UFI Filters discusses Argentium filters

With the introduction of its UFI Argentium filter range for trucks and buses, UFI Filters has made the next level of cabin air filtration available to the commercial vehicle sector. Karl Ridings, sales director and general manager UK & Ireland – Aftermarket at UFI Filters, explains how Argentium helps to make the air inhaled by professional drivers and bus passengers even purer, while also improving driving comfort.

Everyone agrees that a properly functioning cabin air filter is of utmost importance to everyone inside a vehicle. Although the concentration of dust in the atmosphere and the presence of various harmful particles such as PM10 and PM2.5 varies with weather conditions and geographic location, levels inside the vehicle can be as high as six times the outdoor level. This surprising fact is due to the tunnel effect created by the ventilation circuit. The direct effects of any poor air quality on both drivers and passengers can include allergies, sore throat, sneezing, reduced alertness and even poor visibility due to condensation on the windscreen and windows.

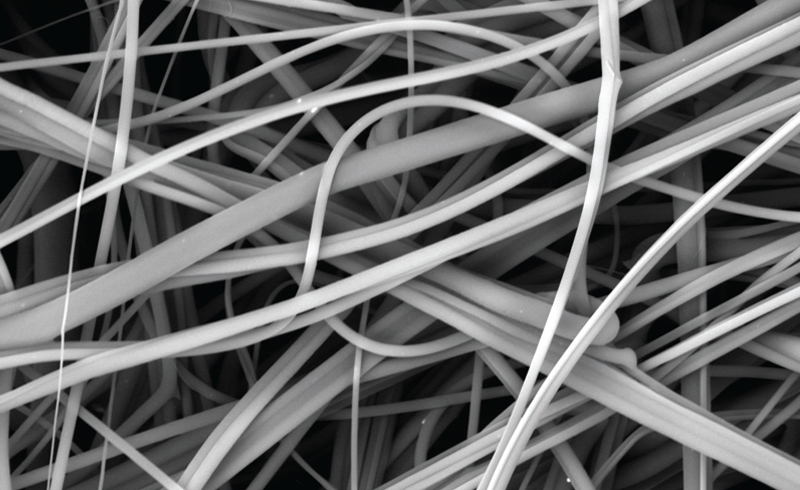

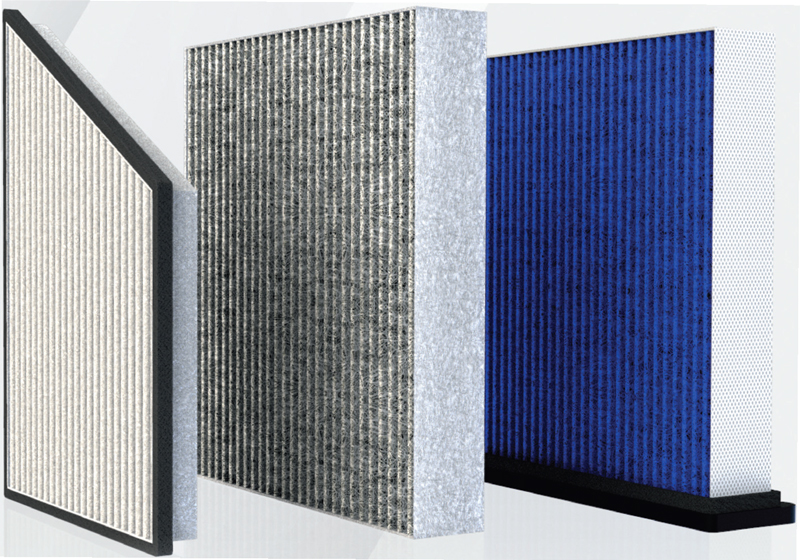

In the past, there were mainly two kinds of cabin air filters – anti-pollen filters with a synthetic non-woven fabric, and filters made of a filtering non-woven fabric combined with active carbon. The former can hold back over 90% of particles with a diameter greater than 2.5 μm, such as dirt and pollen. The latter on the other hand, can prevent particles of between 0.01 and 2 μm, such as gases, bacteria, fungi and odours from penetrating the cabin. Both solutions can be installed to the vehicle owner’s preferences, location and sensitivities, although this may depend on the particular vehicle model in question.

