Why are workshops turning to induction heating?

It’s time to extinguish that flame and move to induction heating says Greg Ball, sales director, GYS. Here he explains why it’s the go-to method to free seized parts.

Oxyacetylene gas has been used in commercial workshops for as long as we can remember, however with the rising price of gas cylinders and increasing high risk procedures it is time for a new kid on the block. Induction heating is just that, with advancements in technology in the last few years having transformed its functionality to now offer much more than some of the small handheld coil products that have been around for a few years.

Induction heaters offer many advantages over flame. They are precise; only the area near the inductor is heated. Instantaneous; the heat is diffused from the metal’s core in only a few seconds. Capability has also expanded as more powerful models have become available, with the likes of a small handheld tool having an output of 500W to 1Kw. Products now can deliver up to more than 20kw with the most popular models now being around 3.5-4kw. Induction is also extremely safe as there is no flame allowing users to work near flammable areas without causing damage.

Technology in induction heating has developed greatly over the last few years and accordingly, a wide range of induction heaters are now targeted at the automotive maintenance sector. Why are an increasing number of commercial workshops replacing gas flame torches with induction heating? Here’s why: induction heating is exceptionally easy and safe to use without masses of training.

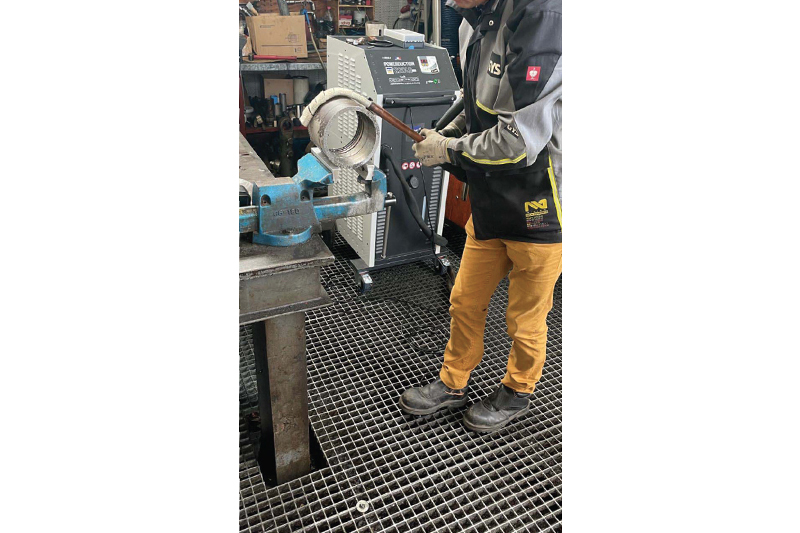

The precise accuracy provided means that the metal elements, be it metal housing or a tie rod, can be heated to very high temperatures in seconds without heating the surrounding area, helping you repair seized drag link ball joints or steering suspension safely and quickly.

Building insurance premiums can also be reduced something that may even negate the initial purchase price of the equipment making induction heating a very cost-effective process on top of the previously mentioned gas and cylinder rental which have much higher running costs than an induction heater.

The heat is on

How does induction heating work? Electromagnets heat the inside of the metal/object itself using a high-frequency AC, causing the object to heat up without using an external source like oxyacetylene. This is much safer and way more versatile than using oxyacetylene gas.

For decades, getting metal to expand has been done using a flame torch, which is extremely dangerous and imprecise. Not anymore. Heat induction is the revolutionary method of heating metal, by using electromagnetic fields. We have been struck by the rate of take up of induction in automotive garages and workshops.

More and more commercial vehicle workshops are making the change to safe and powerful induction heating, the benefits of precision and reduction in costs are fast becoming the reason to make the change for a better commercial workshop.

The GYS Powerduction range includes machines that cater for all applications, with steel and aluminium heating capabilities.

The 110, 160 and 220 models are suitable for the workshop environment with their combination of power and manoeuvrability and can tackle all jobs in a quick and unobtrusive fashion.