GEA discusses latest brake tester software

Julian E. Woods, chief executive, Garage Equipment Association (GEA), asks whether your HGV/ PSV roller brake tester is using the latest software.

The DVSA recently advised that all Authorised Testing Facilities (ATFs) will need to have their roller brake tester (RBT) software updated to meet DVSA testing requirements. To allow the equipment suppliers time to develop and deploy the updated software the DVSA has given industry a window of 18 months when either version of the software can be used. The deadline for all ATFs to be using the newest version of the testing software is now June 30th 2024.

Improve safety

Has your equipment supplier, maintainer, calibrator been in touch with you with reference to supplying the software update for your ATF RBT?

If not, we suggest you contact your supplier to find out when they will be updating your equipment to be compliant with the DVSA requirements including costs that may be involved to get the software installed to your specific RBT. You may be aware of the DTP database software updates being installed every six months on your RBT, but this is different, this time the whole RBT program needs to be updated.

The whole drive of this update is to help improve road safety and provide suitable and sufficient information to vehicle owners/ operators on the condition of their fleet by making the testing easier and giving the vehicle presenter/ owner more information on the condition of the brake of the vehicle being tested, as well as bringing the software up to date with testing requirements.

Feedback received from industry over recent years is that the HGV/ PSV brake test reports were not easy to understand and unless you knew the specific systems/ limits being applied etc, you may struggle to make an informed decision on the condition of the brake systems, with many people just looking for a pass or fail at the bottom of the sheet which may not give the whole picture on the condition of the systems on the vehicle.

This new software and printout now give much more information on the vehicle being tested, for example, during the test if a specific value or result is within a few percent of a limit then the RBT will display a live message to the tester on screen whilst the test is being conducted. This can help as information on the brake condition or it could be simply the driver has missed a command from the tester which could cause the test to be failed incorrectly. Now with these being highlighted in real time the error can be noted and that specific system could simply be retested at the time to see if it is really an issue or not.

Examples of screen messages

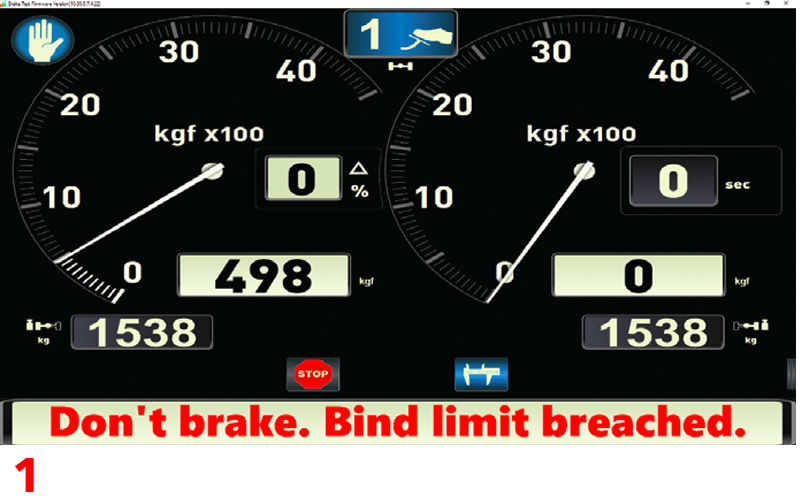

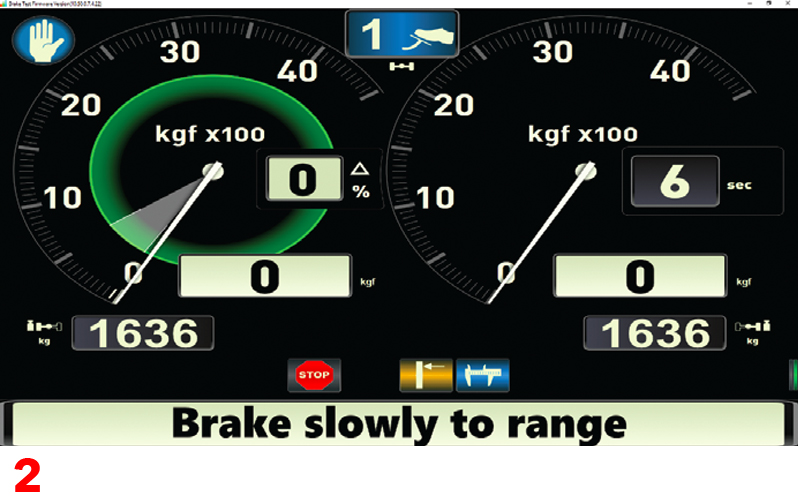

To the right are examples of screen messages. These might look different depending on equipment supplier but for our purposes show the following:

1: Showing bind limit breached.