Products in the market

Filter tips

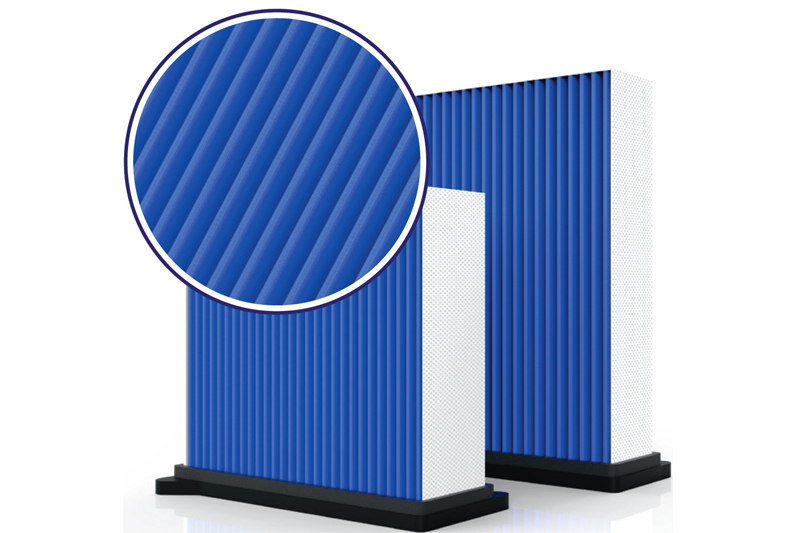

Recently, some cabin air filter manufacturers have extended these traditional options with new product groups that are designed to block and destroy bacteria even more efficiently. These types, however, tend to deteriorate within only a few working cycles after installation. To find an optimum solution, UFI Filters has used its renowned commitment to innovation to develop a different concept called Argentium, which can maintain its full filtering properties throughout the filter’s entire lifetime. The new technology has now been introduced to complement the company’s pollen and activate carbon cabin air filter ranges in the aftermarket. Argentium features distinctive, bluecoloured fibres and a special fabric structure which incorporates silver particles that deliver powerful antimicrobial characteristics. Furthermore, tests carried out at the UFI innovation centre have shown that this innovative product maintains its ability to inhibit bacterial growth, fungi and mould up to 99%, thanks to the incorporation of Biomaster silver biocide, tested to ISO 22196:2011.

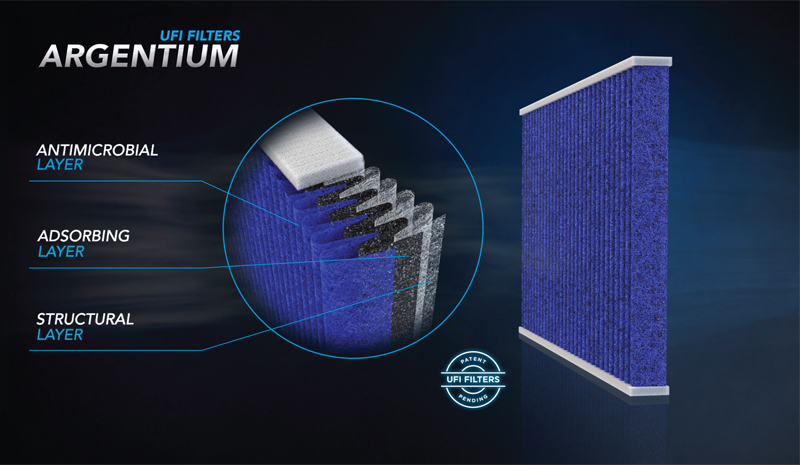

In terms of design, UFI Filters’ new Argentium filtering media is composed of three layers: antimicrobial, adsorbent and structural. Combined, these layers stop pollen, dirt, tyre-wear dust, fungi, mould and inhibit bacterial growth, while absorbing sulphur dioxide (SO2) and nitrogen oxide (NOx). Thanks to the presence of active carbon, the material guarantees a filtration efficiency that exceeds 98.5% for particles with a diameter of 2.5 microns, as well as eliminating harmful gases and unpleasant odours. The filter is fully compliant with the ISO 11155-1 standard.

