febi’s deep dive into king pins

There’s a lot riding on king pins, so make sure you buy and fit the best and maintain them in the correct manner, says febi.

The steering behaviour of a vehicle can be adversely affected by numerous components of the chassis, including worn-out king pins and their bearings.

King pin wear tends to make itself known in the form of stiff steering, noise during the turning of the steering wheel, or uneven tyre wear. Further signs typical of king pin faults are problems with directional stability and the need for frequent, corrective steering action.

King pins play a supporting role. All steerable wheels of a commercial vehicle generally rotate about a king pin. The king pin attaches the stub axle to the wheel suspension and is, therefore, the only connection between the road and the axle. It forms the link between the sprung and unsprung masses of the vehicle.

The permanent exposure of individual components, including bearings, sleeves, and the king pin, to dirt and spray, leads to corrosion and wear. This process is further accelerated by the consequences of poor maintenance (e.g. lubrication), bad road surfaces, or vehicle overloading.

It’s therefore imperative to carry out regular inspections of these component parts. Before beginning, make sure to always review and follow the axle manufacturer and company maintenance and procedure manuals. King pin wear inspection requires that no weight be on the axle; so jacking up the front of the truck is required. Follow the correct procedures in your vehicle’s operating manual to properly lift the vehicle.

After the truck is lifted and no weight is on the axle, remove the wheels and tyres. Tighten the wheel bearing to eliminate any play that may be related to a loose wheel bearing. Another way is to have another technician apply the brake to differentiate between wheel bearing and kingpin bushing wear. Try moving the wheel left to right and top to bottom and up and down. If the wheel has any play you may have an issue likely caused by a worn king pin. Use a dial indicator to measure, axial and lateral movement which should not exceed 1/8in.

While there are external factors that impact the king pin’s functionality and lifespan, it’s always prudent to source good quality, durable, long-lasting king pins designed to withstand such conditions.

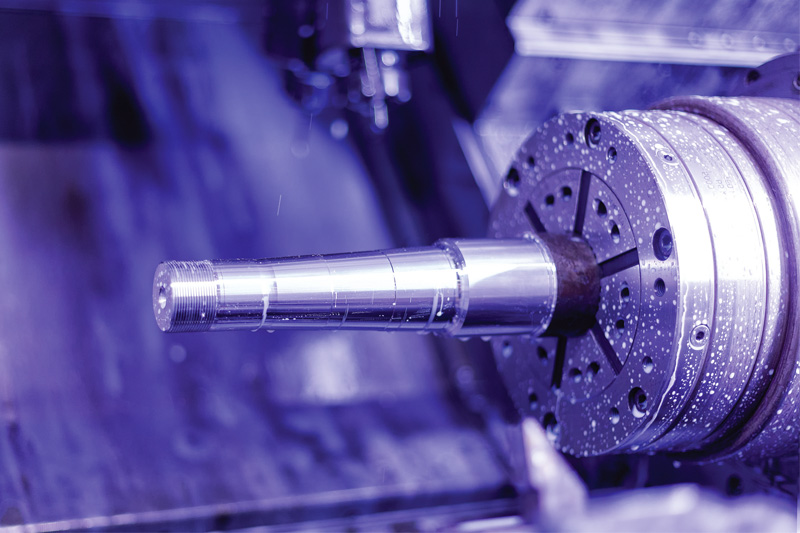

Febi’s range of king pins are manufactured on modern CNC machining equipment that guarantees the components’ quality, which are so vital to safety.

If replacement parts are not accurately manufactured, sharp edges may damage seals and allow water to penetrate into bearings. The correct inclination of the grease ducts for axle bushings is also essential to ensure the pivot points’ proper lubrication.

Precise machining and the pin’s surface hardness are the characteristic quality-features of king pin sets from febi. Our commercial vehicle engineers are well aware that a hard surface and perfect accuracy of fit ensure easier installation and smooth guidance of the pin. At the same time, it prevents shearing at the points of friction.

Precision matters

King pins, bushings, and bearings are safety-relevant wear parts. Dimensional deviations, insufficient hardness depths, and unsuitable material quality can lead to steering failure and compromise the brakes’ effectiveness, among other things. This can have severe consequences, so always choose king pins from a reputable supplier.

Complete repair kits

febi Truck has over 90 OE-matching quality king pin/sets covering all common European (“The Big 7”) manufacturers and models of truck, trailer and buses.

febi king pins also come available as complete kits via ProKit which contain all the required components necessary for a successful repair.

All parts are tested and manufactured to provide a long-lasting solution. With its ProKits for commercial vehicles, febi has established innovative, complete repair kit solutions for heavy-goods vehicles!