In the first of a series on disc brake servicing, MEI Brakes has some practical tips on preventing water damage to brake calipers.

Maintenance of air disc brakes has been a part of regular workshop practice for more than 20 years, and most workshops will feel confident with all service aspects.

Even with well established ADB servicing practices, water ingress to the caliper remains an issue for many end-users and most of these cases are due to water ingress through the air chamber.

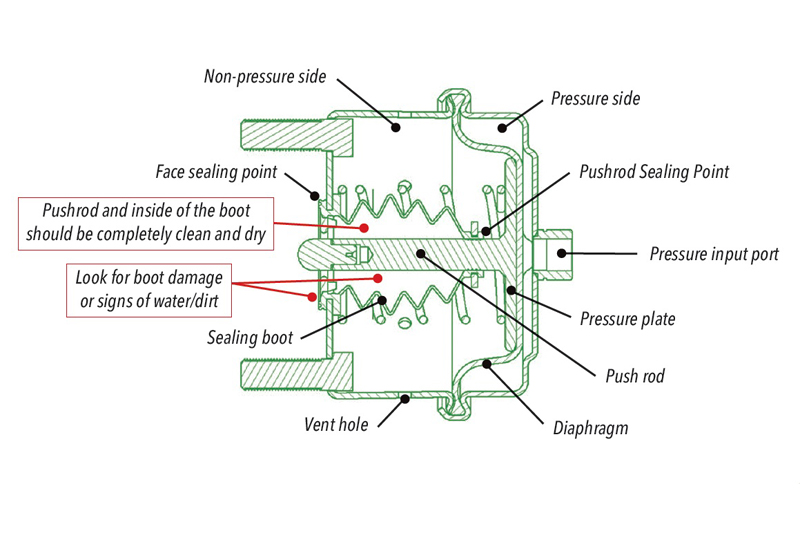

Air chambers have a pressure side and non-pressure side. The non-pressure side (closest to the caliper) has to be vented to atmosphere, and hence water can be present here also. On a drum brake this is not an issue as the pushrod is detached from the internals of the brake. However, for an Air Disc Brake, the pushrod has to be fully sealed against the non-pressure side of the air chamber so that water is kept out of the brake. If this seal is damaged, or ineffective, the brake will quickly become permanently damaged (through corrosion).

Note the face sealing point and pushrod sealing point in the layout of air chamber parts (Fig 1).

So, what happens if the air chamber seal is damaged or ineffective? The following photographs show the resulting corrosion after brakes have been fitted with an air chamber with a damaged seal:

This brake had a reported fault after less than two weeks service – water entered through the air chamber seal, which created an electrical fault, highlighting the issue as a ‘worn-out pad’ signal in the cab (Fig 2).

More normal is for water to enter the brake and be undiscovered for weeks or months, until brake efficiency reduces, which is then picked up on rolling road inspection or test. This brake is completely beyond repair and had been fitted with an air chamber with a damaged seal (Fig 3).

Preventing Water Ingress

So, when fitting an aftermarket caliper to a truck, how does the mechanic determine if the air chamber is still serviceable? Checking that the pushrod operates correctly with no air leaks at the diaphragm is only one part of the process, the mechanic must also ensure that the caliper is not subject to water ingress through the air chamber by checking the push rod boot/seal:

1. First check the flange seal that is visible on the air chamber mounting face. The protruding seal should be at least 3mm proud of the non-pressure chamber (air hamber body), and without any damage or nicks (Fig 4).

2. After checking the flange seal, carefully inspect the visible part of the pushrod. If water or rust staining is present on the pushrod, it is a clear sign that the pushrod seal/boot has split or is not seating correctly. (Fig 7)

3. Next, examine the pushrod and the inner part of the seal for any damage or evidence of water entry through the boot. (See red boxes on Fig 1) It is difficult to see fully inside the boot, but a torch will help.

Remember, if the pushrod shows signs of corrosion (after wiping away any grease), boot damage is the likely cause.

If water or rust staining is present on the pushrod, it is a clear sign that the pushrod seal/boot has split or is not seating correctly. (Fig 7)

Following the steps above will help preserve the life of calipers on trucks, trailers and buses. The caliper and service chamber interface is often overlooked, but it is always worth taking a few minutes to check the seal carefully to determine if a new air chamber is needed or not.