Hartridge discusses some of the health and safety considerations when undertaking a DPF clean.

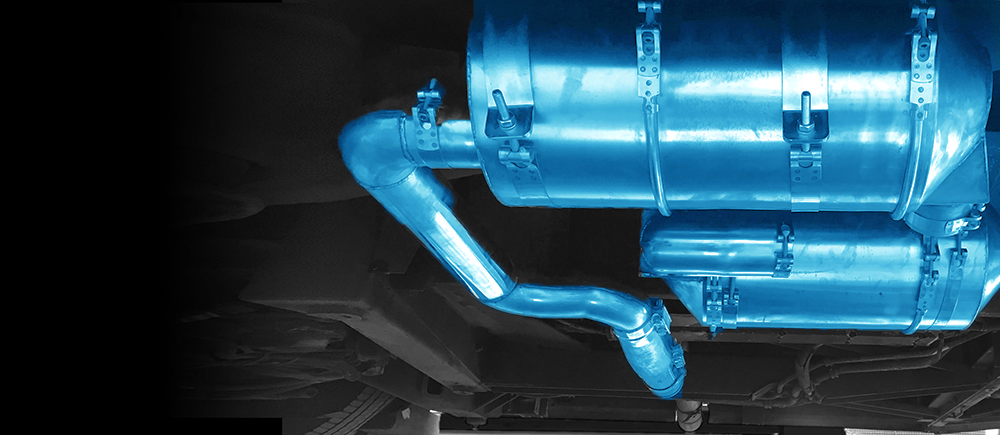

An exhaust system of a heavy duty vehicle requires specialist management and particular consideration for safe handling of components which could be extremely hot or contaminated. It is easy to forget that the soot and ash trapped inside a diesel particulate filter is a highly toxic cocktail of ‘matter’ that has been purposefully prevented from being jettisoned into the atmosphere along with the exhaust gas from diesel engines. If it serious enough to be a legal requirement for vehicle manufacturers to ensure that the public are protected from breathing in particulate matter (PM), then it follows that it is equally important to do the same for workshop staff when they are emptying out a DPF.

Deadly concoction

The California Air Resources Board (CARB) in the USA has led the way globally. They were ahead of the federal government, to implement a DPF programme after a study conducted in 1998 identified PM as a toxic air contaminant. Then later in 2012, their research on the impact of PM on health in California identified that around 70% of the risks associated with air-related cancer causes could be attributed to diesel emissions. The worst of the diesel emissions particles include elements identified as known carcinogens by the International Agency for Research on Cancer (IARC).

There are videos online that helpfully exhibit DPF cleaning with airlines and high pressure water, unfortunately, these demonstrations are happening without any kind of containment and the operator is being exposed to unacceptable levels of PM. Once the PM has been removed from the safe container of the DPF it can easily become airborne because the sizes of the particles are so miniscule. Since it is reintroduced to the environment it should be regulated accordingly as a pollutant; given the very real implications to an individual’s health.

Duty of care

Where exhaust emission treatment technology is responsible for improving vehicle emissions; little has been reported about the health and safety risks associated with working with DPFs. It is central to the efficient operation of a DPF to remove the compact soot and ash that amalgamates over time and which can cause premature failure of the DPF. While DPF servicing and maintenance must to be done, the health and safety measures applied to it can be tailored to the task at hand.

In the United States, the Environment Protection Agency (EPA) has stipulated that any activity that removes PM from a DPF is classified as generating hazardous waste and take effective measures. While there is no specific health and safety based legislation in the UK or EU regarding the handling of PM, it is recognised that any business that potentially exposes employees to PM must take the practicable steps to treat it as a hazardous substance, dispose of hazardous waste, and adhere to measures to mitigate exposure to their employees. Once airborne the PM is likely to remain there long enough to make the working environment hazardous unless the correct personal Protection Equipment (PPE) is used.

In the United States, the Environment Protection Agency (EPA) has stipulated that any activity that removes PM from a DPF is classified as generating hazardous waste and take effective measures. While there is no specific health and safety based legislation in the UK or EU regarding the handling of PM, it is recognised that any business that potentially exposes employees to PM must take the practicable steps to treat it as a hazardous substance, dispose of hazardous waste, and adhere to measures to mitigate exposure to their employees. Once airborne the PM is likely to remain there long enough to make the working environment hazardous unless the correct personal Protection Equipment (PPE) is used.

Hartridge says its interpretation of this is that PPE such as gloves and protective breathing masks are provided for any activity where the PM could be potentially exposed to the atmosphere, adequate provision for containment of the PM is made once it is removed from a DPF, and that it is disposed of in a registered hazardous waste disposal unit.

DPF cleaning challenges

The method used for DPF cleaning faces its own challenges. It has long been established that using compressed air to blast out the PM is highly effective and efficient. It is a method endorsed by the

majority of vehicle manufacturers and OEM DPF manufacturers because it will not damage the substrate, unlike other methods such as chemical cleaning which can strip special coatings from the filter cells. Of course, given the harmful nature of the PM once in the atmosphere the air blasting method is potentially very hazardous for a workshop, and to approach the task without adequate safety methods would be very unwise.

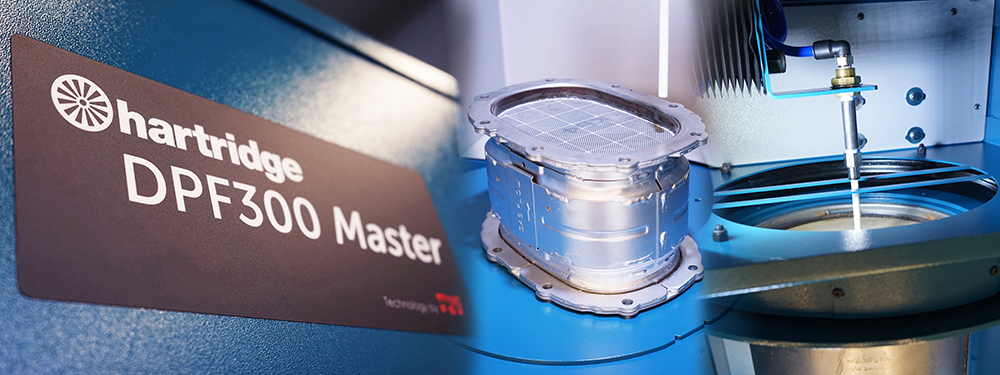

Although health and safety considerations are paramount, any DPF cleaning equipment needs to meet the workshop’s commercial and operational requirements to offer fast and effective service. An ideal DPF cleaning system would be as automated as possible in order to reduce human exposure to PM as well as help the workshop and technicians run as efficiently as possible and offer that fast service.

Hartridge says it is accustomed to engineering solutions with performance and safety in equal measure. It claims its authority on the subject is proven through 80 years of producing diesel fuel system testing solutions for OEM injector manufacturers. The DPF 300 Master series is said to be a solution that provides safety for a workshop, automation for productivity, and full flexibility to do a clean or a full thermal cycle depending on the state of the DPF. After all, the company believes that neither safety nor performance should be compromised.

www.hartridge.com