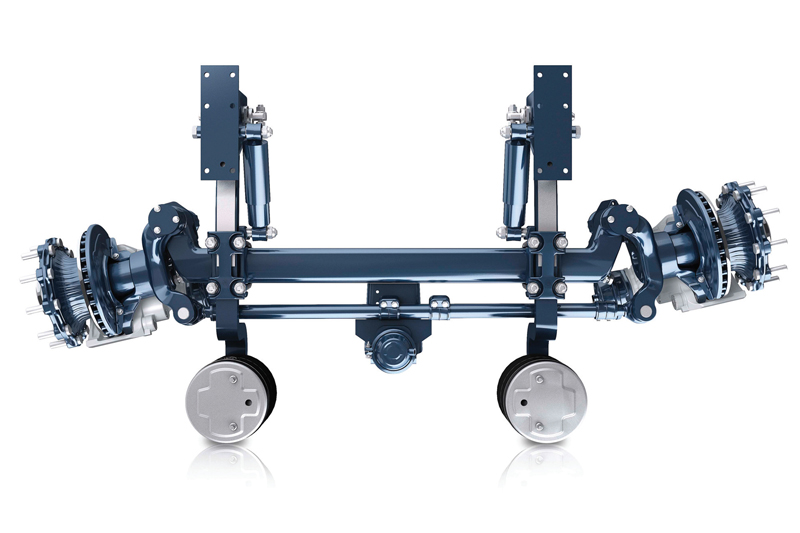

The BPW system relies on ‘corrugated washers’ – two nested circular plates, each with four cam lobes formed into them – in order to combat shimmying. As the axle steers, the cam faces rise up against each other. This action constantly tries to centre the steering back to the straight-ahead position.

The trick is to design the slope of the cam faces so that the restoring forces generated balance off the turning forces, and prevent the oscillation which causes the shimmying. The benefit of this system is that the restoring force increases with the load on the axle due to the weight on the corrugated washers. The turning forces also increase with load and, thus, the two are always balanced. There is no need for systems of air bellows or dampers.

Of course, in reverse, the system will not work, as the pivot point of the castor action will now be to the rear of the hub centre line, and the self-steering system will be unstable. A pneumatic locking mechanism is provided – fitted to the track rod – and this is normally activated by an electrical signal taken from the trailer reversing lights.

The advantages of this system are that a 10% saving on tyre wear over a tri-axle bogie can be achieved. The unique, load-sensitive anti-hunting device adds further to this saving, whilst ensuring that the axle is not burdened with heavy and bulky damping mechanisms.