Frigair provides CVW with a masterclass in compressor fault diagnosis and repair.

In an air conditioning system, the performances of one component affect the performances of the rest. When the air conditioning system fails, the first part that attracts suspicion is the compressor, because it is a delicate component. However, in Frigair partner Sanden’s experience, 30% of compressors replaced during warranty period have not failed; more than 65% are broken due to reasons which are not the fault of the compressor, and less than 5% fail due to a fault in production. Wrong diagnosis and wrong repairs cause high costs to all parties involved.

The components of a standard refrigerant cycle are compressor, condenser, expansion valve and evaporator. The compressor is the hardest working component, the only moving component in the system and is highly engineered. Any adverse conditions elsewhere in the system can cause irrevocable damage.

Fault diagnosis

The main enemies of the compressor are impact damage, dirt, and poor circulation of the refrigerant or oil.

1. IMPACT DAMAGE

Any impact to the vehicle can cause serious damage to the compressor, breaking external parts. Impacts can also affect the correct functioning of the belt drive, creating noise and a general malfunctioning of the compressor.

“Before installing the new compressor, flush the system with approved flushing fluid. Do not flush the condenser as it is likely to make any blockage worse.”

2. DIRT

The refrigerant is pumped from the compressor to the condenser, so must be free from impurities. It’s really important to clean filters regularly to prevent poor performance or damage to the system. Remember, also, to flush the system after a compressor failure – it could be contaminated with particles that can cause severe damage to the valves and, subsequently, to the correct functioning of the compressor.

3. POOR REFRIGERANT/ OIL CIRCULATION

Poor oil and refrigeration circulation will result in insufficient lubrication of the compressor, damaging internal parts. Poor circulation has several potential causes:

Wrong volume of oil/refrigerant

It is important the oil/refrigerant volume matches to that specified by the air conditioning system manufacturer. Too little oil/refrigerant and the internal compressor parts will not be refrigerated/lubricated, and the compressor will fail.

The most difficult situation comes when a vehicle has been in a crash and the repairer does not know the amount of oil lost. In these cases the best option is to flush the system and refill with the amount of oil the air conditioning system manufacturer recommends.

Leaks

If any part of the system has a leak, the oil/refrigerant circulation will not be correct. Special attention must be given to the receiver drier, which must be changed after a compressor replacement. Also check that the expansion valve is properly functioning and that any systems filters are properly calibrated. With small leaks, the refrigerant escapes slowly. The pressure sensor will protect the compressor from damage caused by a quick leak (such as a broken condenser) but not in the case of a small leak.

Fault diagnosis: recommended procedure

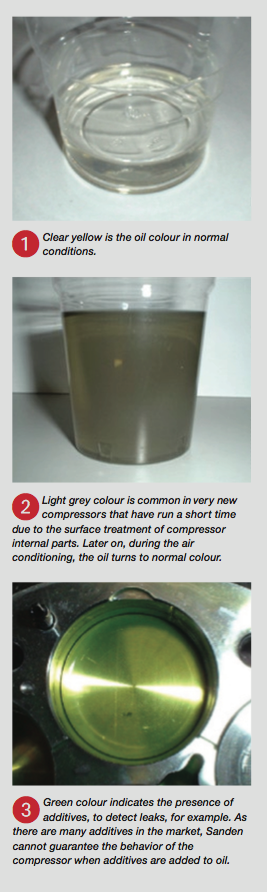

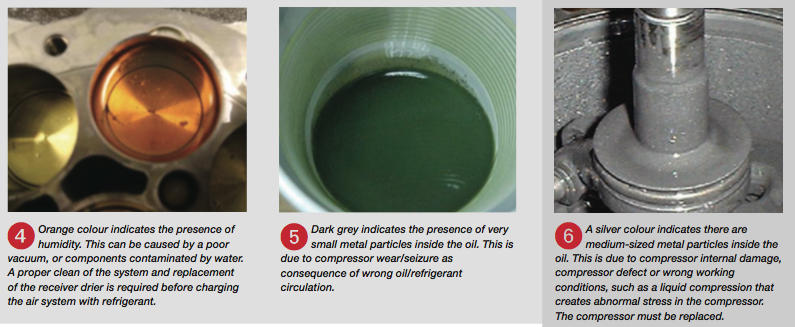

Before changing the compressor, check all the symptoms. Oil condition is an excellent tool in helping to make the right diagnosis and to confirm if it is the compressor at fault with the need to disassemble the compressor.

COMPRESSOR PROBLEMS

- Overheating – you can see the label blistering

- Burned clutch

- Short circuit/open coil

- Short circuit coil

- Condensation problems

- Noises – Air conditioning diagnosis is a difficult matter. The compressor itself creates noise and other components also create noise in the vehicle.

Noise reduction

Proper design of the air conditioning system (compressor bracket, hoses, pipes, HVAC insulation, etc.) is key to avoid noises. In case of abnormal noise, try to identify the conditions under which noise appears, the kind of noise and the repeatability of the noise under such conditions – for example: hot/cold days; at certain rpms. When the compressor is engaged, the charge to the engine changes, so it is normal to notice a difference in the quality of the perceived noise.

Protect your warranty

Warranty on compressors will only be granted for defects caused during manufacturing. It’s also important to carry out the following procedures:

■ Before installing the new compressor, flush the system with approved flushing fluid. Do not flush the condenser as it is likely to make any blockage worse.

■ Always replace the receiver drier/accumulator when mounting a new compressor.

■ Always replace the expansion valve or orifice tube, because most of the particles or other contaminates in the system block the orifice.

■ Remember: new compressors already come supplied with the correct amount and type of oil.

■ Once fitted, carry out a complete system check to ensure that the pressures are correct. If the compressor is subject to incorrect pressure, it will be damaged.