Aftermarket offer

The UFI Filters aftermarket catalogue currently incorporates 111 cabin air filter references for trucks and buses, now encompassing all three key filtration technologies. This range has grown significantly in recent years, ensuring that more than 98.5% of the vehicle parc on Europe’s roads are covered by UFI Filters.

Options include 84 pollen filters made with synthetic non-woven filter media, capable of retaining over 90% of particles with a diameter greater than 2.5 μm, such as PM10 fine dust, dirt and pollen. UFI pollen filters can be identified in the catalogue by the initial code 53. The company also offers 14 carbon filter references consisting of non-woven filter material combined with activated carbon – which, in addition to removing fine particles, absorb gases and odours, and block industrial and agricultural pollutants such as hazardous NOX, SO2, NH3 and VOC. UFI carbon filters ensure greater protection inside the vehicle and can be identified in the catalogue by the initial code 54.

CV professionals seeking even more filtration benefits can also now select from 13, advanced UFI Argentium filters. Each reference offers the technology’s unique antibacterial properties, including the revolutionary, three-layered filter media featuring Biomaster biocide silver that can reduce bacterial growth by up to 99%. These Argentium UFI filters carry the initial code 34 in the catalogue.

Apart from blocking allergens and fine dust and removing bad smells, cabin filters are becoming increasingly essential to protect drivers and passengers from microorganisms. We are seeing particular demand for Argentium filters for both long-distance and city-based buses, which carry a lot of passengers. That’s exactly why UFI has concentrated on the heavy vehicle segment. Our first references were launched back in 2022, initially for buses and later for heavy duty vehicles, and now the range covers around 1,000 applications across Europe.

For buses, these applications include the MAN Lyons Intercity and NG series, the Mercedes-Benz Citaro, the Scania OmniExpress, the Iveco Crossway and Urbanway model-series and the Viseon Bus. The expansion to include heavy duty vehicles already offers coverage for a comprehensive range of models from MAN, Iveco, Renault Trucks, Scania, Volvo, DAF and Astra.

Although the standard rule of thumb for replacing a cabin air filter is once a year, in fact it should be done at even shorter intervals for high mileage vehicles or especially dusty areas – both of which accelerate the rate of wear.

