Andy Currell, Training, Product & QC Manager at ISN talks you through the process of changing a truck tyre, using the Hofmann Megaplan megamount 352, one of the specialist commercial vehicle tyre changers available in its range.

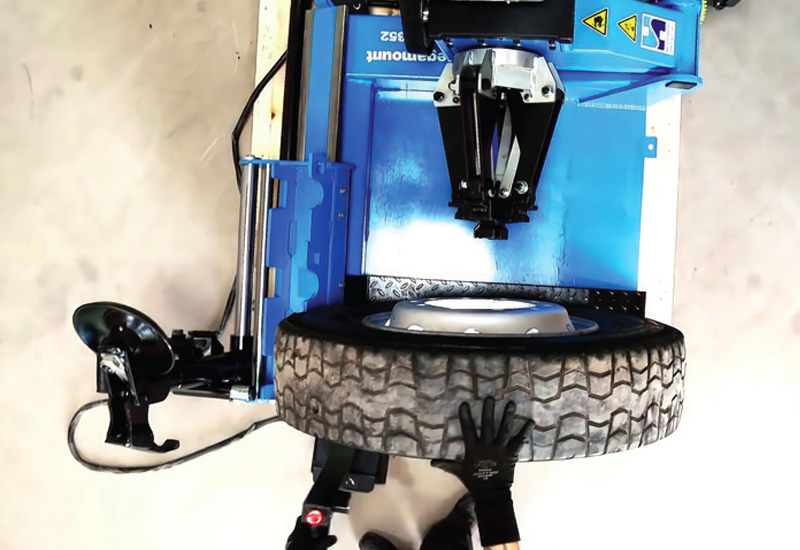

- Before attempting any tyre change, remove the valve core and release the air from the tyre. Roll the wheel onto the platform of the megamount 352; the type of rim will determine which side of the wheel should face the jaws (or chuck) of the tyre changer.

-

While steadying the wheel with one hand, use the controls on the portable control unit to move the platform toward the chuck.

-

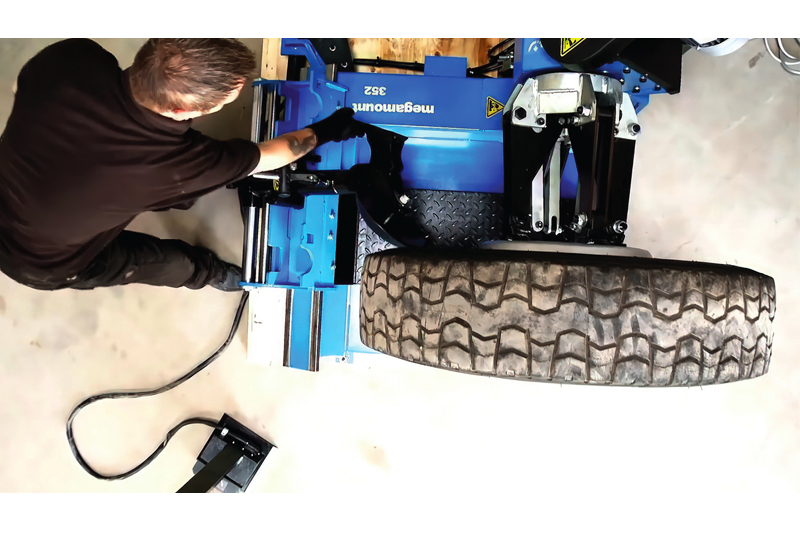

Once in position the jaws of the chuck can be opened to grip the centre of the wheel.

