Aaron Cafano, technical manager for Totalkare, looks at the importance of supporting vans on two-post lifts during heavy element removal.

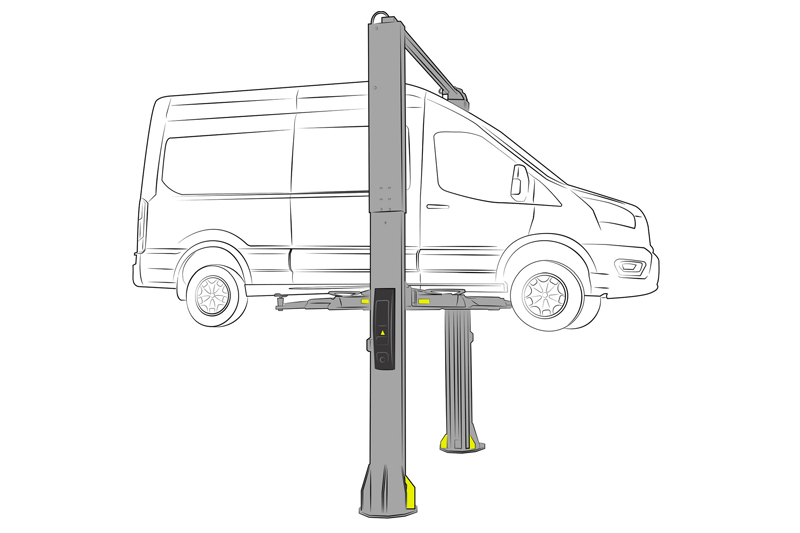

In the world of repair and maintenance, precision and safety go hand in hand. When it comes to lifting vehicles on two-post lifts for servicing tasks like removing heavy elements such as the engine or gearbox, one must be acutely aware of the potential risks and necessary precautions. Of critical importance is supporting vans on two-post lifts when removing elements that could alter the vehicle’s centre of gravity and unbalance it on the lift.

In the balance

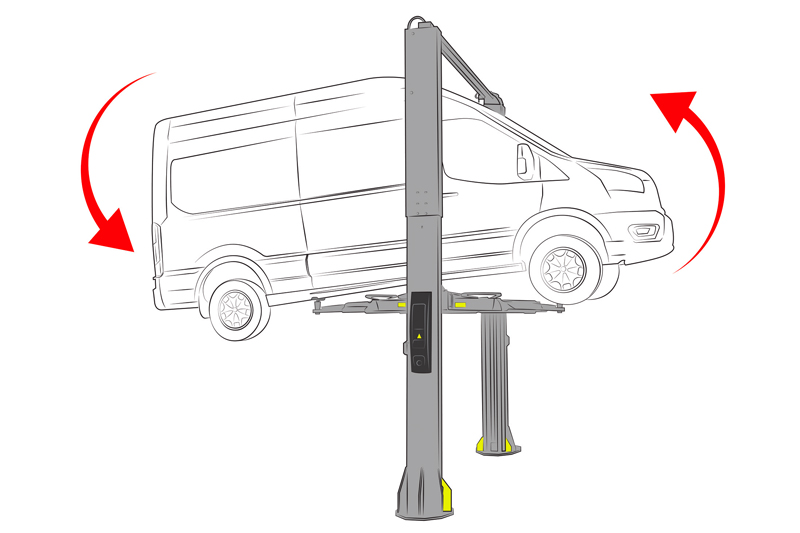

Vehicles, especially vans, are engineered with specific weight distributions and centre of gravity to ensure safe handling and stability during operation. However, when you raise a vehicle on a two-post lift and then remove a substantial component like the engine, you dramatically alter its centre of gravity. In some cases, this can shift as much as 800kg, a significant difference when considering that the total weight of the vehicle may be around 2,000kg. This shift in weight distribution necessitates a re-evaluation of the positioning of the lifting points.

Check load distribution

One critical factor to consider is the content in the rear of the vehicle. The positioning of the lifting arms may need to be adjusted depending on whether the rear is fully loaded or empty. Failing to account for this can result in an uneven load distribution that compromises stability and safety. If it’s not possible to empty the rear of the vehicle, supplementary axle stands should be used to provide additional stability and prevent the vehicle from tipping.

Using the correct lift adapters is also paramount to ensuring the safety and stability of the lift. Specialised adapters, such as Totalkare’s two-post lift Crafter/ Sprinter kit, are designed to suit specific vehicle types and maintain secure lifting points during component removal.

Equal extension of lifting arms

Maintaining equal extension of the lifting arms on either side is another crucial aspect of using a two-post lift for heavy element removal. This practice ensures an even spread of weight distribution, minimising the risk of unbalancing the vehicle on the lift.

By adhering to these good practices, you not only enhance safety standards in your workshop but also help prolong the life of the lifting equipment itself. Regular maintenance and inspection of the equipment to ensure that all safety devices are in working order are essential.

This not only keeps the equipment in optimal condition but also reduces potential downtime, contributing to efficient and safe working practices.

Another important consideration when using two-post lifts is the vehicle’s height. Care must be taken to avoid interference with the gantry at the top of the lift. Contact with the gantry has the potential to compromise the balancing cables on either side, which can subsequently unbalance the lift and the vehicle being lifted on it.

Failing to adhere to these safety precautions can lead to dire consequences. An unbalanced vehicle on a two-post lift can tip or fall off, resulting in damage to the vehicle, workshop floor, surrounding equipment, and potentially compromising the installation of the lift itself.

In conclusion, when it comes to removing heavy elements from vans using two-post lifts, meticulous attention to detail and safety is paramount. Properly supporting the vehicle, considering its weight distribution, using specialised adapters, and maintaining the lifting equipment are all essential steps in ensuring the safety of both the vehicle and the technicians working on it. By following these practices, you can prevent accidents, protect your equipment, and maintain the highest safety standards in your workshop.