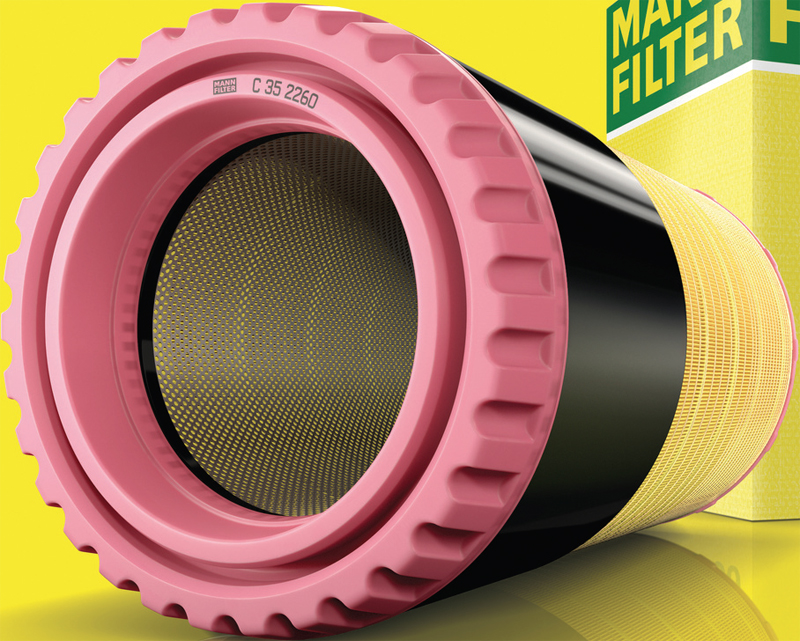

Developing a high-quality engine air filter is not simply a question of choosing the right filter medium; the seal must also be effective. Mann-Filter explains why the seal is key.

The connection between the filter element and housing must be elastic, compressible, and heat- and tear-resistant. The seals on air filter elements, which are generally made of polyurethane foam (PUR), must meet demanding requirements if they are to provide a tight seal between the filter element and air filter housing. They need to be extremely elastic, and also have a high heat resistance.

Choosing the correct seal outline is also a decisive factor in determining the quality of the seal between the filter element and the air filter housing. The outline of the seal on Mann-Filter products is, therefore, adapted to fit the individual housing. If the engine is likely to reach particularly high temperatures – for instance, in vehicles with low-pressure exhaust gas recirculation – Mann-Filter uses a silicon which is heat-resistant to 150°C, in order to comply with vehicle manufacturer requirements.

If inferior products do not comply with the manufacturer’s requirements in terms of its material properties or shape, this can have serious, negative consequences. If the seal is too hard, the filter element is difficult to install and the housing may be distorted as a result of the increased forces exerted on it. This can quickly cause the air filter seal to loosen and allow small dirt particles to enter around the side of the filter element.

These dirt particles will eventually damage downstream components, such as air flow meters, turbocharger compressor wheels, pistons, and cylinders.

The dirt particles act like a sand-blasting machine and can hugely distort the shape of components, such as turbocharger compressor wheels. Damage may also be caused to air flow meters. In this instance, the quantity of available air may be incorrectly measured. As a result, optimum combustion does not take place, thus reducing fuel economy. In the worst-case scenario, the engine control unit in modern vehicles will switch the engine to emergency mode (as required by European emission standards, Euro VI), if the engine is not combusting properly and, therefore, does not comply with the standards.

When changing air filter elements, Mann-Filter recommends always using products in OE quality to protect the vehicle against increased wear, prevent damage to the engine, and prevent any reduction in performance. It is also important to check the sales label in the Mann-Filter product catalogue prior to installation, to ensure that you have the right filter for the vehicle. This is in order to clear out the incoming air side of the housing using suction, and to make sure that the new filter element is correctly aligned. The correct position is generally indicated by a mark on the filter element or the housing.