Continental answers tyre regrooving FAQs

Regrooving tyres is an accepted way of extending life and saving money, but it should be done safely and effectively. Here, Tomasz Wojciechowski, technical specialist engineer at Continental addresses some of the most commonly asked questions.

As one of the leading tyre manufacturers we are always being asked about regrooving, the benefits and pitfalls. One piece of advice we always give commercial vehicle and fleet operators is to ensure they are carrying out tyre regrooving safely and effectively. Earlier this year, we produced a five-part series of tyre safety and advice videos, aimed at supporting technicians, drivers and business owners with key maintenance topics. It’s well worth a look and the link is at the bottom of this article.

First though let’s consider a few important operational factors that businesses should consider when regrooving a tyre. Is it safer to not regroove a tyre? Regrooving can be a safe, cost-effective solution that will extend the service life of a tyre. The problems begin when regrooving is not done correctly. All too often, we encounter tyres that have been cut too deeply or were in a poor overall condition to start with. Not only could it influence the tyre’s performance and durability, as well as potentially being illegal, but it also ultimately negates the benefits of regrooving as it requires a replacement tyre.

Operators shouldn’t be afraid of regrooving a tyre that is in good overall condition and is approved to be regrooved by the manufacturer. All of Continental’s truck and bus tyres, for example, can be regrooved. Done well, regrooving will help operators to maximise the service life of their tyres and help them to achieve the lowest overall driving costs for their fleet. If it’s a feature that’s included, it’s one that you should consider using.

Is every used case appropriate for regrooving?

Although there’s nothing to stop you regrooving tyres for your business, we do find that the longevity, and therefore cost effectiveness of using a re-cut tyre, is impacted by the application. Typically, trucks operating off-road on construction sites or in mining and aggregate transport respond less well to regrooving. That is because the tyre is unlikely to last as long as a truck covering mainly motorway and A-road miles.

When it comes to trailers, we would suggest that you avoid using a regrooved tyre on the rearmost axle. Often these tyres are dragged laterally when the trailer corners heavily, which isn’t optimal for regrooved rubber. It doesn’t mean that the tyre cannot be used, however. You could perhaps look at swapping the regrooved tyre onto the first or second axle.

Are there any common regrooving errors?

Cutting too deep is a common regrooving error. You should measure the tread depth in various places around the circumference before you start regrooving. Always ensure that you’re cutting from the shallowest part to reduce the risk of damaging the belt. If you do, the tyre must be discarded. Just like the brake discs on a car that hasn’t been used for a few days, moisture can quickly cause the steel cords of the tyre to begin to rust, which could affect the tyre’s durability.

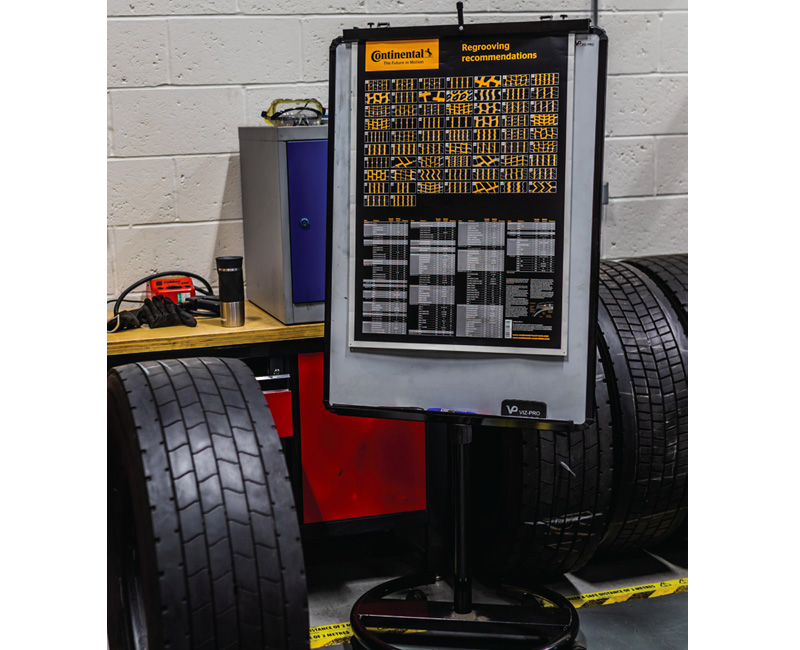

All too often, we also see evidence of technicians getting creative with their own tyre tread patterns. Tyres that are approved for regrooving will have a regrooving guide, specifying where the cuts should be made and to what depth. In our technical data book, we use clear yellow lines to demonstrate where the grooves should be cut. Making your own tread pattern by cutting every sipe or through the tread block may not only weaken the tyre but might also make the tyre unroadworthy.

How can I learn the skills needed to regroove a tyre?

Continental’s UK-based in-house tyre training school, the ContiAcademy, offers tyre technician training courses that help delegates learn all of the necessary skills required for safe and effective tyre husbandry. To find out more about the training courses offered at ContiAcademy call 01788 566 240 or email administrator.technical@conti.de.

![Bosch outlines ESI[tronic] workshop software](https://cvwmagazine.co.uk/wp-content/uploads/2025/07/Bosch-ESItronic-25-165x109.jpg)