Commercial vehicles are more technologically advanced than ever before, but with that comes challenges for workshops. Brett Edkins, Technical Manager at Eclipse Diagnostics, explains how to identify and correct an emission fault on a Wrightbus Streetlite Euro VI.

Identifying faults on many modern commercial vehicles is becoming increasingly difficult as the technology employed by manufacturers becomes more and more advanced. This step-by-step analysis of the emission fault on the Wrightbus Streetlite Euro VI model shows how the Eclipse Jaltest package is becoming the go-to diagnostic solution for the coach and bus industry.

1. The problem

In this example, a defective Wrightbus StreetLite has been taken out of service due to the emission (MIL) warning light being on the dash and the vehicle is in “derate” (reduced power mode). With many possible causes for the MIL lamp being illuminated, an engineer must investigate the antipollution ECU (ACM) using Jaltest diagnostics.

2. Initial assessment

Firstly, make an initial diagnosis of the ACM to check whether any logged faults, present or historic, can assist in the possible cause of the emission problem – these are listed in the diagnosis memory.

For this example, one active fault is detected by the ACM: ‘161100’. This means the plausibility check of the Adblue system produces excessively high values. Many things can cause this fault code to become active; from an Adblue blockage to a failed component.

3. Jaltest analysis

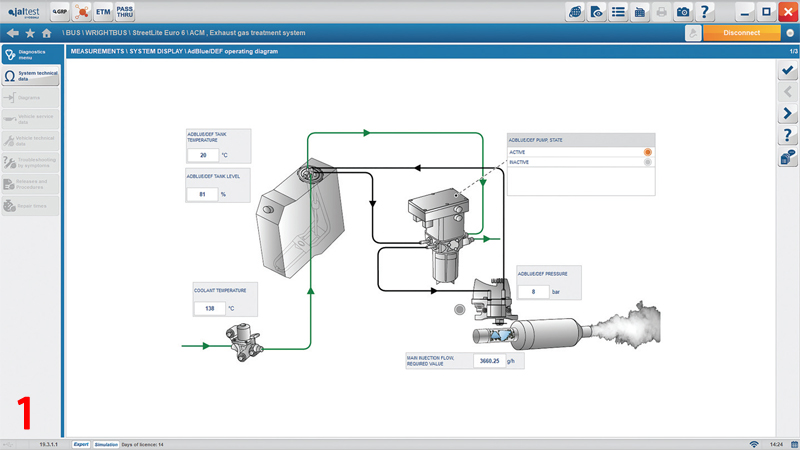

Using the Jaltest software, select measurements within the ACM and check all the live data to ensure all sensors give plausible values. As shown in the image below, Jaltest can display live readings from the ACM. Here, all sensors and components are giving a plausible value, so no issues are currently obvious.

4. Check the ACM functionality

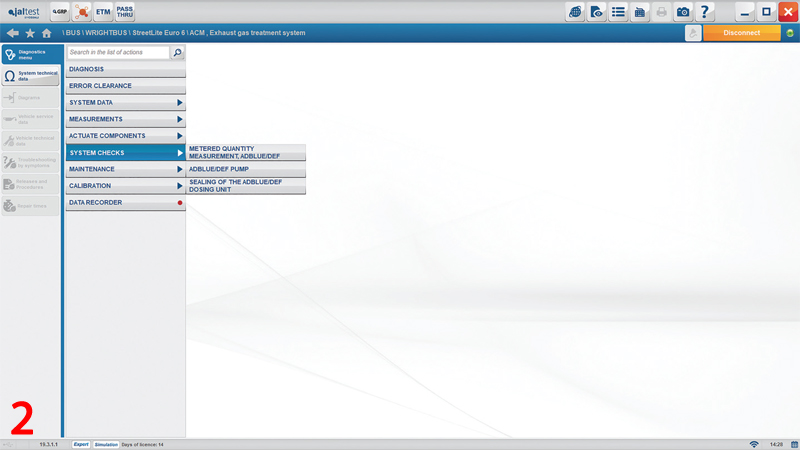

One key system check that helps diagnose this specific error is the metered quantity measurement Adblue/DEF. This test will check all the stages that the Adblue system goes through during normal operation, from the initialising of the system to the dosing of the Adblue out of the metering valve.

The Jaltest software guides the user through how the vehicle needs to be set up so it can perform the test, all the way to exactly how much Adblue should be injected during the test. For example, the metering valve shows only 100ml of Adblue was injected into the calibrated container, when the reading should be between 160-240ml. This highlights a possible blockage within the Adblue circuit.

