There are many misconceptions that remain in the industry and one of those is that air conditioning service and maintenance is only relevant to the spring and summer seasons. Nissens explains why this isn’t the case.

Air conditioning (A/C) is not just a comfort system because it’s an important safety feature for drivers of commercial vehicles as good visibility is a necessity, whatever the time of year.

Although many only associate A/C as a means of remaining cool when the weather is hot, the fact that the A/C system also dries the air coming in to ventilate the cabin, significantly reducing its humidity, means that using the A/C is the quickest and most effective way of reducing condensation inside the vehicle and preventing the windows from misting up.

In addition, using the A/C regularly keeps the oil/refrigerant mixture moving around the system, which ensures its internal components, particularly the compressor, remain sufficiently lubricated. So, using it all year round really is the best, and safest, option.

As a result, A/C system repair and maintenance should be equally important to the CV workshop in the autumn and winter as it is in the spring and summer, and A/C system specialist Nissens Automotive is on hand to provide them with the technical advice and replacement components they need for them to do so.

What to look out for

Irrespective of the primary reason why a vehicle visits the workshop, technicians should always carry out a visual inspection of the A/C system looking out for leaks, oil residue on component surfaces, around joints and couplings.

Focus on the condenser

A faulty condenser, even if it is still partially working, can lead to severe A/C problems and sometimes result in damage to, or even seizure of, the compressor, which is a very costly component and its replacement will take the vehicle off the road as the rest of the A/C system will need to be examined, flushed and the oil/gas refrigerant mixture changed.

Background

The condenser is typically attached to other heat exchangers in the engine compartment and is crucial for the A/C system’s operation as it ensures that the refrigerant changes from a gas to a liquid state. This is achieved through the condensation process, where the refrigerant heat is extracted, which cools the condenser. The airflow then passes the colder air through to the cabin.

The problem

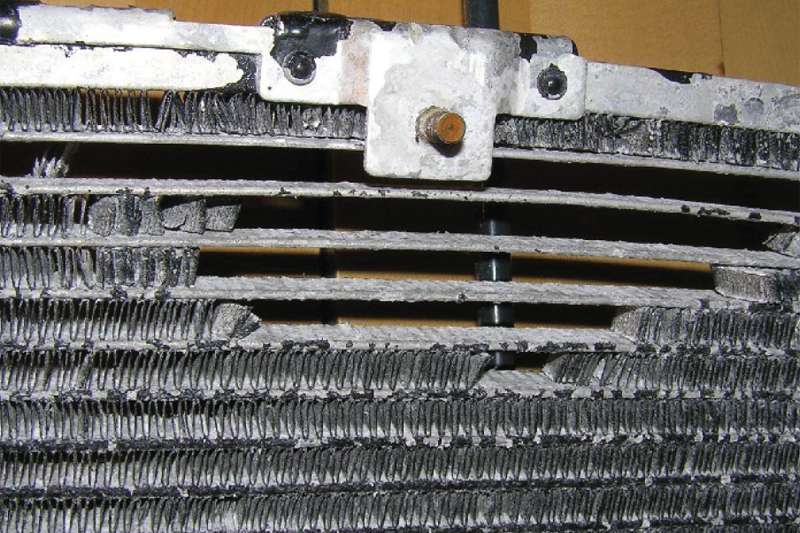

Mechanical damage to the condenser is often disregarded as a reason for reduced system performance or for compressor failure, because leakages and surface perforations are generally considered as the most common reasons for system failure. However, even light mechanical deformation of the condenser tubes and fins can result in serious system performance limitations. Only one deformed condenser tube is needed to restrict refrigerant flow inside the unit, which can reduce the system’s performance significantly.

Furthermore, limited flow will cause abnormally high pressures and temperatures in the loop. These will increase the compressor workload and effectively reduce its lifespan or, in the worst case, cause it to break down.

The Nissens solution

Always handle the condenser with proper care and do not disregard any light damage on its surface. If the tubes and/or fins are visibly damaged, replace the condenser with a new unit.

In addition, regular visual inspection of the condenser surface can save expensive system and compressor repairs and costly vehicle downtime. So, any signs of corrosion or leaks on the condenser surface must be considered as serious threats to the efficiency and operation of the system. Pay particular attention to the bottom part of the condenser, where tubes and fins are mostly exposed to humidity and aggressive salt spray. If there is any sign of leakage, or missing/deteriorated fins are seen, the condenser must be replaced.