Together with its Jaltest software, Eclipse Automotive Technology’s Testpad Extreme PC, which is customised to fit the workshop environment, has proven popular with workshops of all sizes.

The on-going development of the Testpad Extreme PC and Jaltest diagnostics software has given additional strength to the buying decisions of workshops, asserts Eclipse Automotive.

New Jaltest versions are available every four months to include new brands, new models and improved diagnostic data on current offerings. June marked the launch of Jaltest 18.2, the latest version and the second update of the Jaltest multi-brand software this year. It continues the expansion and depth of vehicle coverage, adding new functionality and enhancementsto some of the features that already exist.

Here, the company covers what’s new.

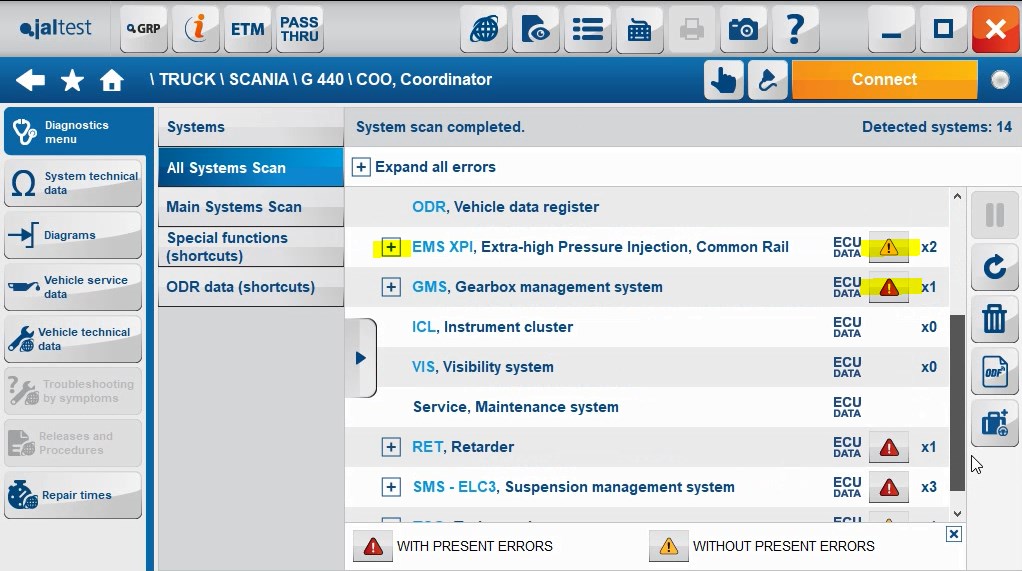

System scan function

To help the user more accurately recognise errors on the vehicle, the software can now show both the error and error-free scenarios. This feature aids the user in detecting which control units have active errors and will require further investigation. By clicking on the Error icon, it will connect to the selected ECU. Below we can see how this is displayed in the Jaltest software.

Relationship between component test data and live readings

It can be very useful to compare the static test of a component to that produced in the live environment. It can lead to a much more accurate diagnosis and perhaps avoid unnecessary component replacement. This gives the ability to switch from component testing information and live measurement data. The addition allows the user to view the required figures for voltage and resistance, and also see what the actual value is reading in real time.

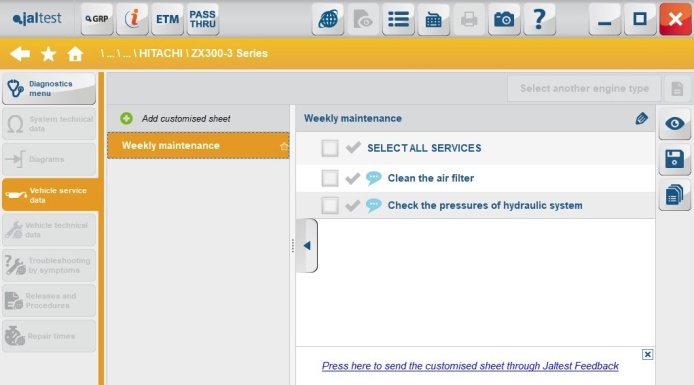

Customer maintenance service schedules

Jaltest already incorporates service schedules and maintenance plans. However, the user now has the ability to amend these to the requirement of their fleet. This can be the addition of a part that requires a weekly check, or a particular service plan the vehicle needs for a specific operation.

New models, systems and functions

Jaltest has been significantly enhanced in version 18.2, with all areas of the software receiving new models, systems and functions. To list a few, Volvo/Renault has seen the introduction of the AdBlue ACM module V3 & V4, Scania the Coordinator COO8 and APS2 systems, the MAN range to include the TraXon Gearbox and Mercedes has had the CPC Common Powertrain Controller variants enhanced.

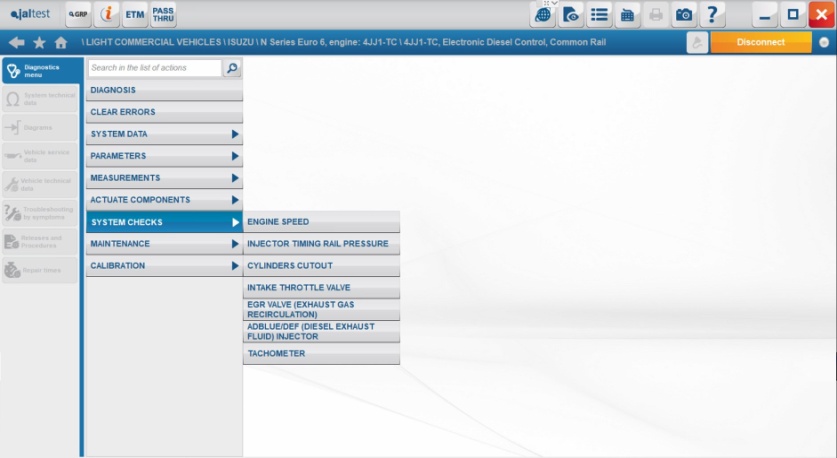

New model – Isuzu N & F Series Euro 6

In version 18.2, Jaltest has developed the software for the new Euro 6 N & F Series, giving the user the ability to diagnose and perform an extensive array of calibrations, system checking and maintenance tasks, such as:

■ Particulate Filter Regeneration

■ Injector Coding

■ Oil Dilution Reset

■ Particulate Filter Differential Pressure Sensor Calibration

■ Reset of many component adaptation values (NOx Sensor, Throttle Valve, SCR CAT, etc.)

New function – DAF/IVECO Euro 6 AEBS WABCO

The AEBS (Advanced Emergency Braking System) fitted to DAF & IVECO Euro 6 vehicles has a counter which monitors the amount of emergency braking events that the system has detected. This can be caused by a number of influences:

■ Road characteristics and traffic situations

■ Driving style

■ Damage to vehicle or incorrect mounting of components

When the system detects three or more emergency braking events, it requires resetting or the system becomes deactivated. Jaltest now has the ability to reset the AEBS system to ensure it remains active and fault free.

Also integrated into the AEBS system is the detection radar which is located on the windscreen. If this becomes defective, falls off, or if the windscreen requires replacement, then the radar will require calibration. Jaltest now has the function to carry out this operation.

New system display – VOLVO V4 Euro 6

This is a new software enhancement for the V4 Multimedia and Telematics System. With the extensive amount of multifunction controls the driver now has at their fingertips, Jaltest has developed a great way in ensuring they are all operational in one, easy-to-view system display format. This can quickly and easily identify faults without having to process each one individually.