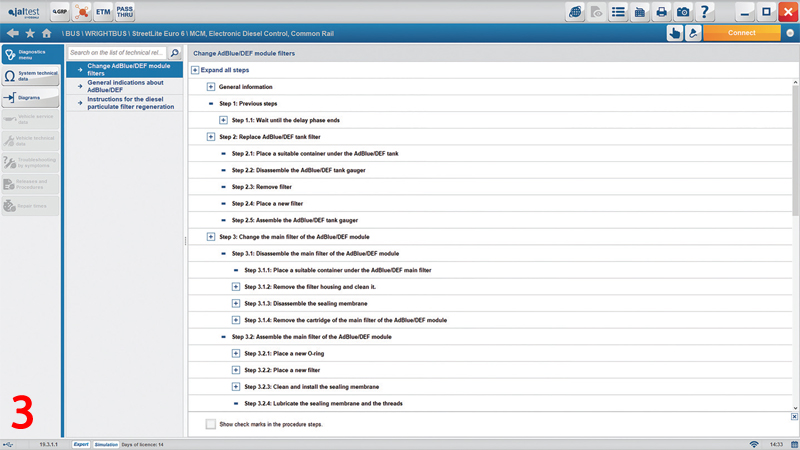

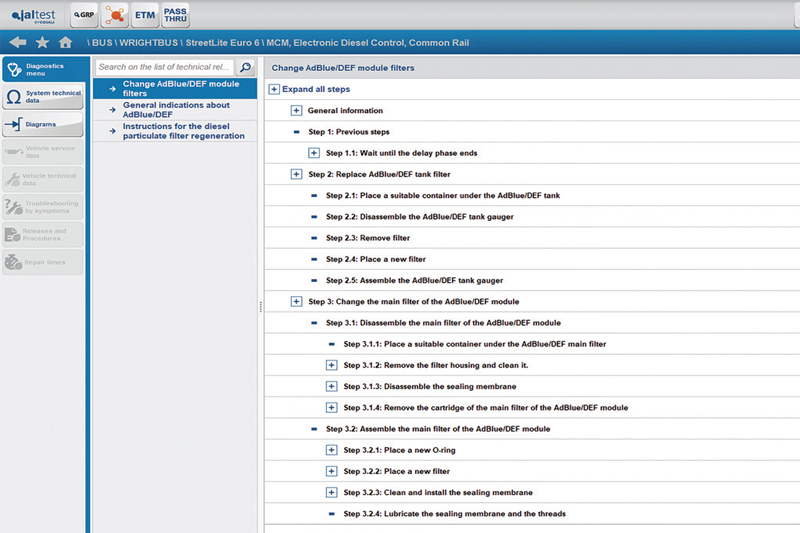

This problem can arise for vehicles that have had no service carried out on the Adblue system, so it is important this is not ignored. Replacing the filters will fix this problem, and Jaltest provides a step-by-step guide to help engineers navigate the procedure.

Clearing down the fault

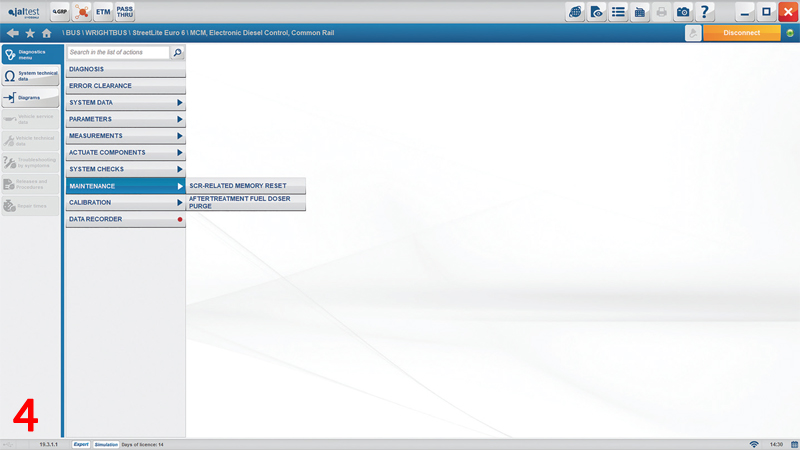

In this example, once the filter has been replaced, another quantity measurement of Adblue/DEF is required to ensure the problem has been correctly resolved. This time, the dosage of Adblue will be set out by Jaltest, however, the previously-generated fault code will remain active until the SCR-related memory reset – found in the engine ECU (MCM) under the maintenance tab – is carried out.

The Jaltest software provides a plethora of features to easily identify faults and possible causes, which are then able to inform the user on how to rectify the problem. Once an issue is resolved, a technician can validate the repair and clear down the fault with minimal downtime and expense.