Choosing the right wheel aligner

Whether it’s a brand-new workshop or you’re simply going for a replacement, choosing the right wheel aligner for your business can be a complex task. Here Tom Coad, AES UK, provides some guidance to help you arrive at the right choice.

Misaligned wheels on commercial vehicles can lead to issues including premature tyre wear, increased fuel consumption, inconsistent handling, and even increased driver fatigue. Choosing from the extensive range of systems available can be a daunting task. Hopefully, what follows will equip you with the knowledge and insights needed to select the system that perfectly aligns with your needs.

Vehicle types

What types of commercial vehicles are included in your fleet or put through your workshop? Tractor units, trailers, cranes, twin-steer vehicles, light commercial or a combination? Each category has different alignment specifications and requires compatible systems and possible add-ons.

Define your workshop needs and its wheel alignment requirements, including types of vehicles and axle configurations. Consider future possibilities for different types of vehicles.

What is your typical workload? Do you focus repair and maintenance, tyres or accident repair? High-volume operations demand faster systems, while specialised alignments such as post collision repair might need more advanced features.

What is your budget? Commercial vehicle alignment systems range from basic setups to feature-packed all-encompassing. Define your budget early to avoid sticker shock later.

What is my staffing situation? Are your technicians experienced with alignment systems, or do you prioritise user-friendly options? Balancing technical requirements with operator skill is crucial.

Analogue vs digital

The two main commercial alignment systems are:

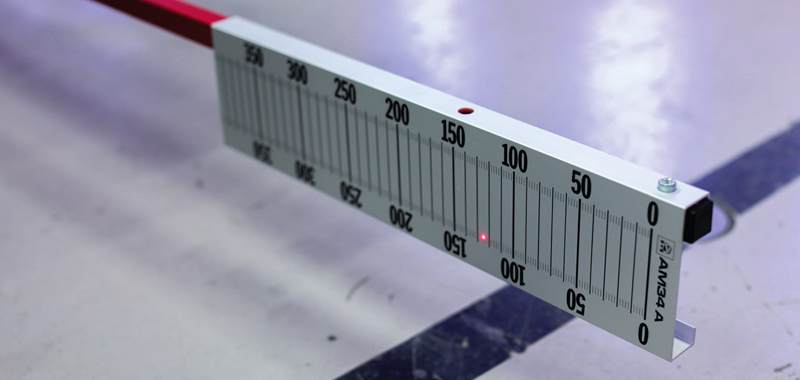

Analogue based systems: these classic setups use analogue measuring devices (usually lasers) mounted on the wheels. They offer a cost-effective entry point but require more manual input and can have limitations in terms of accuracy and adjustable parameters.

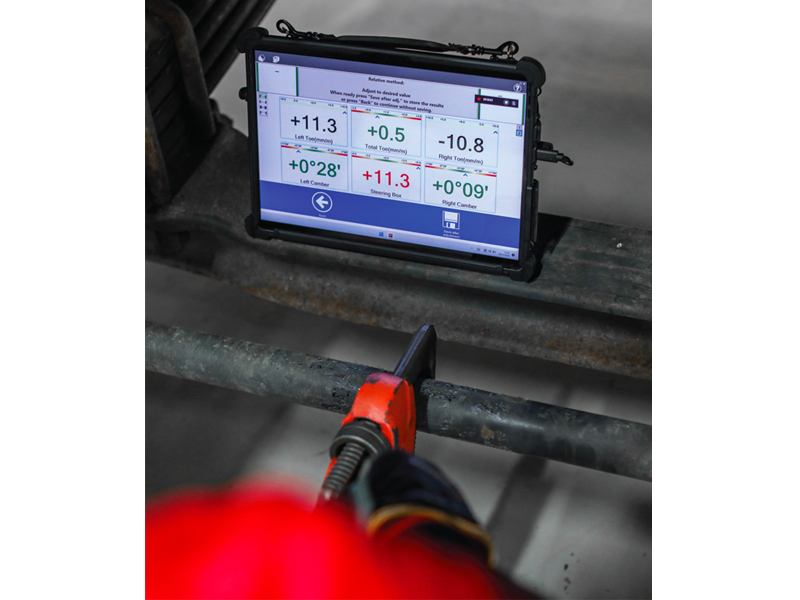

Digital systems: digital systems utilise camera technology to capture wheel angles automatically. They often have superior accuracy, faster measurements, and a broader range of adjustable parameters, but come at a steeper price and are frequently combined with a laptop, PC or tablet in order for the technician to work from live readings.

Choosing between analogue and digital depends on your budget, technician skills, and desired level of precision. While analogue systems might suffice for basic alignments, digital systems offer significant advantages in terms of efficiency, accuracy, and future-proofing your operations.

Feature focus

Once you’ve identified your vehicle needs and chosen your technology base, delve deeper into specific features:

Alignment parameters: how many angles can the system measure and adjust? More options cater to specific alignment issues and future regulatory changes.

- Basic requirements include toe, steeringbox- middle and out-of-square (thrust/skew) angle.

- More advanced requirements include, caster, KPI, max-turn angles and more.

Calibration and service interval: how often does the system need calibration? Frequent calibrations increase downtime and costs. What happens when something breaks can it quickly be repaired or does it have to be shipped away? And does the provider offer a loan system?

Reporting and diagnostics: does the system generate detailed reports for record-keeping and preventive maintenance? Advanced diagnostics can pinpoint potential issues early. Mobility and portability: can the system be moved easily within your workshop or even used on-site with customers? Flexibility can be a valuable asset.

Software updates and support: does the manufacturer offer regular software updates and reliable technical support? Keeping your system current guarantees accuracy and efficiency.

Trustworthy testimonials

Don’t just rely on brochures, spec sheets and sales personnel. Talk to other fleet and workshop managers, industry experts, and technicians. Utilise online forums and reviews to glean unbiased user experiences. Remember, real-world insights trump glossy marketing material any day.

Training and aftersales

Commercial vehicles come in all kinds of configurations; aligning a trailer is a completely different process to a light commercial vehicle. As such, proper training for your technicians is nonnegotiable. Look for a system that offers comprehensive training programs tailored to the specific features and functionalities of their equipment and your vehicles. These programs should cover not only the basic operation of the system but also indepth knowledge of alignment principles, vehicle-specific adjustments, and data analysis. A robust training program and readily available technical support can make all the difference in ensuring your alignment system delivers its full potential.

The price

Remember, the cheapest option isn’t always the best. Consider the total cost of ownership, including purchase price, installation, calibration, maintenance, and return on investment. A more expensive system with greater features could save you money in the long run through increased efficiency and reduced tyre wear.

Align with success

Whether you are wanting to create a revenue stream or save on fuel and tyres for your fleet, choosing the right commercial wheel alignment system is an investment. Once you have considered the points above request demonstrations from suppliers to ascertain strengths and weaknesses.

It’s not just about finding the most advanced gadget; it’s about finding the system that empowers your technicians, optimises your operations, and keeps your commercial vehicles rolling smoothly, safely, and cost-effectively down the road.