Brett Edkins, Technical Manager at Eclipse Diagnostics, explains how to identify and correct a brake fault on a MAN TGS Euro VI.

An MAN TGS Euro VI has an EBS 5 (electronic braking system) red warning light on the instrument panel and is failing to clear. As a result of this, the vehicle had to be brought into the workshop; the engineers can use the Eclipse Jaltest diagnostic tool to help identify and rectify the fault within the vehicle.

Initial assessment

The engineer will firstly make an initial diagnosis by carrying out a diagnosis scan on the EBS 5 braking system with the Eclipse Jaltest diagnostic tool. This will allow the engineer to look at the fault codes in the brake ECU whether they are present currently or historically in the diagnostic memory. These fault codes may be able to assist in finding what’s causing the brake warning lamp on the dash.

In the EBS 5 ECU, there is one active fault showing. This fault code is 3201 FMI 5, which is referring to a short circuit on the rear axle left wheel speed sensor. This fault could be due to a wiring fault with the wheel speed sensor, the wheel speed sensor itself being defective, or it could be due to the modulator or modulator wiring being defective.

Jaltest analysis

The Jaltest software can take the fault analysis on the vehicle right down to the component, as well as being able to show the necessary wiring diagrams, operation diagrams, and measurements for the specific vehicle.

So, in this case, the engineer will be able to access fault code troubleshooting for the fault. This will allow them to follow step-bystep instructions on how to diagnose the fault and repair it. The engineer will also be able to carry out system checks and also view live measurements to look at what each speed sensor is reading for speed and voltage.

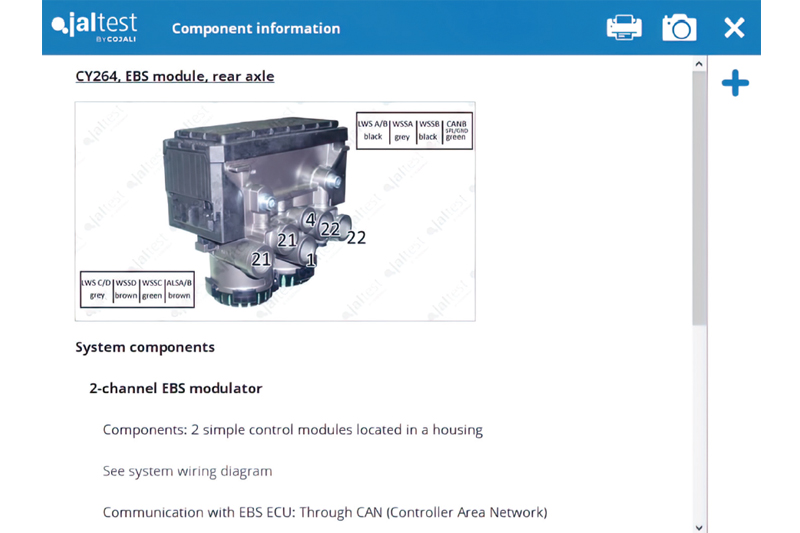

If the fault requires wiring to be checked, the engineer will also have access to configuration specific wiring diagrams and component information so they can check they have appropriate readings for the sensor in question.

Correcting the fault

First of all, the engineer would carry out step one of the fault code troubleshooting and that is to carry out the wheel speed system check to ensure all sensors are reading correctly by taking on a road test and getting someone else to look at the readings. In this case, the rear axle left wheel speed sensor didn’t have a reading.

The next step would be for the engineer to carry out step two of the troubleshooting, which is to inspect the air gap between the sensor and the tooth wheel and then check wiring back to the modulator. This can all be found with the Eclipse Jaltest diagnostic tool component information and also the wiring diagrams.

In this instance, after checking the wiring and air gap to manufacture specifications, the engineer found the sensor was in a nondefective order; to look further into this fault the engineer could use their ETM (Electronic test module).

The ETM plugs directly onto the modulator and, with this tool, we are able to test all the internals of the modulator and carry out a test to check all components on the modulator. The engineer has plugged the ETM into the modulator and the engineer will then be able to carry out a diagnosis and also carry out an end-of-line test.