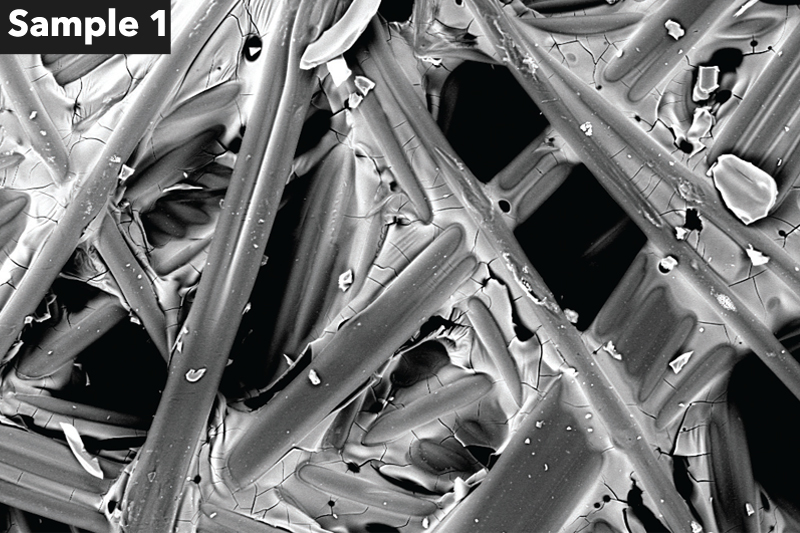

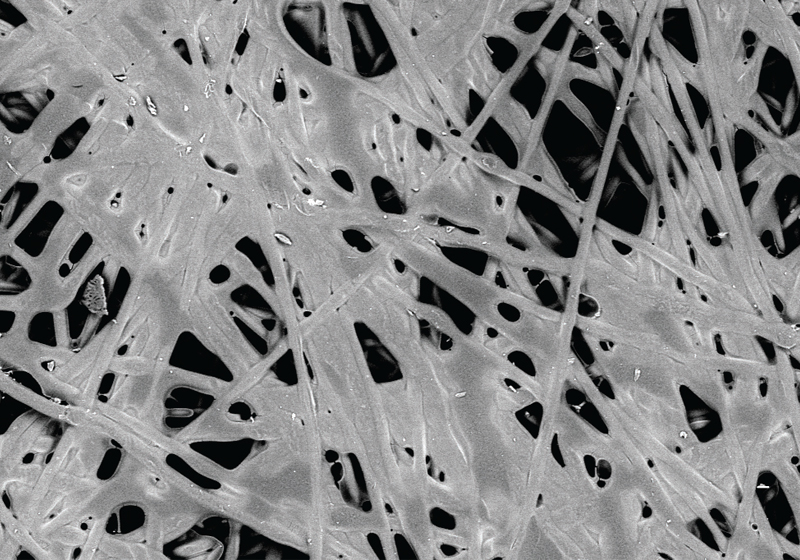

Pre-ageing coated filter media

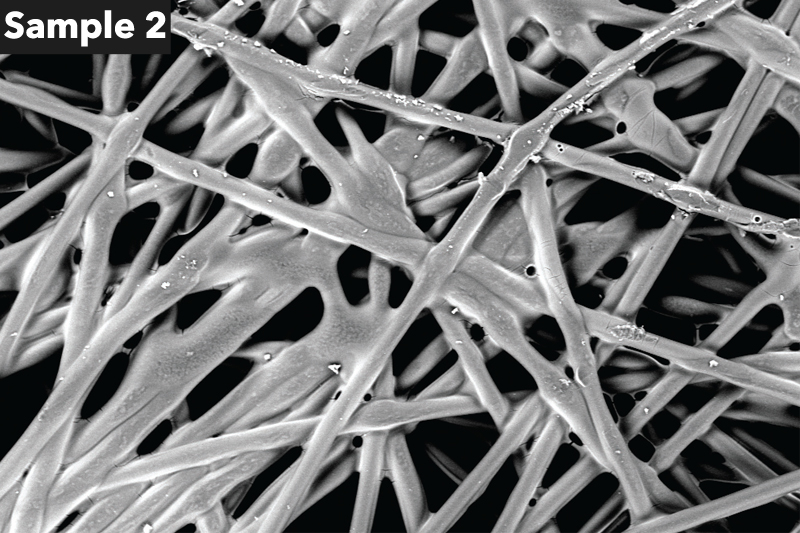

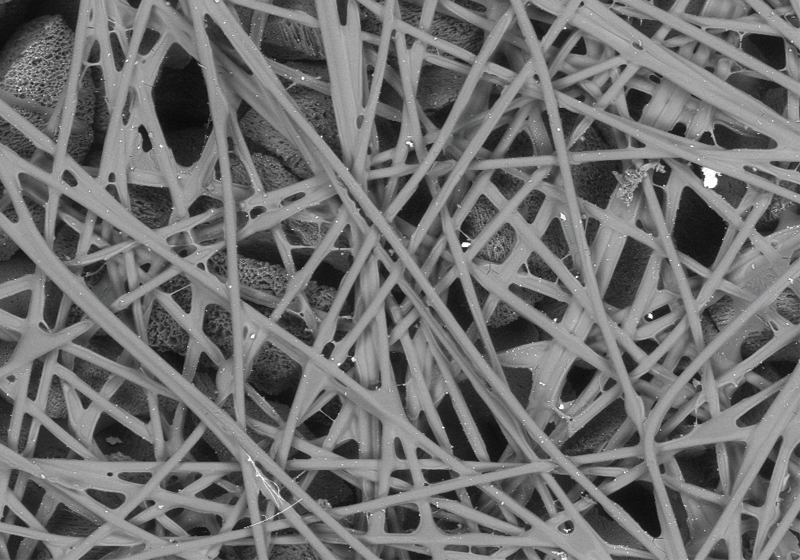

After-ageing coated filter media

One of the most common reasons for filter malfunction is also one of the simplest to solve. Always select the recommended cabin filter part number for the specific application and follow the vehicle maker and filter manufacturer’s service procedures. Getting these wrong is the surest route to filter malfunction or even collapse!

![Bosch outlines ESI[tronic] workshop software](https://cvwmagazine.co.uk/wp-content/uploads/2025/07/Bosch-ESItronic-25-165x109.jpg)