With an extensive range of replacement parts for clutches and steering applications, febi takes CVW through its aftermarket offering.

More than 10,000 spare parts and 21,500 applications in OEmatching quality are available from febi, ensuring optimum availability of commercial vehicle replacement parts. Every second a commercial vehicle is off the road is money wasted, so it is important to use the highest quality replacement parts and check for any signs of wear or failure.

Steering

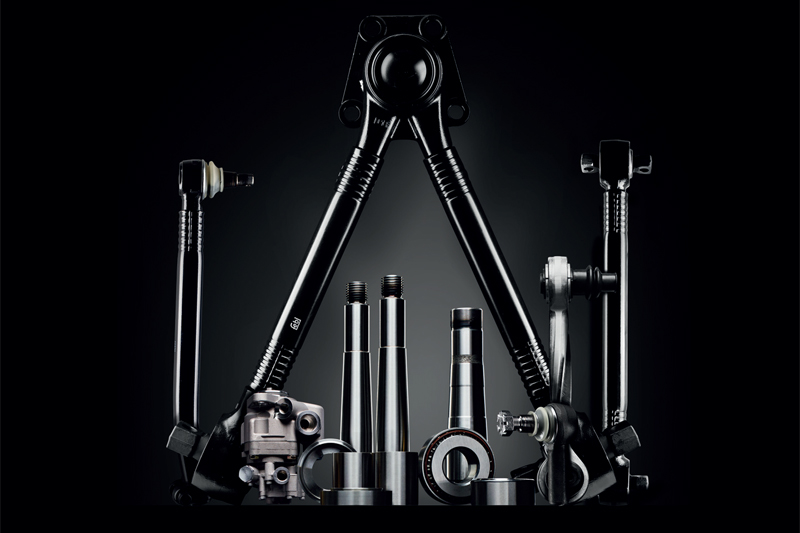

The steering range from febi offers top quality steel and OE grade rubber on all bushes, for a variety of vehicle makes and models. Driving vehicles with worn steering parts can not only lead to expensive bills, but also put lives at risk. This range of OE-matching quality steering components from febi ensures optimum performance and long service life.

Part of the range are OE-matching quality ball joints, which fit track rods, draglinks, throttle linkages, and steering rams. These safety-critical parts keep all vehicles, including heavy goods vehicles, safe and on the road by allowing controlled movement and offering enhanced driver comfort by absorbing vibrations.

febi Truck also offers a range of king pins, which ensure optimum performance by holding the alignment between the wheels and the axle to ensure steering feels lighter. The full steering range from febi Truck includes:

- Almost 400 drag links

- Over 100 tie/track rods

- Over 100 tie rod ends

- Almost 50 different stabiliser links

- Over 100 king pins

Clutches

A commercial vehicle clutch must ensure rapid and reliable disengagement and engagement of the torque flow between engine and gearbox. It must provide a high level of driving comfort by damping vibrations. febi Trucks’ range of clutch components includes:

- Clutch master cylinders

- Release forks

- Slave cylinders

- Concentric slave cylinders

- Clutch boosters

- Clutch kit

- Release bearings

Furthermore, advantages of febi Truck clutches include:

- Use of OE-matching materials – only the best resources are used in manufacturing processes

- Precision fit – febi ensures a precision match to OE clutches to maximise safety and comfort for the driver

- Designed for a balance of performance, driving comfort, and longevity

Before a new part is added to the febi range, the company carries out a first-sample test at its Clutch Competence Centre. Only high-quality components are used for manufacturing.

Quality is of the utmost importance to febi, as seen in the company’s protective, robust packaging and transport system. In addition to high performance grease for the lubrication of the input-shaft interface, febi also includes technical and fitting instructions with each kit.

The Clutch Competence Centre was introduced in 2017 and is situated in Durmersheim, Germany. At this centre, febi consistently optimises processes and strives to expand its range. With the aid of automated measurement tools, all product dimensions are checked to be accurate to the thousandth in order to guarantee a perfect fit. febi also uses specialist test beds to ensure the correct durability, functionality, and driving comfort is achieved.