This test will check all components and then pass or fail the modulator. When the engineer carried out this test, they found an internal fault within the modulator that was causing the wheel speed sensor not to read.

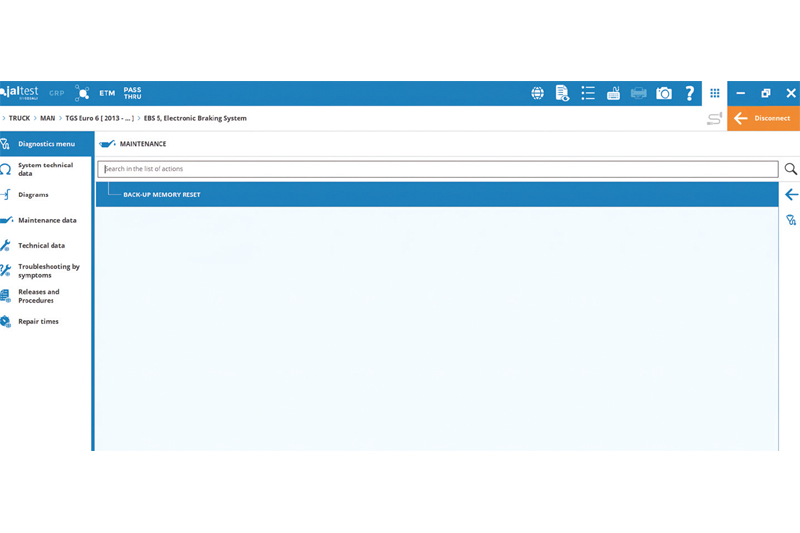

Once the engineer had found the internal fault within the modulator, they were able to replace the modulator for a new one. After replacing the modulator, the engineer will have to carry out the back-up memory reset; this has to be carried out as it will clear dynamic failures within the ECU.

Dynamic failures can be associated with critical elements for vehicle safety and cannot be erased from the failures memory with the normal error clearance.

Eclipse looks after its customers

If this was the first time that the engineer had carried out the procedure then the industry leading Eclipse Vehicle Technical Support service is available to assist. This unique service is offered by Eclipse to all customers and can either assist the engineer in the problem solving process or utilise the remote assistance service.

Every Eclipse Testpad Extreme Pro PC is installed with Eclipse Assist software, which allows the Eclipse Technical Support team to remotely access the customers Eclipse Testpad Extreme Pro PC via internet.

The team, with the customer’s agreement, can access the customer Testpad and assist with vehicle related support. This service allows the Eclipse Specialist to virtually sit next to the customer and see what the customer can see on-screen, whilst taking control.

Eclipse has developed its business around the core philosophy of customer support from when the system is first purchased and throughout its life. That support begins with the software, which is updated three times a year to reflect new models and more information as it becomes available, and continues with the Eclipse support services.

A range of features and services are available, including a comprehensive training package that also includes full training programmes held at the Eclipse Training Centre and cover from the Technical Support Service.

About Eclipse

Eclipse is the largest supplier of multibrand diagnostic products in the commercial vehicle aftermarket, with its innovative Eclipse Testpad Extreme Pro running Jaltest software helping many businesses to improve vehicle and machinery performance.

There are more than 3,000 Eclipse Jaltest packages in use covering a wide range of commercial vehicles at customer locations, both in the UK and internationally.

Identifying faults on many modern commercial vehicles is increasingly difficult given the rising levels of technology employed by manufacturers across all aspects of the vehicles including trailer units.

This increasing technology imbedded in vehicles means that users are having to adopt increasingly sophisticated equipment to enable their engineers to maintain performance and effectiveness in the workshops and when out on remote call-outs.

The Eclipse Jaltest package has all the requirements to address the technological advances and as an example, the analysis of an MAN TGS Euro VI model shows how the Eclipse Jaltest package is becoming the go-to diagnostic solution for the commercial vehicle industry.