febi takes CVW readers through the essentials behind shock absorbers.

Since springs have the capacity to oscillate when the vehicle is travelling over uneven ground, the vehicle can start moving excessively. This can lead to a loss of road contact with the tyres. To prevent spring oscillation, shock absorbers are required to dampen the oscillation to a minimum and to keep the tyres in contact with the road for a comfortable and safe ride.

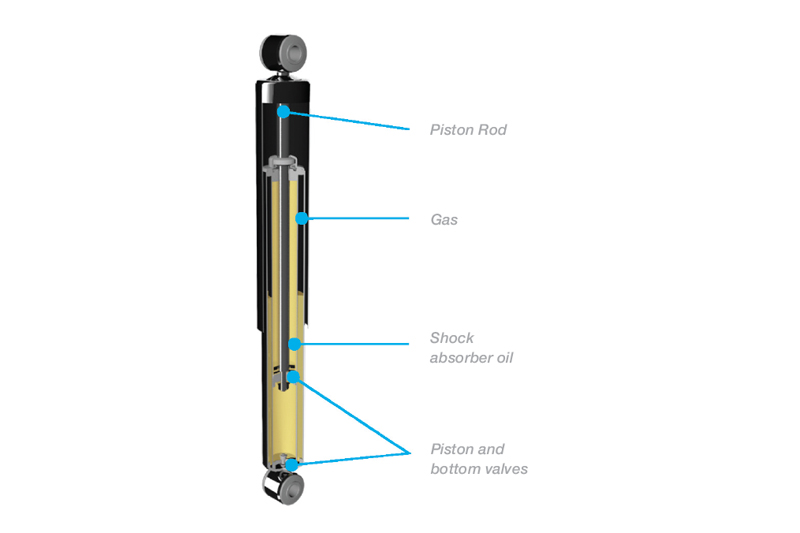

Gas and oil

Conventional shock absorbers are mainly produced as hydraulic telescopic shock absorbers in a single or twin-tube design. In the heavy commercial vehicle sector, mainly twin-tube gas pressure shock absorbers are used. The shock absorbers are filled with special shock absorber oil and a small amount of gas, which is usually nitrogen. The gas is needed because of its property to be compressible. When the piston rod is pushed into the shock absorber, it displaces the oil into the outer tube. The increase of volume of the push rod inside the shock absorber is compensated by the compressible gas, which decreases its volume.

Dampening characteristics

As vehicles are constructed in various configurations and have different weights, every shock absorber must have specific dampening characteristics according to the vehicle it is applicable for, according to febi. Chassis shock absorbers work hydraulically and the moving of the chassis is compensated by transferring the moving energy into friction energy. The friction is created by pressing the oil through the piston valves and bottom valves while the piston is moving.

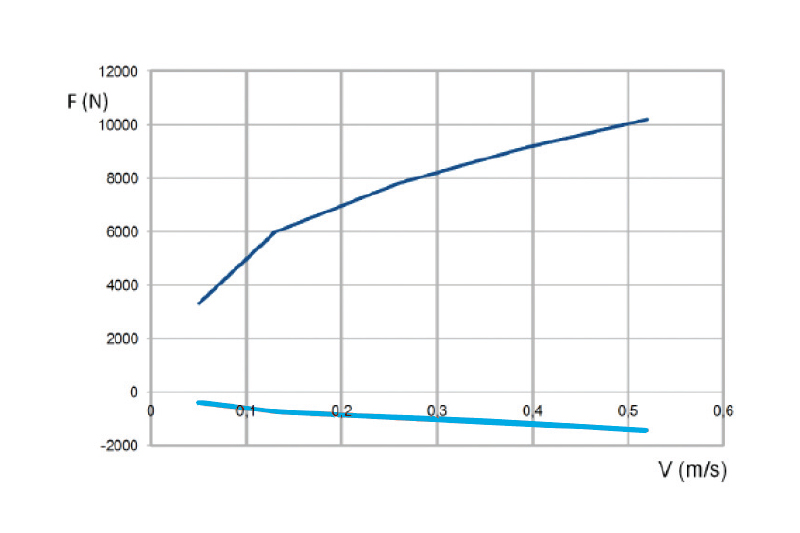

The different dampening characteristics can be achieved by the construction of the piston and the bottom valves where the oil is being pressed through. Their principle is based on the fact that the resistance to the flow of the displaced shock absorber oil depends on the flow velocity. It is not linear, but rather progressive, i.e., it increases with the flow velocity.

The push and pull forces are measured in comparison to the speed the piston rod moves in and out of the shock absorber. Only shock absorbers with suitable dampening characteristics can bring optimal dampening performance required for road safety and comfort.

Wear and its consequences

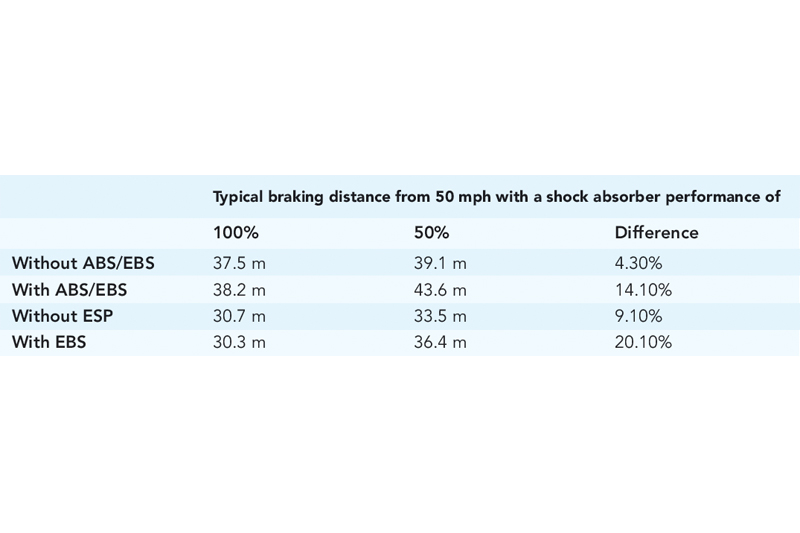

Shock absorbers are subject to wear. Various aspects influence service life and wear and tear, such as mileage, road condition, and the weight of the vehicle. Over time, the dampening performance decreases. This is a slow process, which the driver often does not recognise. For example, a loss of 50% of the dampening performance can result in a 20% extended braking distance when the optimal road contact cannot be achieved. The driver assistance systems are also very dependent on shock absorbers and a perfect chassis suspension.

Brake distance comparison

Besides the longer braking distance, febi explains that a vehicle with a poor shock absorber performance may break away in road bends and crosswind sensitivity may increase. This is particularly dangerous for heavy trucks because of their high centre of gravity and large wind-exposed area. In addition, the truck may dive under braking, making the vehicle unstable. Tyres wear out faster and driving comfort decreases.

Are the shock absorbers still okay?

Truck drivers should ask themselves this question regularly. But not every driver can answer this question sufficiently. The fact that the shock absorbers are worn out or defective can be noticed, above all, by significantly poorer driving comfort and in changed steering behaviour. If the tyre tread is not worn evenly, but varies in depth or is uneven over the tyre circumference, this also indicates defective shock absorbers. When the piston rod seal is leaking and the shock absorber is losing a significant amount of oil, which is easily visible on the outside, it should be replaced as soon as possible.

If there is any doubt about the condition of the shock absorbers, a professional workshop should be visited immediately. Trained specialists can detect defective shock absorbers and replace them professionally. In heavy commercial vehicles or buses, safety should always be the focus to not endanger other road users and to avoid dangerous driving situations and accidents.