Steering is arguably one of the most safety-critical parts of a commercial vehicle and steering components must be properly maintained so a vehicle can perform to optimal levels. Diesel Technic offers advice on dealing with common problems associated with steering components.

The steering pump is an auxiliary unit of the engine that supports power steering. When replacing a steering pump, several installation errors are possible that technicians must be cautious of. To help with these, Diesel Technic, a commercial vehicle spare parts specialist, offer multilingual, illustrated assembly instructions for products of the brand DT Spare Parts, along with troubleshooting guides to replacing steering components, such as pumps.

“Steering pumps need to be checked as often as a general regular maintenance check is completed. In addition, the power steering filter needs to be changed in accordance with the vehicle manufacturer’s specifications,” suggests master commercial vehicle mechanic Lars Mesloh, Group Supervisor Guarantee Management, Diesel Technic AG. “When examining a steering pump, technicians should also check the fill level of hydraulic fluid. Overall indications of a component failure can include leakage, unusual sounds and tight steering.”

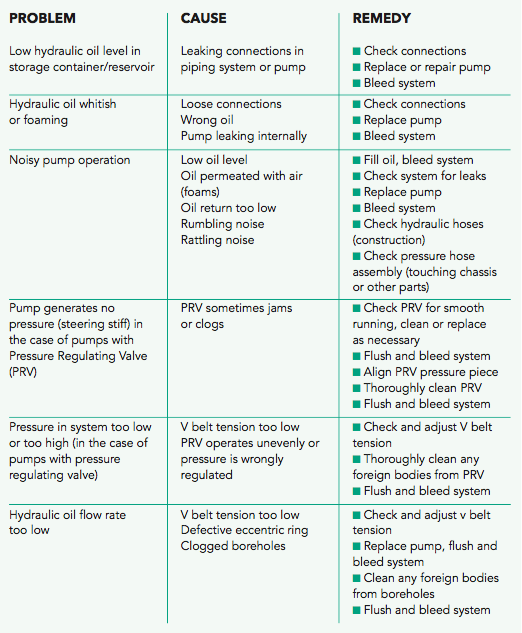

Diesel Technic helps technicians by highlighting the most common problems faced when servicing a steering pump, along with the potential cause and a suggested solution:

Tech tips for steering pump installation

If a problem is found within the steering pump, a replacement may be required. Diesel Technic has some top tech tips on how to properly install a steering pump, so that fleet vehicles are back on the road in no-time.

1. Installation of an incorrect steering pump can cause severe damage to the components of the servo assisted steering mechanism. Therefore, before installation, make sure that the new pump you are installing is identical to that of the old pump. Under no circumstance should steering pumps be dismantled.

2. Before installing new components, check the hydraulic system of the servo assisted steering mechanism for contamination and flush the hydraulic system if necessary. Internal pressure relief valves can be replaced only in combination with the steering pump. Check the function of external pressure relief valves when replacing the steering pump and replace if necessary.

3. Always observe the manufacturer’s instructions when working on steering systems. After completion of the repair, check the tightness of the steering and bleed the system, thereby adhering strictly to the manufacturer’s specifications.

4. Make sure that the hydraulic oil used complies with the manufacturer’s specifications. Hydraulic oil must not be allowed to contaminate local waterways and must be disposed of by a specialised raw materials dealer or at a hazardous waste collection point.

“With steering being such a safety-critical part of a vehicle, having the confidence in fitting a durable, quality product is

essential,” says Lars.

“Experienced Diesel Technic technicians extensively test all of our components to ensure durability and give customers confidence in our products. These tests simulate realistic situations in which the component might perform on a vehicle.”

Diesel Technic offers a two year guarantee across its spare parts range. Further to this, if customers suffer technical problems, distribution partners are fully supported by experienced master mechanics and mechatronics engineers from the commercial vehicle sector.