-

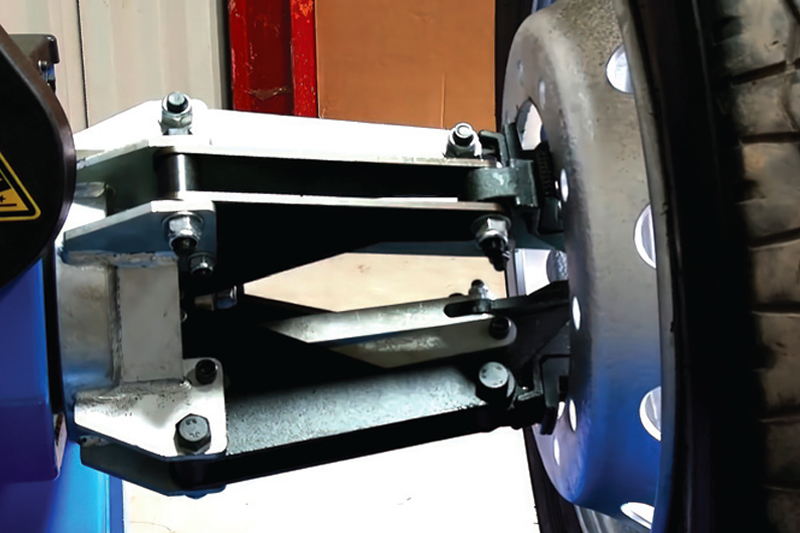

Using the controller, lift the wheel off the platform and reverse the platform out of the way. The platform carriage incorporates a multi-function ‘Double Tool’ – a bead breaker/tyre demount/remount disc and hook all-in-one, which is now manoeuvred and locked in position by hand, ready to break the bead of the tyre away from the inside of the rim. It’s most likely you’ll use the disc for this operation but, depending on wheel/tyre combination, the hook could also be used for this purpose. However, it’s mainly employed to remove one side of the bead if the tyre has a puncture. If a valve needs replacing, the disc can be used to push the bead out of the way to allow access to the valve without removing the tyre.

-

The easy to use controller allows you to lift the wheel to the optimum height and position the Double Tool, mounted on the carriage against the tyre. A combination of wheel rotation and Double Tool pressure on the bead gently forces the tyre off the rim, allowing you to apply tyre paste/soap to lubricate the bead.

-

The next step involves retracting the Double Tool, moving it to the other side of the wheel and rotating it through 180 degrees. The carriage will then press it against the other side of the tyre, to break bead on the other side of the wheel.

-

As the bead is broken, lubricate it with tyre paste; the carriage will continue to press the Double Tool against the tyre as the wheel rotates…

-

…eventually pushing it off the rim.

-

Mounting the new tyre is, arguably, an even simpler process and, once again, it uses the Double Tool to press the beads of the tyre over the wheel rim. Start by laying the bead of the tyre over the rim.

-

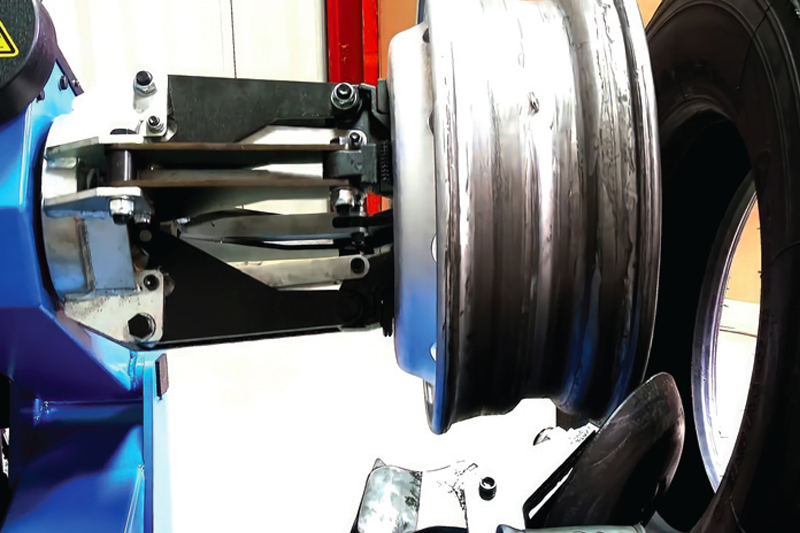

Position the Double Tool against the tyre and the machine can go to work, pressing the outer bead over the rim while the machine rotates the wheel.

-

A specially designed clamp stops the inner bead from rolling back off the rim as the mounting head pushes it over. A kit for alloy wheels is available, which includes a set of jaw inserts and a clamp, both designed specifically for alloy wheels.

-

And that’s it! Once the machine has done its work you can retract the Double Tool, lower the wheel back onto the platform and release the chuck.