When operating a commercial vehicle bodyshop, margins are tight and time is of the essence for each job. Graham O’Neill, CEO of ACIS, explains how to streamline orders and maximise savings.

It is important that businesses not only look for savings in the time spent on jobs, but also the money spent on the products that are required. The savings can be achieved through conversations around where the products are being used and who is using them. In the past, this information was not available; however, with the advancement of technology it is now easily accessible.

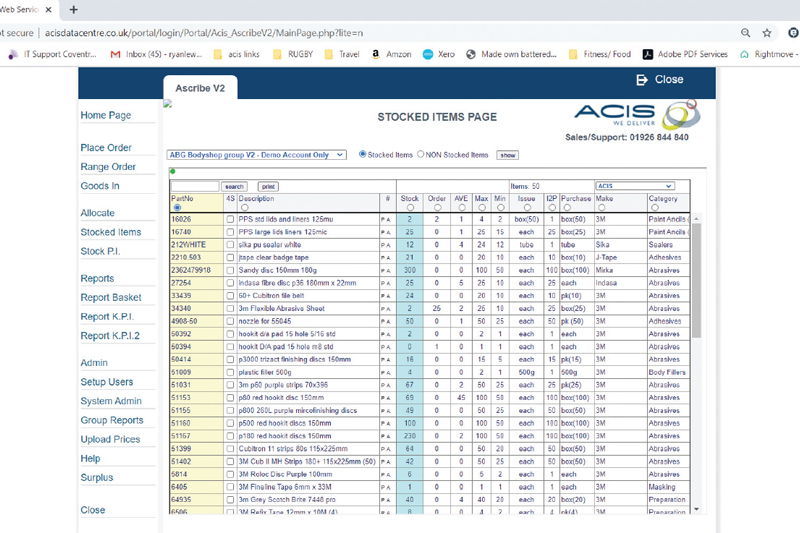

ACIS’s Ascribe system provides full visibility of a business, which enables managers to speak to the technicians on the floor and ask why certain consumables are being used more by technician A than technician B, for example. It can also allow businesses to understand if any of their technicians require training on specific processes, which then promotes a conversation with their distributor (ACIS), who can talk to a manufacturer partner and arrange some training. An example of this is an abrasive disc, which is now being used multiple times before it is changed, when it may have only been used once previously.

From a monetary aspect, most businesses have a rough idea as to what their cost per sold hour is but (with margins being tight), if the cost per job goes up, the profitability goes down. So, having the ability to see figures first hand, in real time, ensures that senior management can catch issues early, find out what the problem is, and put in place steps to fix it.

Another saving is through acquiring knowledge; this is because, as a business, ACIS works with several partners that have years of experience in the industry. So, when Ascribe is installed, there is the ability to put in core stock, which is agreed with the business and tailored to its individual needs.

Streamlining the process

When it comes to streamlining a bodyshop’s ordering process, the traditional way was for a distributor to go in and visit the site to take an order or the bodyshop parts manager walking through checking stock and then placing an order.

This was a labour-intensive process and there was no traceability on the stock, especially when it came to bodyshop consumables (who was using them, where were they going, and what jobs were they being used on).

This lack of traceability would lead to businesses holding (and using) more stock than is required. Whereas for paints, businesses can see exactly where each penny is going with the help of smart scales. However, with the advancement of technology, the Ascribe system has changed this. It has been designed to allocate products to a technician, department, or job number easily, and it knows when the items are at their minimum level so it can automatically reorder them to the agreed level.

This then leads to the bodyshop slowly reducing its overall stock holding because it can easily see how much it is using. This also means the business becomes leaner both from a stock and financial point of view because it has moved away from the traditional method: ordering a certain amount of product each month, potentially resulting in not being able to use all of it, before reordering the same amount the following month, causing dead stock to be sat on the shelves.