2. Ovality test band to get the brake into the correct testing window.

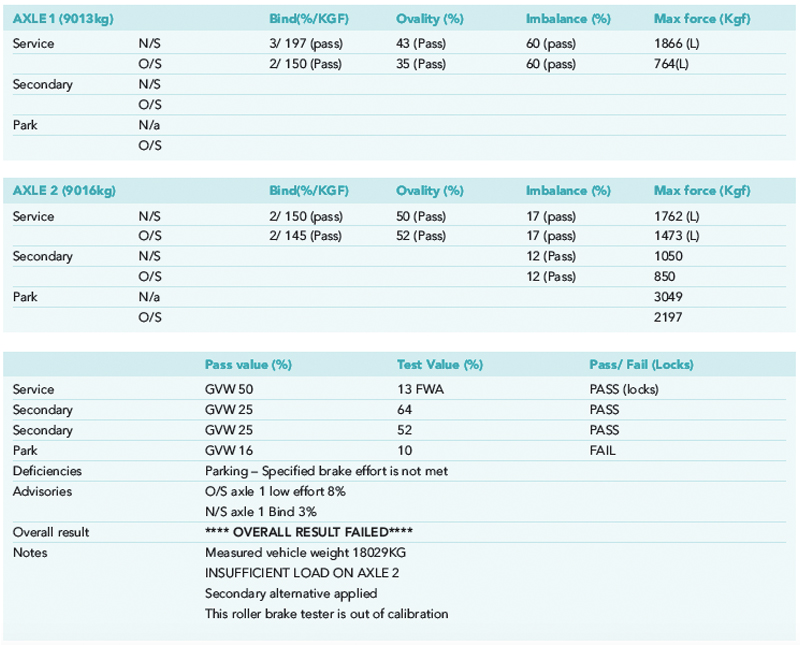

The same philosophy is used on the brake testing report, now giving clear information on any deficiencies identified on the vehicle/ system under test and now gives advisories when the brake result is near a limit. An example of (fictional) new test report follows:

Deficiencies: Parking brake effort not met. (as per previous software)

Advisory: highlights O/S axle 1 low effort, which may have been missed on previous report format unless you knew 13% service brake efficiency even with front wheel allowance (FWA) only passed as wheels locked. Bind has been advised as 3% on N/S axle 1 as bind fail tolerance is 4%. This result is a marginal pass.

The new software packages not only address screen prompts and reports but also address many other areas of the test such as applying a default split routine when no split is defined within the DTP number, keeping assessment/calculations consistent wherever your vehicle is tested, and the addition of drawbar trailer testing routines along with many more updates in line with the DVSA testing manual.

Six month calibration period

With the new software requirements, the DVSA has also improved RBT calibration and accuracy. RBTs and the RBT’s weighing system calibrations must now meet ISO 21069-1-2004 and be fully traceable to a national standard, including the engineer who performed the calibration being recognised by an independent trade body as a competent person for performing brake tester calibrations. The calibration period has not changed (still every six months) but now the RBT software will give visual indication on screen if the unit is out of calibration and record / print any tests completed when the RBT was out of calibration.

All DVSA approved ATF roller brake testers and all other DVSA specific approved testing equipment used within the MOT testing industry is identified by an equipment identification number (EIN). This is an alpha numeric number issued to the equipment manufacture / importer / distributor when the equipment has been validated as meeting the minimum requirements of the DVSA specifications.

Approval number

If your equipment is being updated by your supplier, they should issue you a new DVSA acceptance certificate with the new approval number (EIN ****) updating the physical label on your RBT console so should anybody needing to verify its status can do so against the master database of approved equipment.

Should you be looking to replace your existing RBT equipment or simply buying new equipment to be used in an ATF site, always check the status on the approved equipment listings before completing the purchase to ensure it meets all the current DVSA requirements.

Know your status

A database of all DVSA-approved MOT equipment can be found on the Garage Equipment Association’s website and will show you the current status of your testing equipment, classes of testing the equipment is approved for, and much more. For this specific update in the additional description column you need to see 2022 ATF software to show it’s been tested and approved against the DVSA’s 2022 ATF software specification, and not the earlier ATF software of 2011.

NB: the list will show the minimum software revision/ version number that is acceptable. We do recommend you check the full EIN number as some equipment model numbers may have different approval levels depending on the software installed on it. To view the list, click here.